Vacuum spraying and filtering device

A filtration device and a technology of vacuum spraying, which are applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of polluted air, difficult to clean, and the filtration effect cannot meet the requirements, so as to increase the number of filtration and the filtration effect is good. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

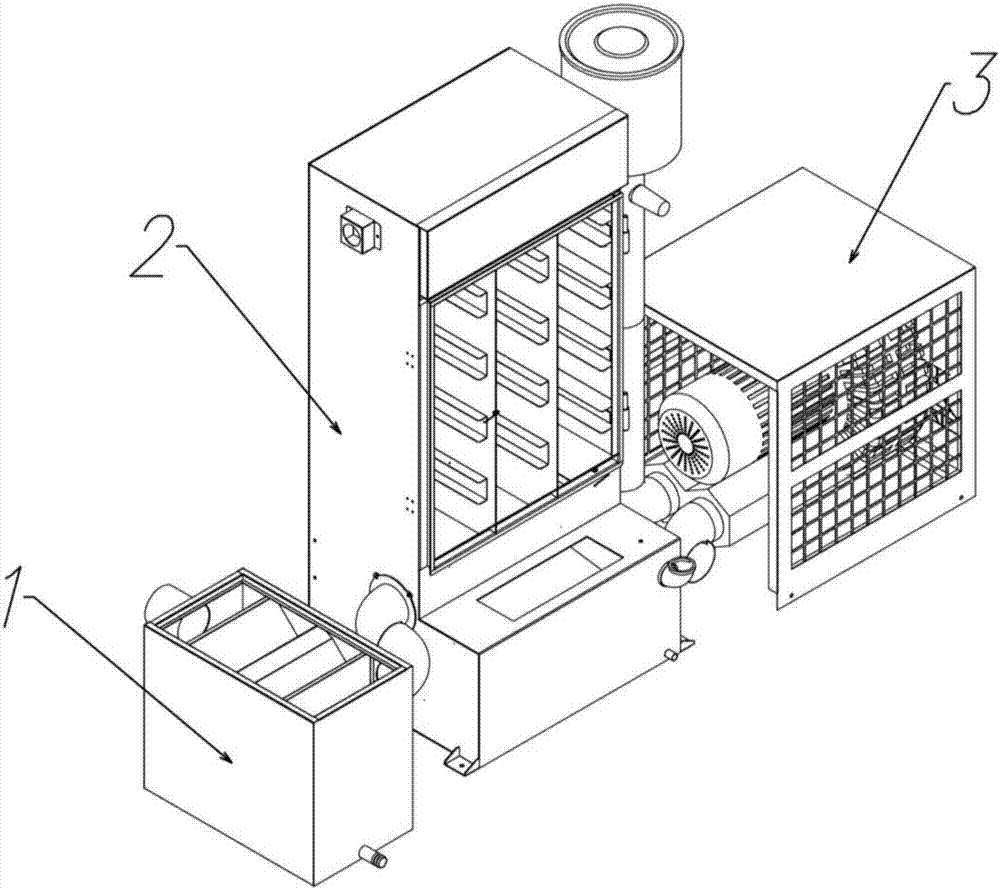

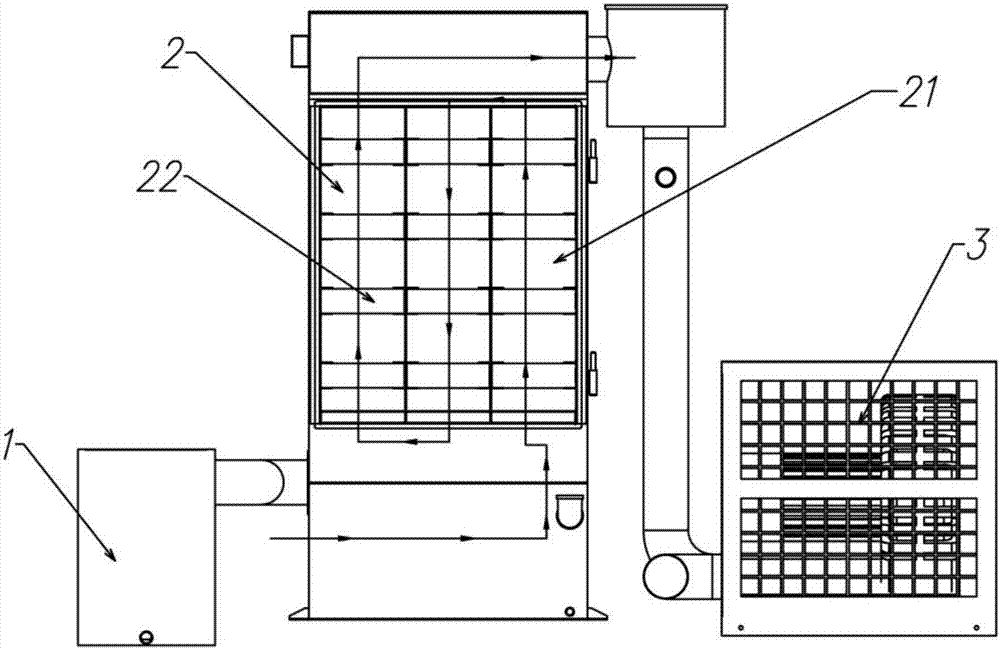

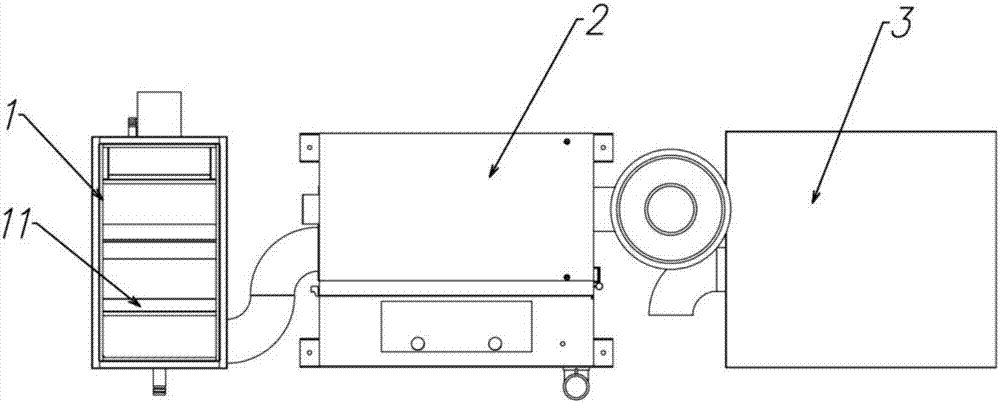

[0021] Such as Figure 1 to Figure 4 As shown, the vacuum spraying filter device of the present invention includes a primary filter box 1, a secondary filter box 2 and a vacuum pump 3, and the primary filter box 1 has an air inlet and an air outlet, and the air containing the paint flows from the primary The air inlet of filter box 1 leads into described primary filter box 1, and described primary filter box 1 is connected with described secondary filter box 2 by pipeline, and described secondary filter box 2 is connected vacuum pump 3 by pipeline, and described A plurality of filter plates 11 are vertically spaced in the primary filter box 1, and the air containing paint needs to pass through each filter plate 11, and each filter plate 11 is provided with a plurality of filter holes through the surface, and the diameter of the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com