Method for coating inhaul cable body with PVF film

A cable body and wide edge cable technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of low construction efficiency and high construction risk, and achieve the effects of improving construction efficiency, reducing equipment weight, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

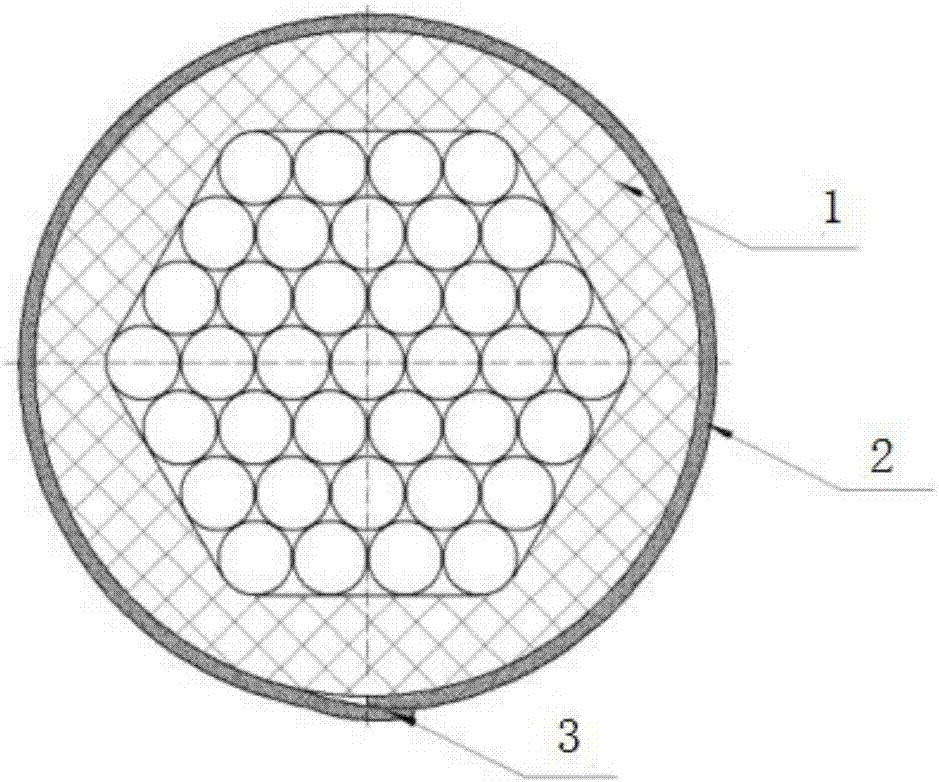

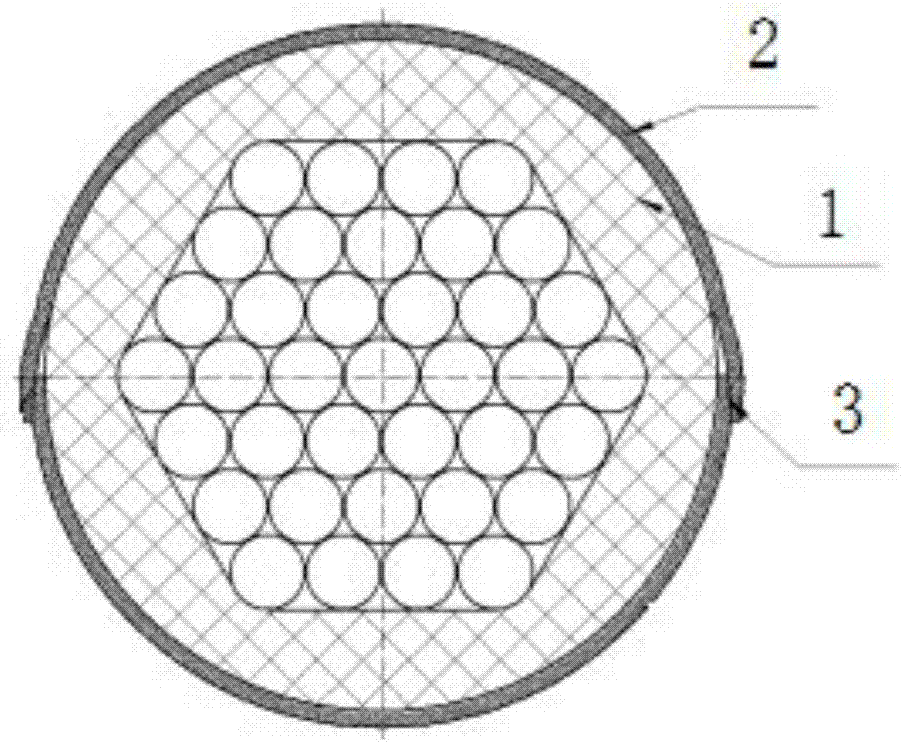

[0020] Attached below Figure 1-3 The present invention will be described in detail.

[0021] Such as figure 1 As shown, the present invention provides a method for covering the cable body with PVF film. The length of the PVF film matches the length of the cable body, and the wide edge of the PVF film is coated along the circumference of the cable body. This method utilizes the self-adhesiveness of the PVF film to be better than the adhesion to the cable body to ensure that the PVF film will not fall off from the cable body; at the same time, the length of the PVF film is customized according to the length of the cable body, and the winding film disc does not need to be rotated , so the size of the stretch film disc is not affected. This avoids multiple replacements of the stretch film discs.

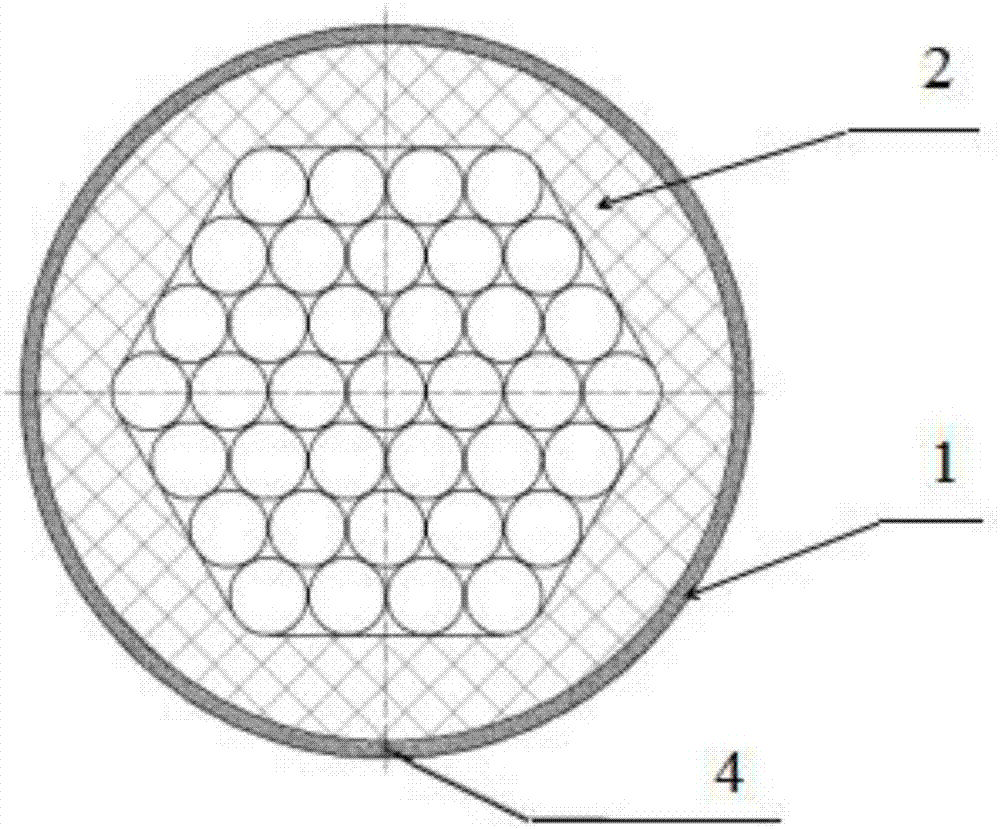

[0022] Such as figure 2 As shown, the present invention provides a kind of method that PVF film coats the cable body, adopts a plate of PVF film (2) to coat the cable body (1), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com