Method used for improving measurement accuracy of stagnation total temperature probe

A probe measurement and accuracy technology, applied in the field of improving the measurement accuracy of stagnant total temperature probes, can solve the problems of increasing airflow temperature pulsation, increasing airflow velocity, uneven distribution, etc., to improve measurement accuracy and reduce speed Error, the effect of uniform airflow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The flow control method of the invention can be used for flow control in various stagnation chambers including stagnation total temperature probes and shielded total temperature probes.

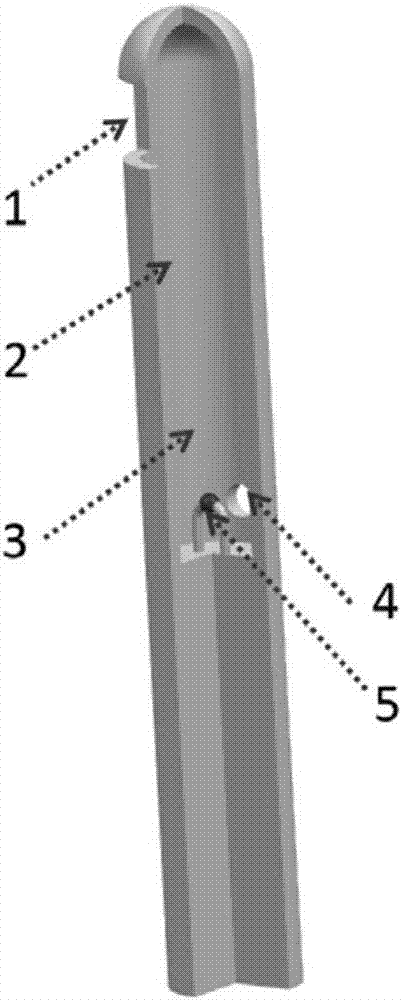

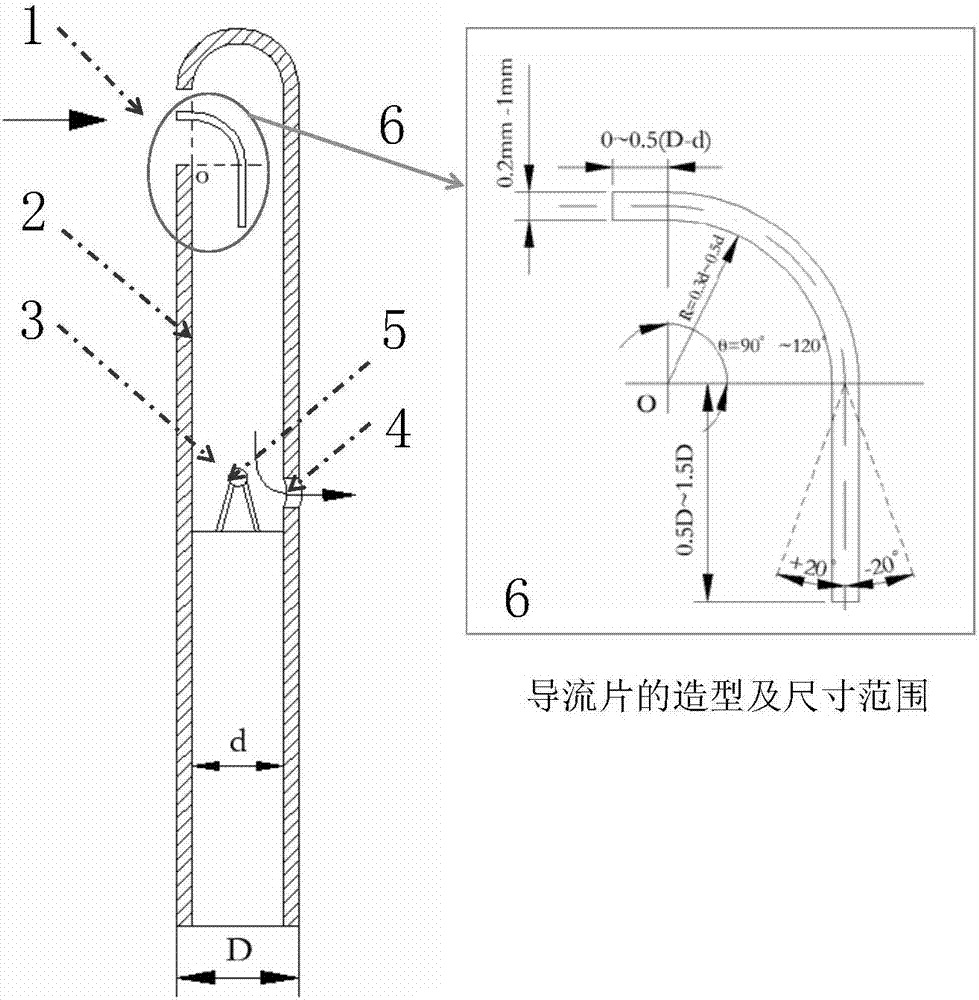

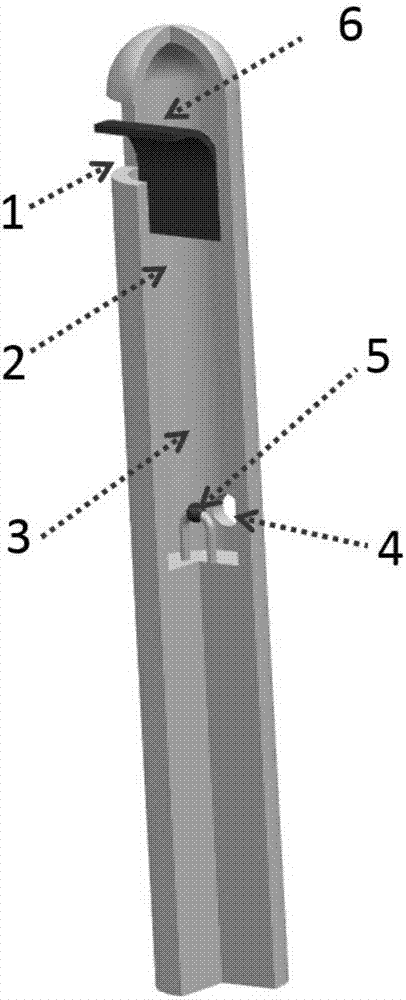

[0029] like figure 2 and image 3 As shown, in the embodiment of the present invention, a deflector 6 is arranged between the stagnation cover inlet 1 of a stagnation total temperature probe and the stagnation inner wall 2, and the area of the stagnation cover inlet 1 is divided into two parts of 1:2. In part, the deflector 6 is fixed by the inner wall 2 of the stagnation chamber.

[0030] The extended length of the deflector 6 in the stagnation chamber 3 is determined according to the length and diameter of the stagnation chamber 3 and the actual flow inside the stagnation chamber. The length of the flow sheet.

[0031] The stagnation type total temperature probe with deflector designed by the method provided by the present invention is as follows: image 3 shown.

[0032] Num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com