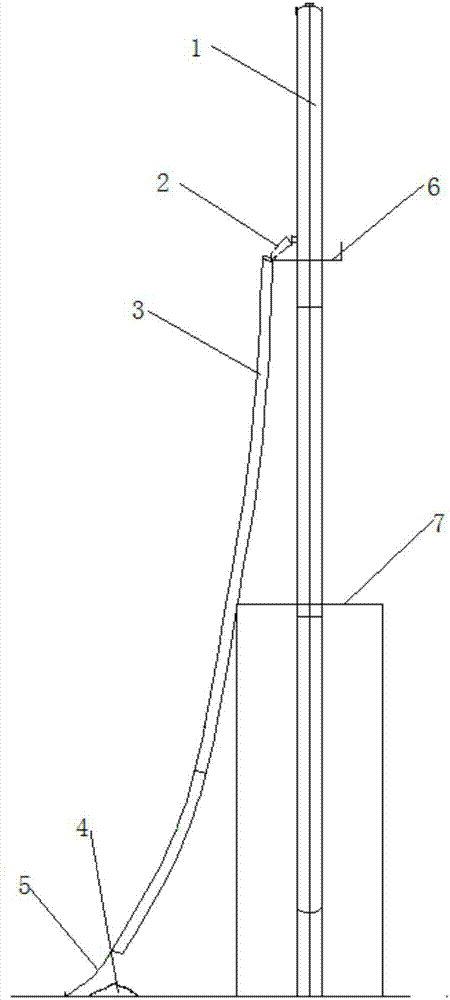

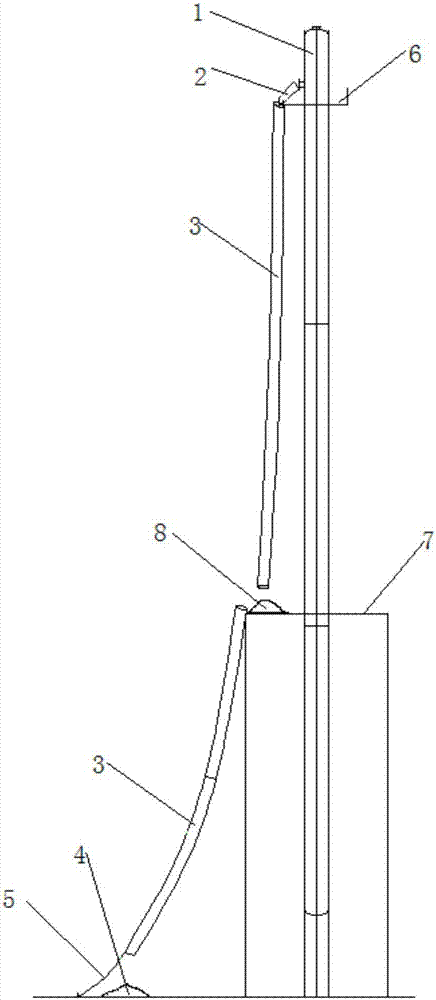

Slide-way-type unloading and filling construction method

A construction method and slideway-type technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of affecting the progress of the maintenance period, consuming manpower and material resources, and occupying the maintenance period, so as to achieve convenient disassembly, folding and recycling, and increase the cost , Efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

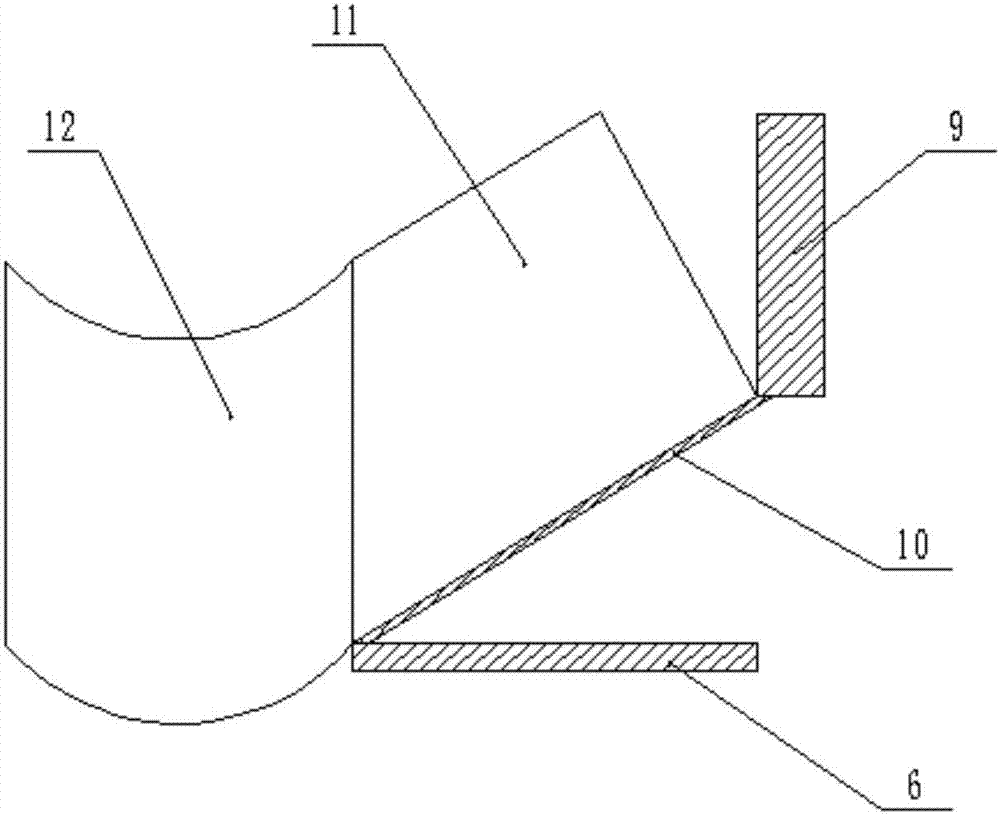

Method used

Image

Examples

Embodiment

[0067] Estimation of economic benefits: The amount of removal of random packing in this project is about 290 tons.

[0068] If the traditional construction method is adopted, the worker fills the woven bag, and the hoist transports it up and down. It is estimated that it will take 300 man-days of labor and 30 shifts of 3t winches. The total cost is 300*200+30*50=61500.

[0069] If the construction method of unloading filler by slideway is used, it is estimated that 150 man-days will be required, and the cost of the slideway is 10,000 yuan. The total cost is 150*200+10000=40000 yuan.

[0070] In summary, the project saves 21,500 yuan of funds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com