Epoxy composite material with high heat conductivity and preparation method thereof

A composite material, high thermal conductivity technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of large interlayer thermal resistance, disordered graphene stacking, large gaps, etc., to achieve the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Prepare a uniform mixture of epoxy resin and curing agent. Weigh 60 g of bisphenol A epoxy resin, then add 20 g of p-chloroaniline methane, stir magnetically for 1 h at 100 °C to fully dissolve the curing agent, and obtain a uniform mixed solution;

[0028] (2) The epoxy mixture prepared in the previous step was cast into a commercial melamine sponge, and then degassed several times under a certain degree of vacuum at 120 °C, so that the epoxy fully filled the pores inside the sponge. Subsequently, the temperature was raised to 150 °C for pre-curing for 2 h, and then the temperature was further increased to 180 °C for curing for 2.5 h. Demoulding gave the final composite material, denoted EP / MF.

Embodiment 2

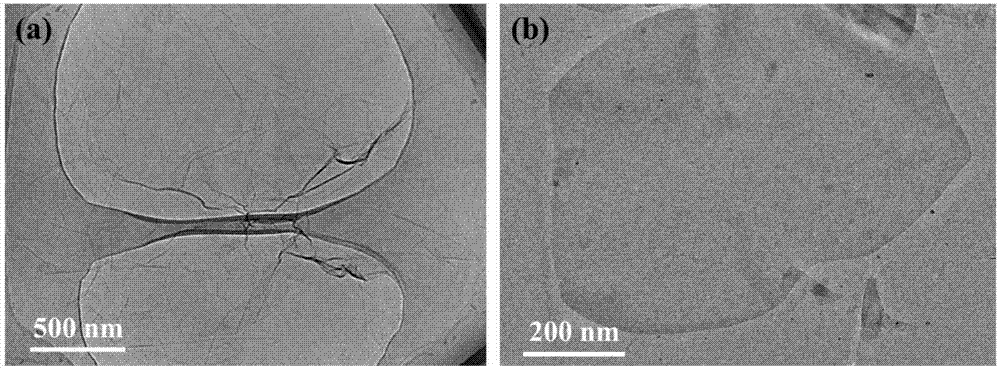

[0030] (1) Weigh 2 g of boron nitride into 200 ml of isopropanol, sonicate for 18 h at room temperature in a 250W sonicator, and then centrifuge at 1000 rpm for 20 min, and take the boron nitride nanosheets ( BNNS) dispersion liquid for use, the concentration of dispersion liquid is about 1 mg / ml; then add 25 ml of deionized water to 25 ml of peeled BNNS dispersion liquid to prepare 0.5 mg / ml BNNS isopropanol / water dispersion liquid ;

[0031] (2) Disperse graphene oxide (GO) in water to obtain a uniform dispersion with a concentration of 1 mg / ml;

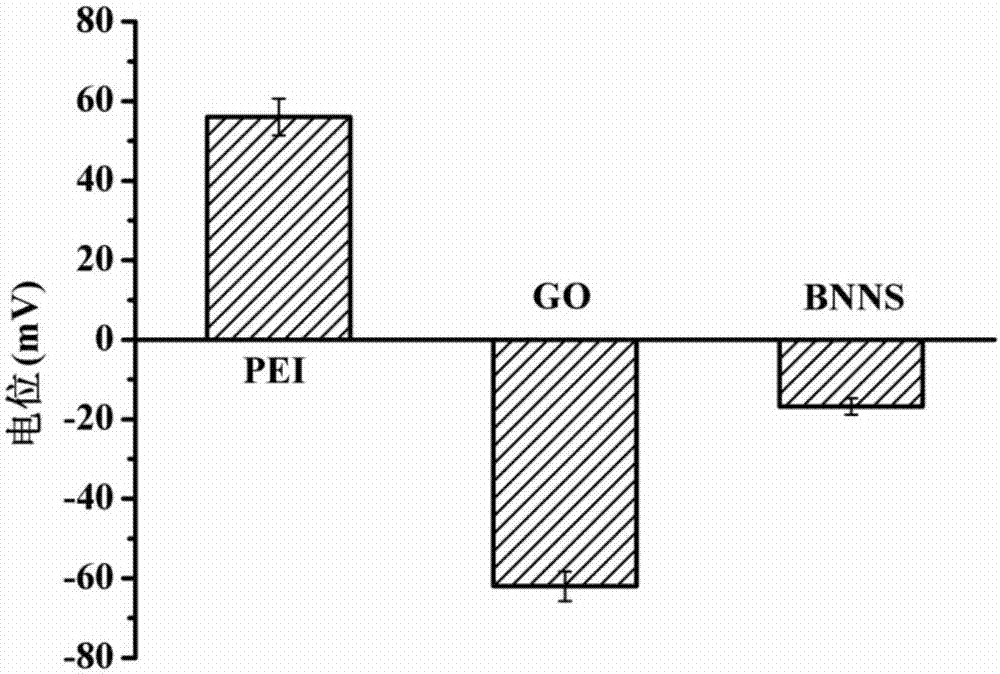

[0032] (3) Prepare an aqueous solution of polyethyleneimine (PEI) with a concentration of 1 mg / ml;

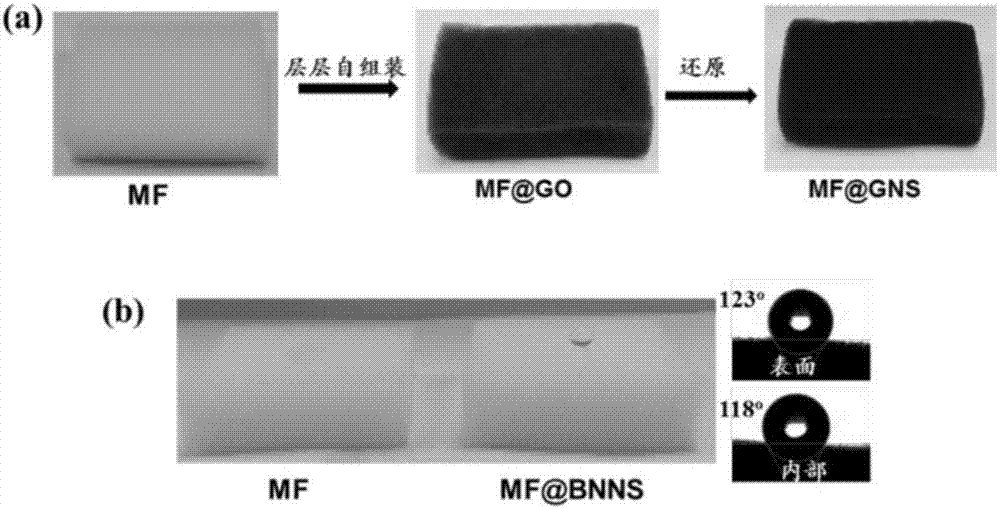

[0033] (4) A commercial melamine sponge of a certain size was first soaked in PEI aqueous solution for 2 min, rinsed with deionized water for several times, and then immersed in GO aqueous dispersion or BNNS isopropanol / water dispersion for 2 min. Then rinse the sponge several times with deionized water. Repeat the above steps fo...

Embodiment 3

[0039] (1) Weigh 2 g of boron nitride into 200 ml of isopropanol, sonicate for 18 h at room temperature in a 250W sonicator, and then centrifuge at 1000 rpm for 20 min, and take the boron nitride nanosheets ( BNNS) dispersion liquid for use, the concentration of dispersion liquid is about 1 mg / ml; then add 25 ml of deionized water to 25 ml of peeled BNNS dispersion liquid to prepare 0.5 mg / ml BNNS isopropanol / water dispersion liquid ;

[0040] (2) Disperse graphene oxide (GO) in water to obtain a uniform dispersion with a concentration of 1 mg / ml;

[0041] (3) Prepare an aqueous solution of polyethyleneimine (PEI) with a concentration of 1 mg / ml;

[0042] (4) A commercial melamine sponge of a certain size was first soaked in PEI aqueous solution for 2 min, rinsed with deionized water for several times, and then immersed in GO aqueous dispersion or BNNS isopropanol / water dispersion for 2 min. Then rinse the sponge several times with deionized water. Repeat the above steps fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com