A method for manufacturing electromagnetic induction heating film and electromagnetic induction heating film

A technology of electromagnetic induction heating and production method, applied in the field of electromagnetic induction heating film production and electromagnetic induction heating film, can solve the problem of large attenuation range of output power of electromagnetic induction heating film, reduce silver dissociation migration, reduce heating power Attenuation, reducing the effect of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

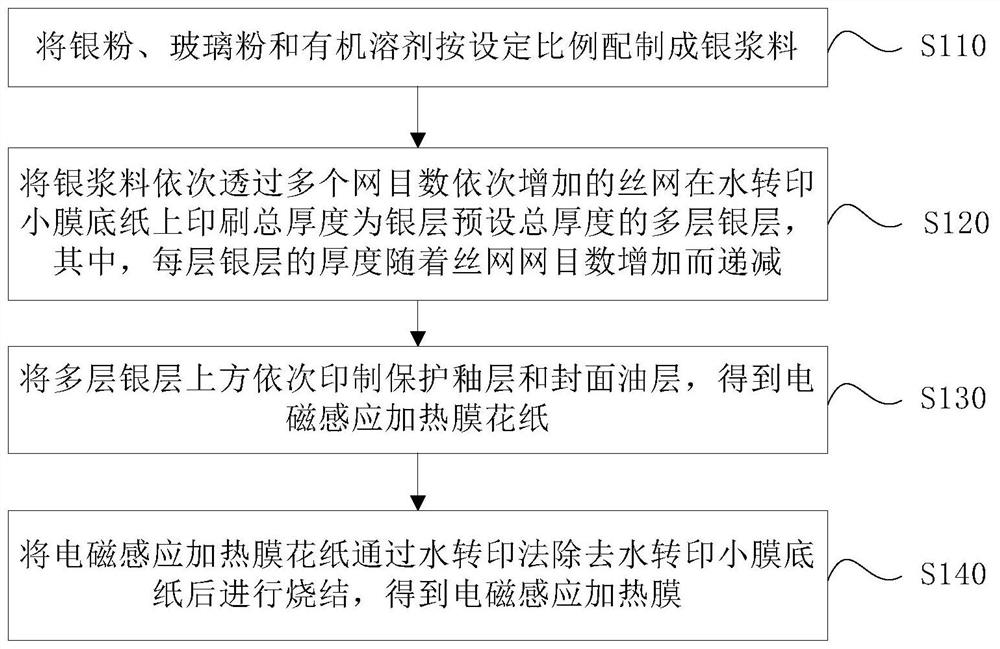

[0046] see figure 1 , is a schematic flow chart of a method for manufacturing an electromagnetic induction heating film provided in the present application. Such as figure 1 As shown, the electromagnetic induction heating film manufacturing method provided by the present application specifically includes the following steps:

[0047] Step S110: Silver powder, glass powder and organic solvent are prepared in a set ratio to form a silver paste.

[0048] Specifically, the set proportions include: 60-85 wt% of silver powder, 2-5 wt% of glass powder, and 10-38 wt% of organic solvent. Wherein, the higher the proportion of silver powder is, the denser the silver particles in the silver layer made from the silver paste will be. In this embodiment, the specific mass proportions of the materials used to configure the silver paste are: silver powder 80wt%, glass powder 3wt%, and organic solvent 17wt%. Mix the materials evenly with a three-roll rolling mill, and remove air bubbles in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com