Part sliding guiding device with detection function

A slide-off guide and parts technology, applied in the field of parts slide-off guide device, can solve the problems of no automatic detection function, low part conveying efficiency, high labor intensity of workers, etc., and achieve the effects of low cost, high detection efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

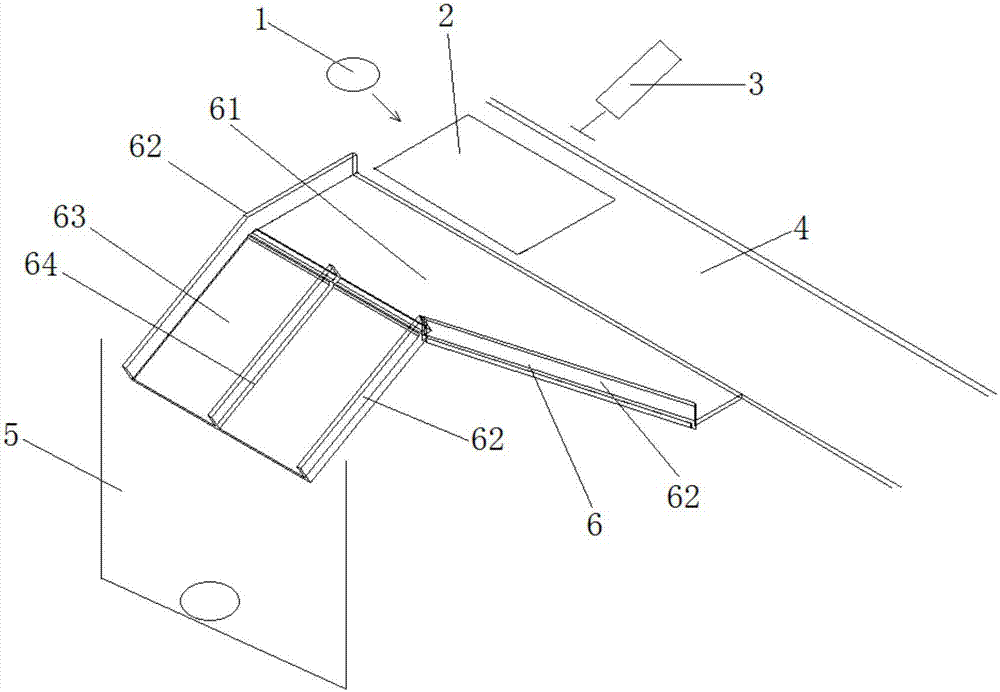

[0022] A part slipping guide device with detection function, such as figure 1 As shown, it includes a transmission channel 4, a sliding guide plate 6, a gravity detection unit 2 and a sorting unit 3. The transmission channel 4 is provided with a conveyor belt for conveying parts 1, and the sliding guide plate 6 is arranged on the side of the transmission channel 4. The gravity detection The unit 2 is arranged on the transmission channel 4 and is located at the entrance of the slide guide plate 6, the sorting unit 3 is arranged on the opposite side of the slide guide plate 6, the gravity detection unit 2 and the sorting unit 3 are connected by a controller, and the sorting unit 3 A pusher is provided to push the parts 1 that have passed the detection by the gravity detection unit 2 to the sliding guide plate 6 and fall into the turnover box 5 located at the lower part of the sliding guide plate 6 .

[0023] Specifically, the sliding guide plate 6 includes a connecting base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com