A device and method for simulating the impact of fire disturbance on groundwater in terrestrial ecosystems

An ecosystem and simulation device technology, applied in the field of pollution environment ecology, can solve problems such as difficult monitoring, difficult groundwater sampling and direct analysis process, complex geological conditions of ecosystems, vegetation coverage, hydrothermal conditions, etc., to achieve Wide application range, high precision and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

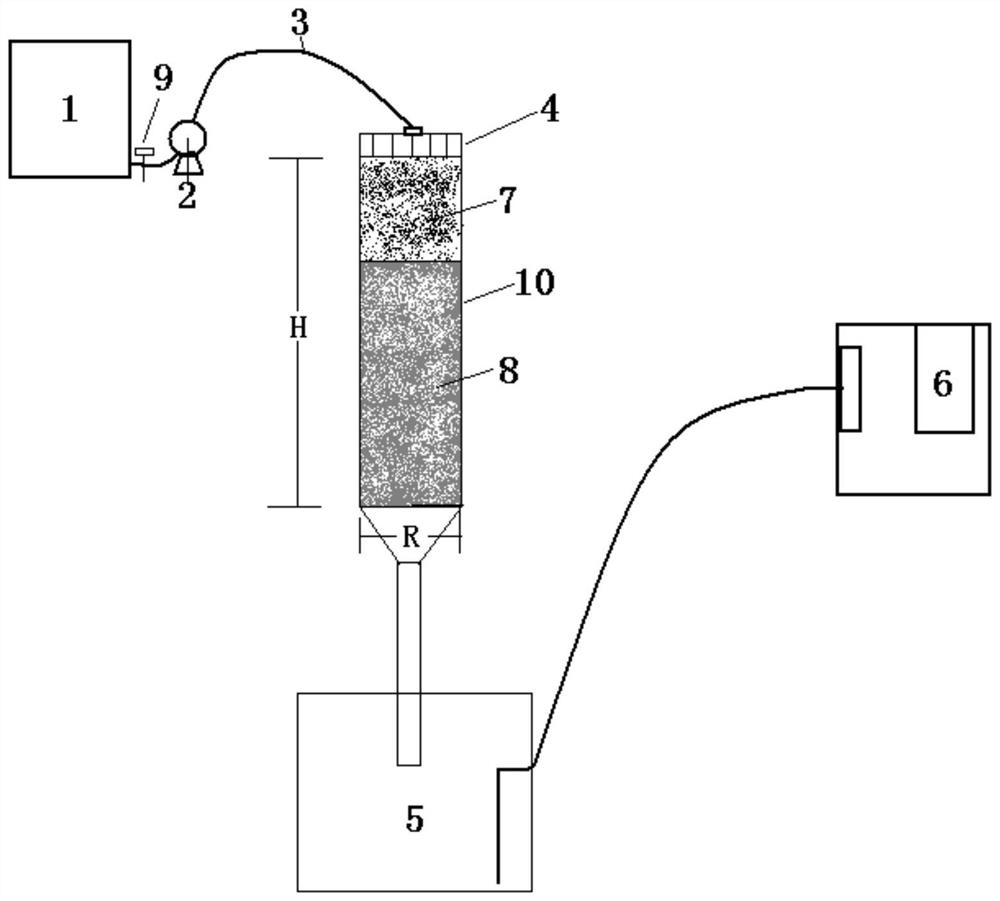

Method used

Image

Examples

example 1

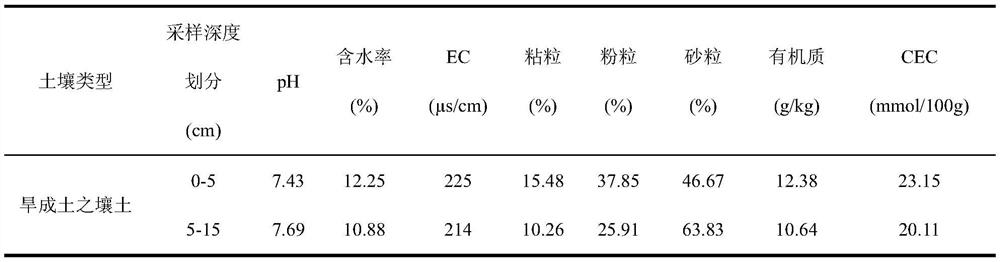

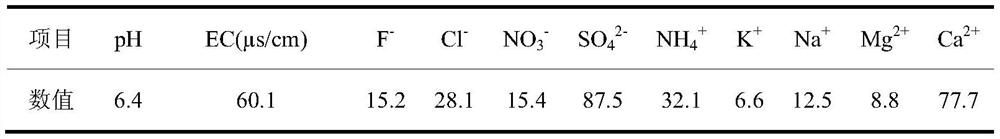

[0041] In the first step, the undisturbed soil column collected by the soil auger is divided into two parts (the inner wall of the soil auger has a cylindrical plug casing with a diameter of 5 cm and a length of 15 cm), namely 0-5 cm topsoil and 5-15 cm middle soil. The two-layer soil samples are naturally air-dried and passed through a 2mm sieve to remove impurities such as plant residues and oversized stone particles; the 0-5cm soil samples after sieving are subjected to heat treatment to simulate the soil surface biochar and burnt soil formed by natural fire interference , the heating device is a muffle furnace, and the specific heating process is: heating at 100°C for 2 hours, then raising the temperature to 250°C for 2 hours, and cooling to obtain fire-disturbed biochar and fire-burned soil, namely fire-disturbed simulated soil 7.

[0042] In the second step, the upper layer of the leaching column with a height of 15 cm and a diameter of 5 cm is filled with fire interferen...

example 2

[0052] In the first step, the undisturbed soil column collected by the soil auger is divided into two parts (the inner wall of the soil auger has a cylindrical plug casing with a diameter of 5 cm and a length of 15 cm), namely 0-5 cm topsoil and 5-15 cm middle soil. The two-layer soil samples are naturally air-dried and passed through a 1mm sieve to remove impurities such as plant residues and oversized stones; the 0-5cm soil samples after sieving are subjected to heat treatment to simulate the soil surface biochar and burnt soil formed by natural fire interference , the heating device is a muffle furnace, and the specific heating process is: heating at 150°C for 3 hours, then raising the temperature to 300°C for 4 hours, and then obtaining fire interference biochar and fire soil after cooling, that is, fire interference simulation soil 7.

[0053] In the second step, the upper layer of the leaching column with a height of 15 cm and a diameter of 5 cm is filled with 5 cm thick ...

example 3

[0064] In the first step, the undisturbed soil column collected by the soil auger is divided into two parts (the inner wall of the soil auger has a cylindrical plug casing with a diameter of 5 cm and a length of 15 cm), namely 0-5 cm topsoil and 5-15 cm middle soil. The two-layer soil samples are naturally air-dried and passed through a 4mm sieve to remove impurities such as plant residues and oversized stone particles; the 0-5cm soil samples after sieving are subjected to heat treatment to simulate the soil surface biochar and burnt soil formed by natural fire interference , the heating device is a muffle furnace, and the specific heating process is: heating at 200°C for 4 hours, then raising the temperature to 350°C for 3 hours, and then obtaining fire-disturbed biochar and fire-burned soil after cooling, that is, fire-disturbed simulated soil 7.

[0065] In the second step, the upper layer of the leaching column with a height of 15 cm and a diameter of 5 cm is filled with 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com