Shear type anti-winding anti-overloading bag breaking machine for garbage

An anti-overload, shear-type technology, which is applied in the directions of cutting and unsealing, packaging, transportation and packaging, etc., can solve problems such as violent damage to equipment, failure of bag breaking equipment to meet equipment design requirements, and round roll winding, so as to reduce equipment maintenance rate , the process can be improved, and the effect of avoiding violent destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

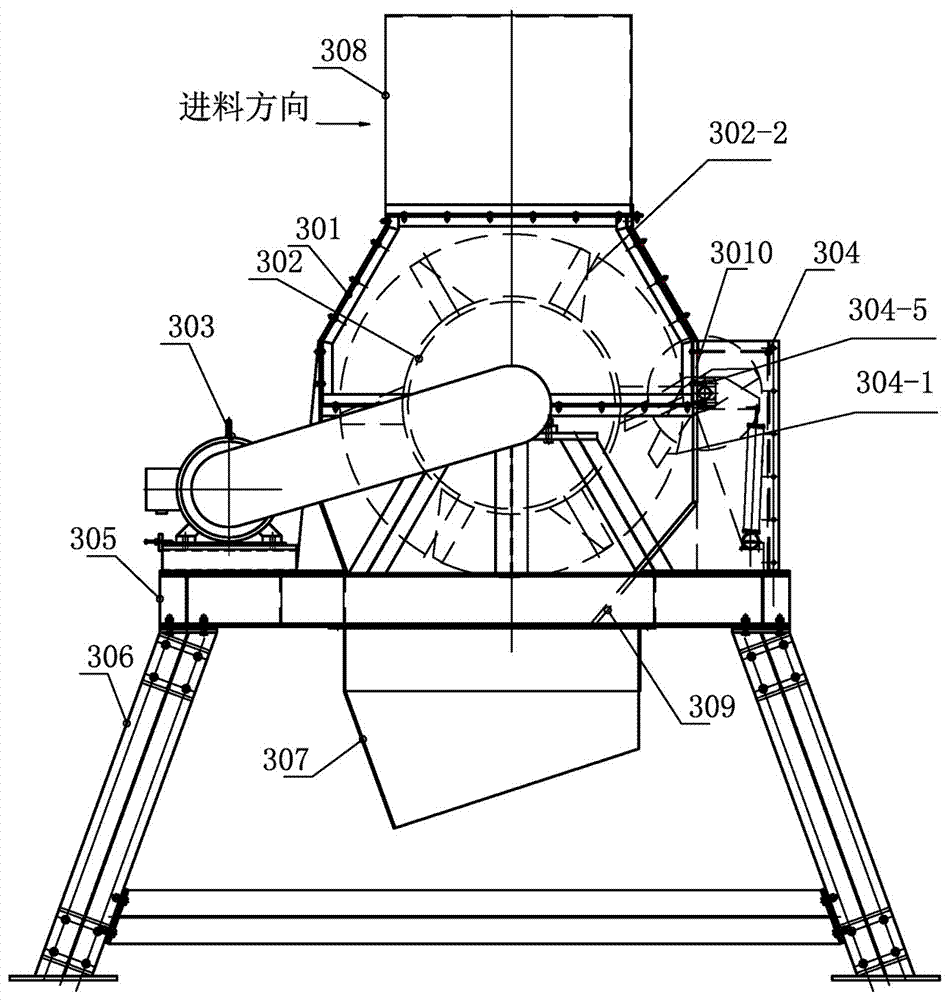

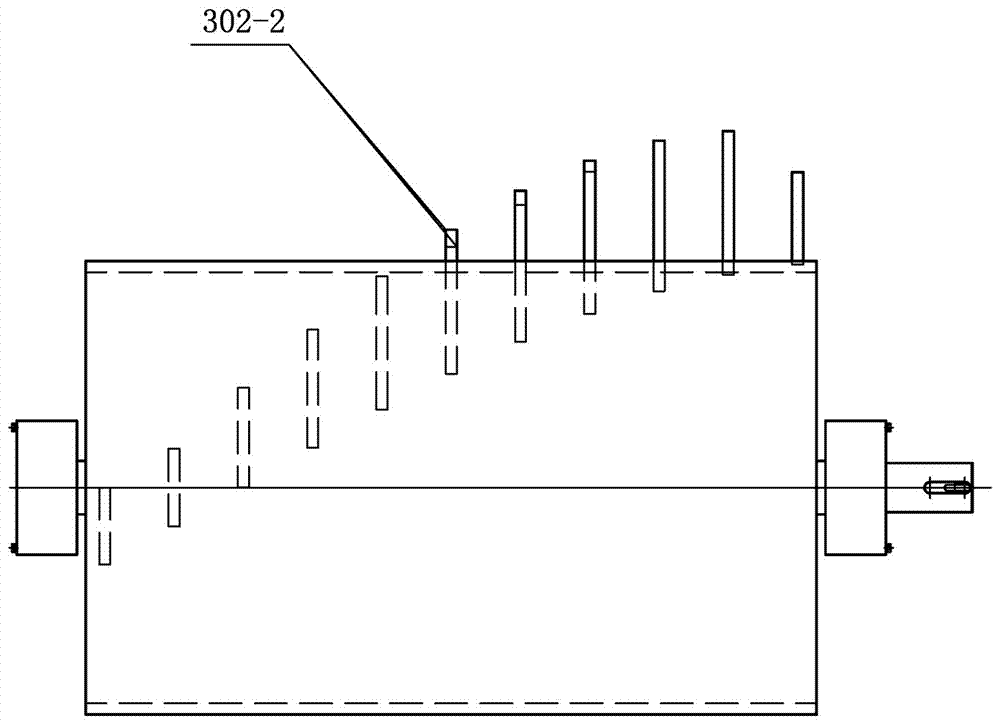

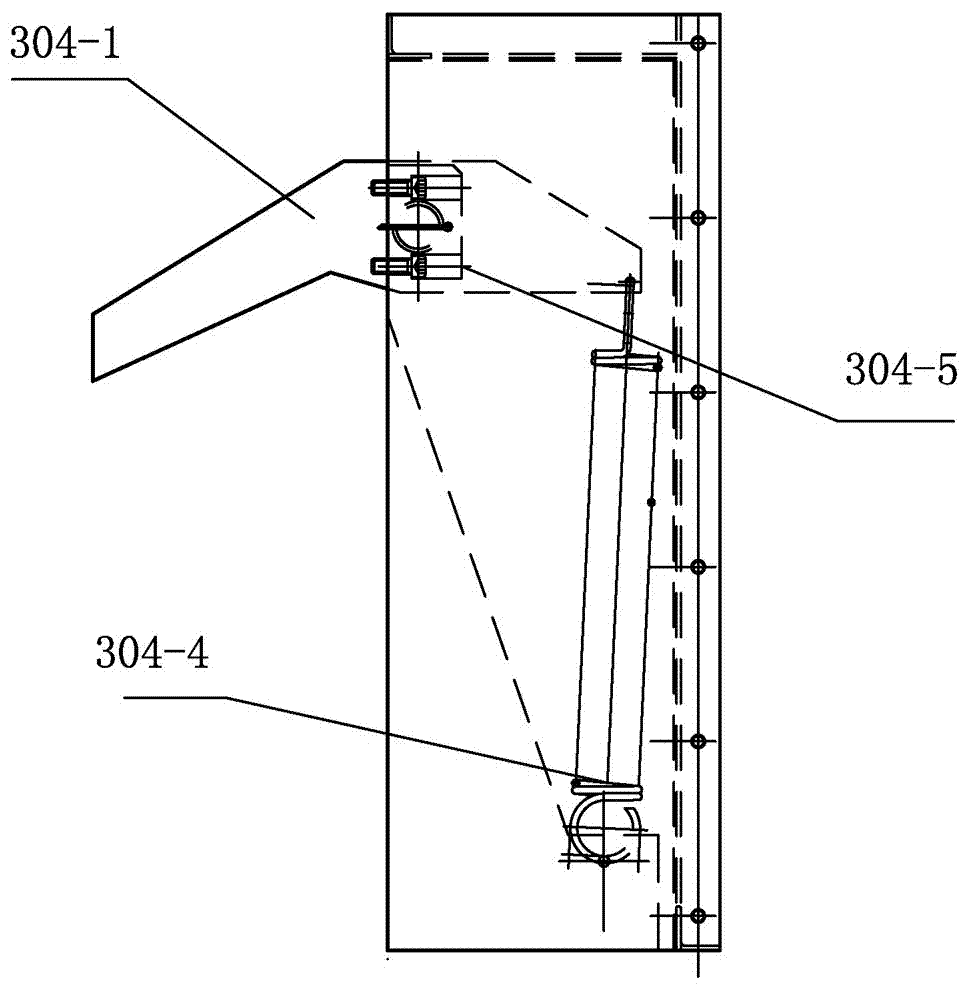

[0022] Such as figure 1 , 2 , 3, and 4, the present invention provides a kind of anti-winding and anti-overload bag breaking machine for garbage shearing, which consists of a housing 301, a feeding hopper 8, a round roller 302, a bag breaking knife 302-2, a self-adjusting anti- The overload fixed knife device 304, the power overload prevention device 303, the support frame 306, the lower hopper 307 and the platform 305 are composed.

[0023] The box type installed on the platform 305 at the top of the support frame 306 is similar to a circular shell 301. A feed hopper 308 is installed on the top of the shell 301. The shell 301 is connected to the platform 305 by welding. The feed hopper 308 is arranged on the oblique top of the equipment so that the The material direction is tangent to the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com