Coffee essence preparation method

A coffee essence and vanillin technology, applied in the directions of essential oils/spice, fat generation, etc., can solve the problems of excessive burnt aroma, inability to satisfy consumers, and the coffee taste is not strong, so as to increase the rich coffee taste and avoid volatilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

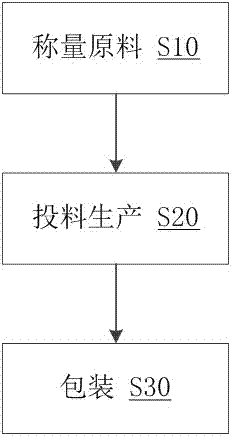

[0026] see figure 1 It is a step diagram of the method for preparing coffee essence in Example 1 of the present invention, a method for preparing coffee essence, which is characterized in that it includes the following steps:

[0027] S10 weighs raw materials;

[0028] S20 feed production;

[0029] S30 packaging;

[0030] Among them, in S10, the weighing raw materials and the proportioning ratio are as follows (percentage by weight): 0.07% betapropiolactone, 0.07% Kangyonglu gram oil, 0.09% benzoic acid, 0.25% n-acetic acid, and 0.36% ethyl acetate , methyl maltol 0.36%, diacetyl 0.29%, furfuryl mercaptan 0.6%, jujube extract 9%, vanillin 8%, coffee extract 18%, ethanol 8%, and the balance is distilled water;

[0031] Among them, S20 includes the following steps:

[0032] S201, add vanillin, methyl maltol, coffee extract, red date extract, ethanol;

[0033] S202, put in ethanol

[0034] S203, heating to 60°C;

[0035] S204, stirring until the solid powder dissolves;

...

Embodiment 2

[0040] The preparation process of this example is the same as that of Example 1, the difference lies in the weighing ratio of raw materials. The weighing ratio of raw materials in this example is as follows: 0.09% of betapropiolactone, 0.09% of Kangyonglu gram oil, 0.11% of benzoic acid, N-acetic acid 0.29%, ethyl acetate 0.4%, methyl maltol 0.4%, diacetyl 0.35%, furfuryl mercaptan 0.8%, jujube extract 11%, vanillin 10%, coffee extract 20%, ethanol 10%, and the balance is distilled water.

Embodiment 3

[0042] The preparation process of this example is the same as that of Example 1, the difference lies in the weighing ratio of raw materials. The weighing ratio of raw materials in this example is as follows: 0.072% of betapropiolactone, 0.072% of Kangyonglu gram oil, 0.095% of benzoic acid, N-acetic acid 0.26%, ethyl acetate 0.37%, methyl maltol 0.37%, diacetyl 0.3%, furfuryl mercaptan 0.7%, jujube extract 9.5%, vanillin 8.5%, coffee extract 19%, ethanol 8.3%, and the balance is distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com