Preparation method of LED cold light solidified ink binder

A linking material and luminescent technology, applied in ink, household utensils, applications, etc., can solve the problems of difficult cleaning and disinfection, large loss, energy consumption, etc., and achieve excellent flexibility, abrasion resistance, and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] raw material A

[0019] TDI 0.5moL,

[0020] HDI 0.5moL;

[0021] raw material B

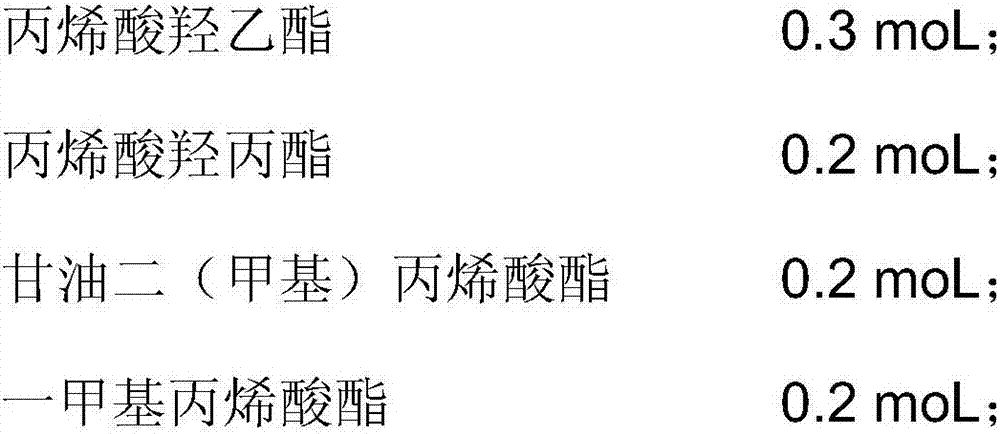

[0022]

[0023] raw material C

[0024] Polytetrahydrofuran 0.15moL;

[0025] The preparation method is as follows:

[0026] Put the raw material A and the catalyst (organotin, the addition amount is 0.1-3% of the total feeding amount) into the kettle, start the stirring, and let in dry nitrogen. The mixture of raw material B and raw material C is added dropwise, and the reaction is kept at 40-75°C for 1.5-5 hours until the NCO reaction is complete and the reaction ends, and the resin of the present invention is obtained.

Embodiment 2

[0028] raw material A

[0029] TDI 0.3moL,

[0030] HDI 0.3moL,

[0031] IPDI 0.2moL,

[0032] MDI 0.2moL,

[0033] raw material B

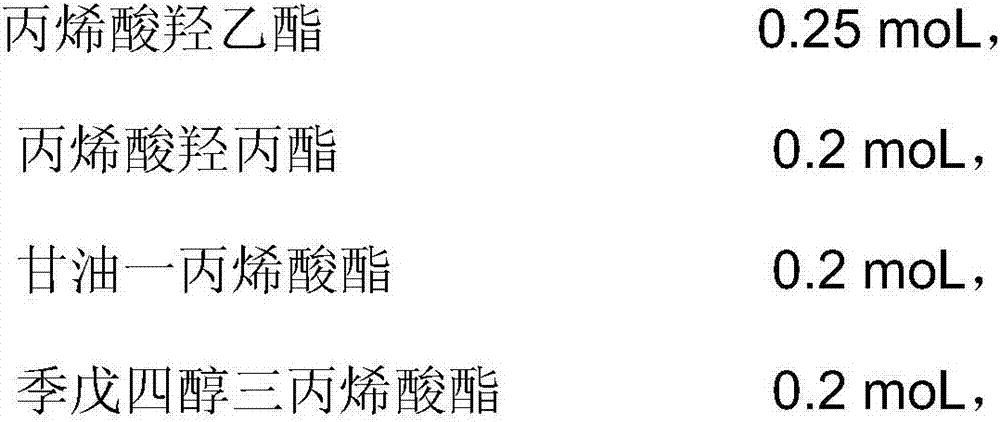

[0034]

[0035] raw material C

[0036] Polytetramethylene ether glycol 0.2moL;

[0037] The preparation method is as follows:

[0038] Put the raw material A and the catalyst (organotin, the addition amount is 0.1-0.3% of the total feeding amount) into the kettle, start stirring, feed dry nitrogen, and drop the mixture of raw material B and raw material C. Insulate and react at 40-75° C. for 1.5-5 hours until the NCO reaction is complete and the end point of the reaction is obtained to obtain the resin of the present invention.

Embodiment 3

[0040] raw material A

[0041] IPDI 0.5moL,

[0042] MDI 0.5moL,

[0043] raw material B

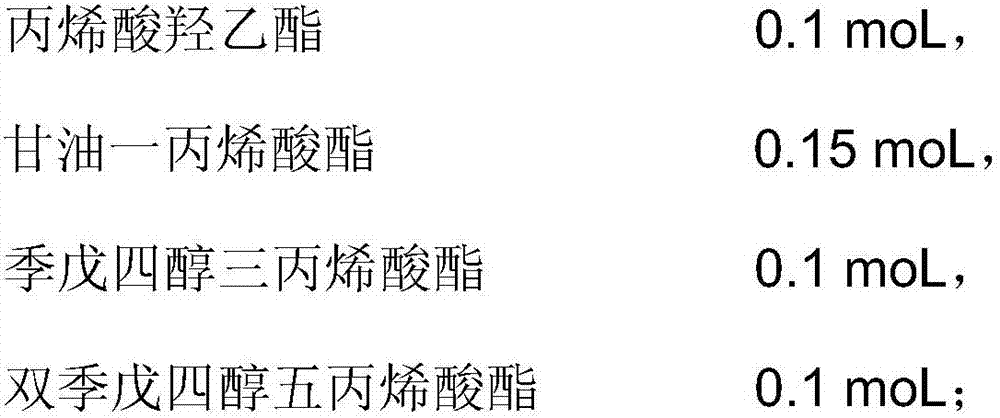

[0044]

[0045] raw material C

[0046] Polytetrahydrofuran 0.2moL,

[0047] Polytetramethylene ether glycol 0.4moL;

[0048] The preparation method is as follows:

[0049] Put the raw material A and the catalyst (organotin, the addition amount is 0.1-0.3% of the total feeding amount) into the kettle, start stirring, feed dry nitrogen, and add the mixture of raw material A and raw material C dropwise. Insulate and react at 40-75° C. for 1.5-5 hours until the NCO reaction is complete and the end point of the reaction is obtained to obtain the resin of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com