Circuit Board Assembly And Mehtod For Manufacturing The Same

A technology for circuit substrates and assemblies, applied in circuits, printed circuits, printed circuits, etc., can solve problems such as high melting point and inability to solder other components to connecting terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

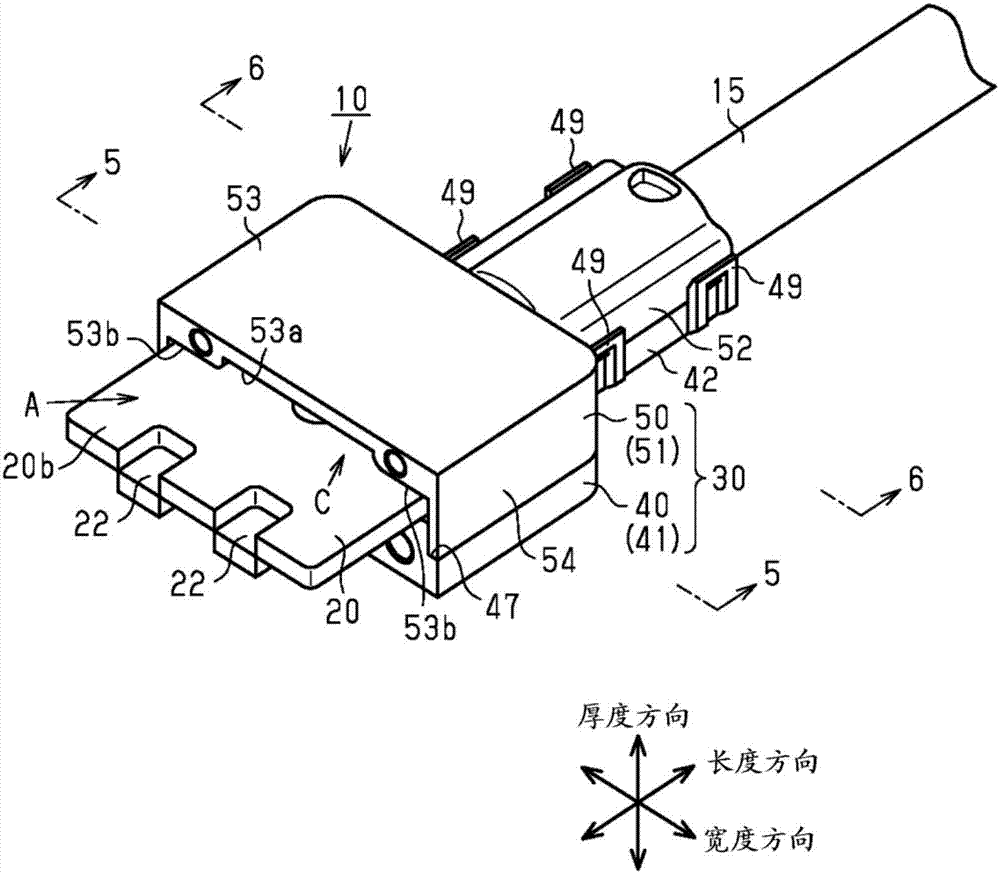

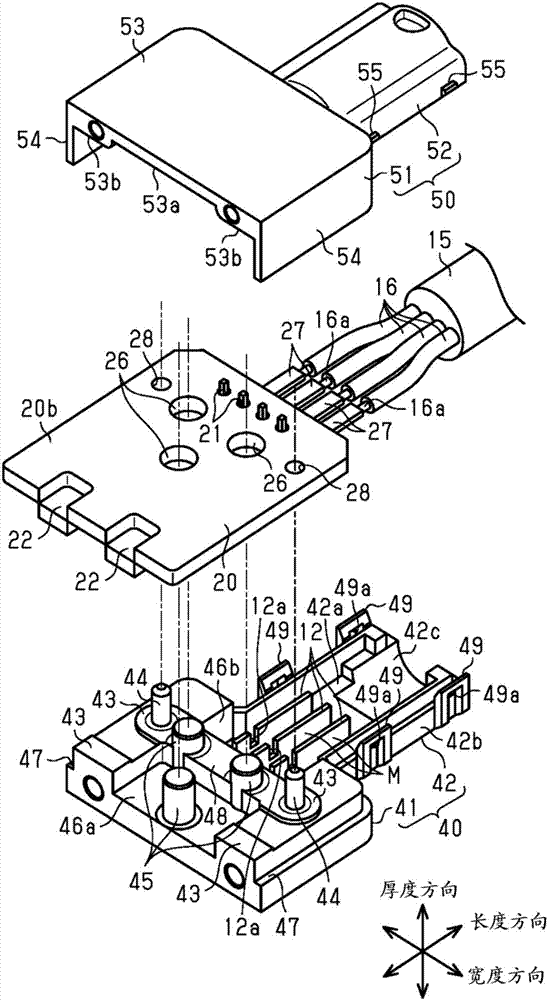

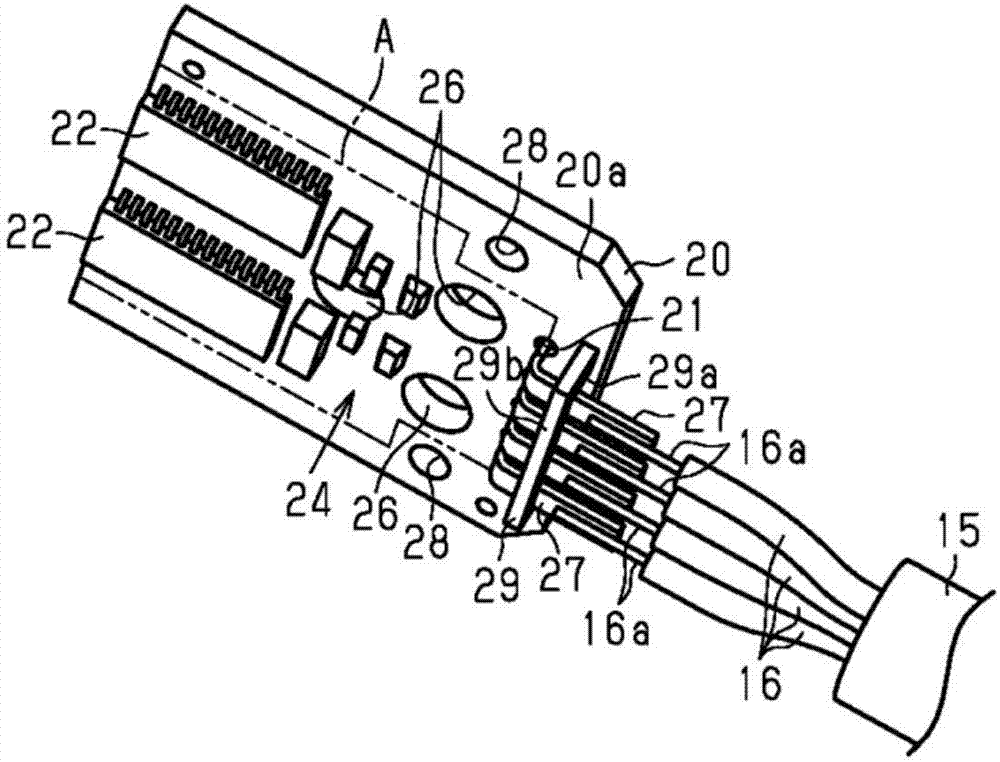

[0023] Below, refer to Figure 1 to Figure 9 A circuit board assembly, a final circuit board assembly, and a method for manufacturing the final circuit board assembly according to one embodiment of the present invention will be described. Such as figure 1 , figure 2 As shown, the circuit board assembly 10 is composed of a circuit board 20 and a cover 30 covering a part of the circuit board 20 .

[0024] Such as figure 2 As shown, the circuit board 20 is formed in a substantially quadrilateral plate shape and has a first board plane 20a (refer to image 3 ) and the second substrate plane 20b. In addition, in this specification as figure 1 As shown, the direction in which the cable 15 described later extends is referred to as the longitudinal direction, and the direction perpendicular to the longitudinal direction and the thickness direction of the circuit board 20 is referred to as the width direction. exist figure 2 In the thickness direction, the lower surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com