An adjustable led module automatic glue filling machine

An LED module and adjustable technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of small enterprises, expensive purchase funds, and inability to fill different types of LED modules, so as to improve the production type, The effect of increasing the survival rate and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

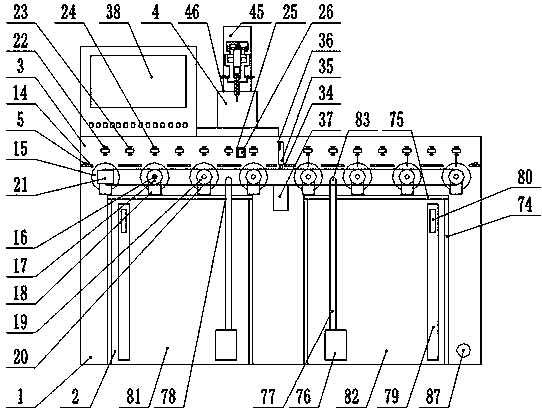

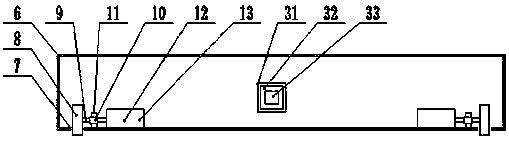

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-8As shown, an adjustable LED module automatic glue filling machine includes a frame 1, the frame 1 is fixedly installed on the ground, a glue bucket 2 is fixedly installed in the frame 1, and a side of the upper surface of the frame 1 is provided with Boss 3, on which a mobile glue filling mechanical arm 4 is fixedly installed, and an adjustable and fixed platform device is arranged above the frame 1, and the adjusted and fixed platform device is fixedly installed on the left and right ends of the frame 1 by adjusting guide rails 5. The transmission device located at the center of the frame 1, the adjustment platform located on the other side of the frame 1 and the fixing device located above the frame 1 are composed together. The gear holes 7 at the four corners of the lower surface of the body 6, the gear one 8 positioned in the gear hole 7, the gear shaft one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com