Feeding device

A material storage and material technology, applied in the field of feeding devices, can solve the problems of powder agglomeration, arching, sticking cabin, etc., to improve the conveying efficiency, ensure normal implementation, and solve the effect of powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

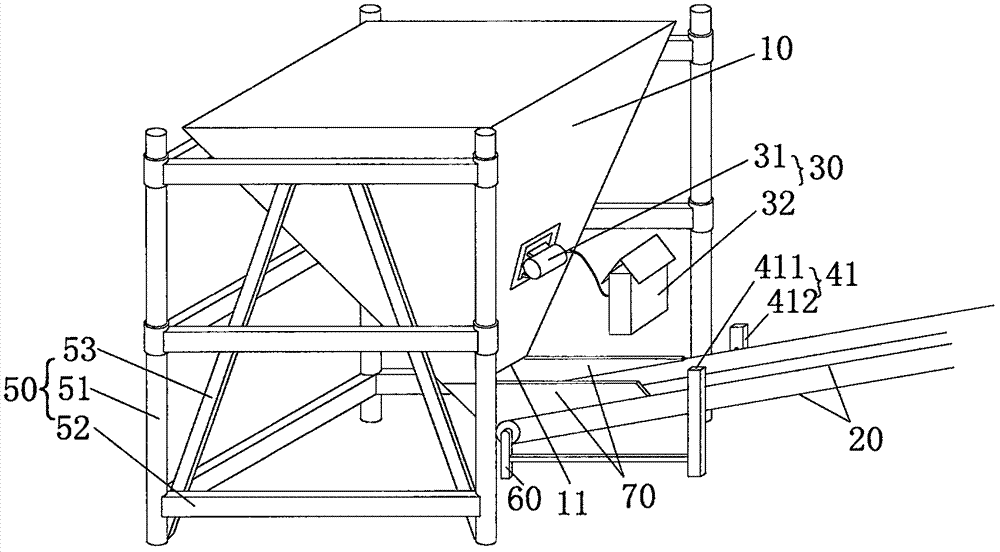

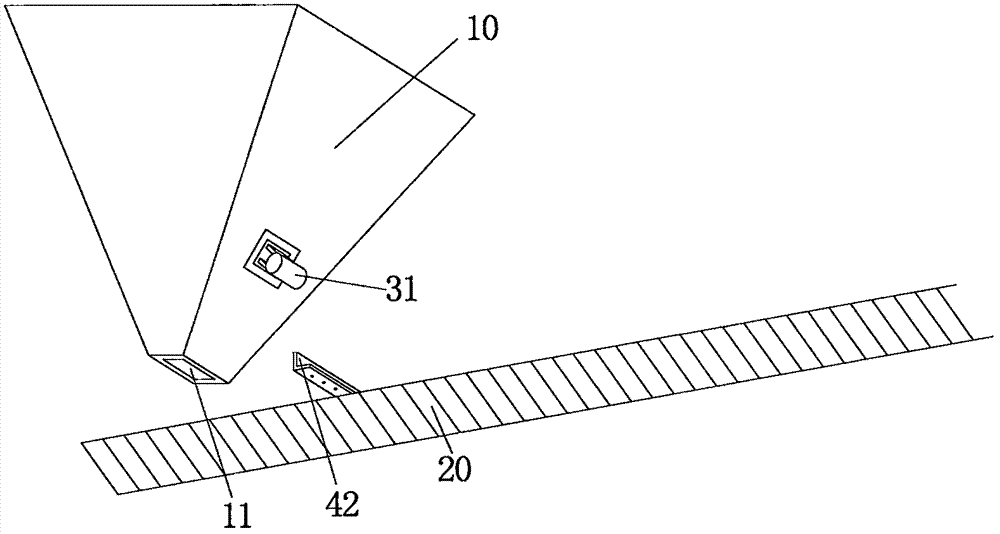

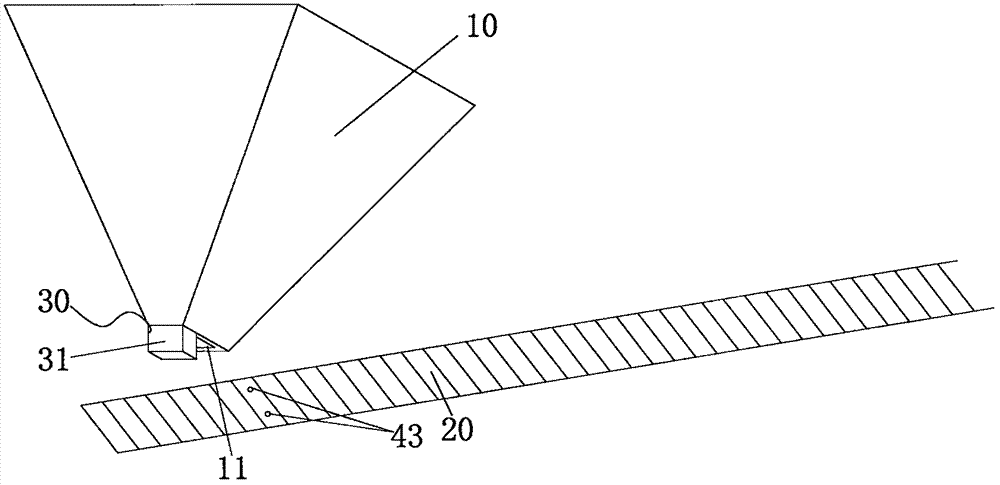

[0028] Further, as figure 1 As shown, as the first embodiment of the present invention, the detection mechanism can be configured to include a signal generator 41, the signal generator 41 includes a signal emitting element 411 and a signal receiving element 412, and the signal emitting element 411 and the signal receiving element 412 are arranged oppositely On both sides of the conveyor belt 20 , according to the on-off of the signal transmitting element 411 and the signal receiving element 412 , it is detected whether the conveying amount of the material on the conveyor belt 20 reaches a set value.

[0029] With this configuration, the start or stop of the vibrating mechanism 30 is controlled by detecting whether the conveying volume of the material on the conveyor belt 20 reaches the set value according to the on-off of the signal transmitting element 411 and the signal receiving element 412 . Specifically, as a specific embodiment of the present invention, the signal transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com