Motorbike aluminum ring punching machine

A technology of motorcycles and punching machines, which is applied in the direction of perforating tools, bicycle accessories, metal processing equipment, etc., can solve the problems of low work efficiency and incomplete and continuous production process, and achieve the effect of low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

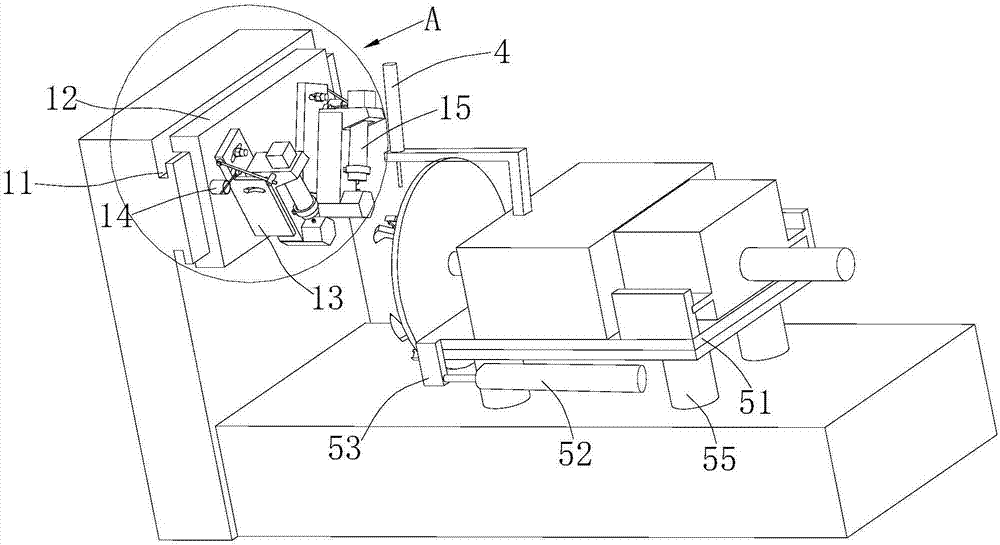

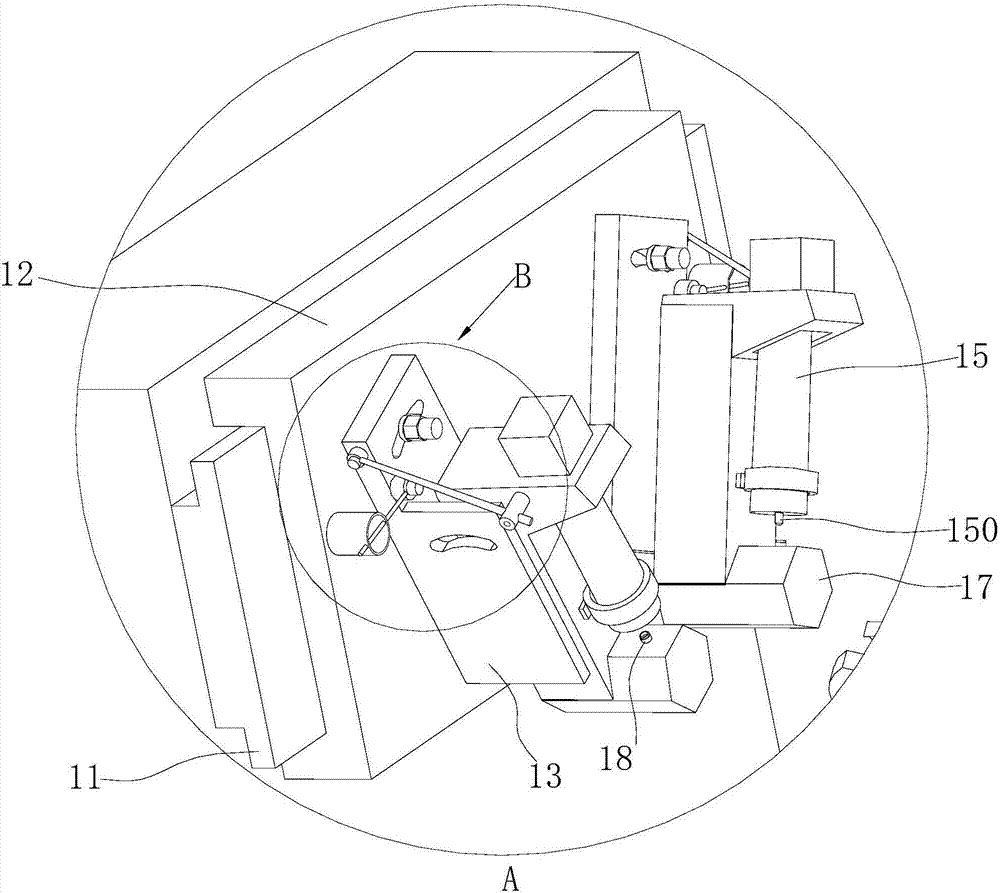

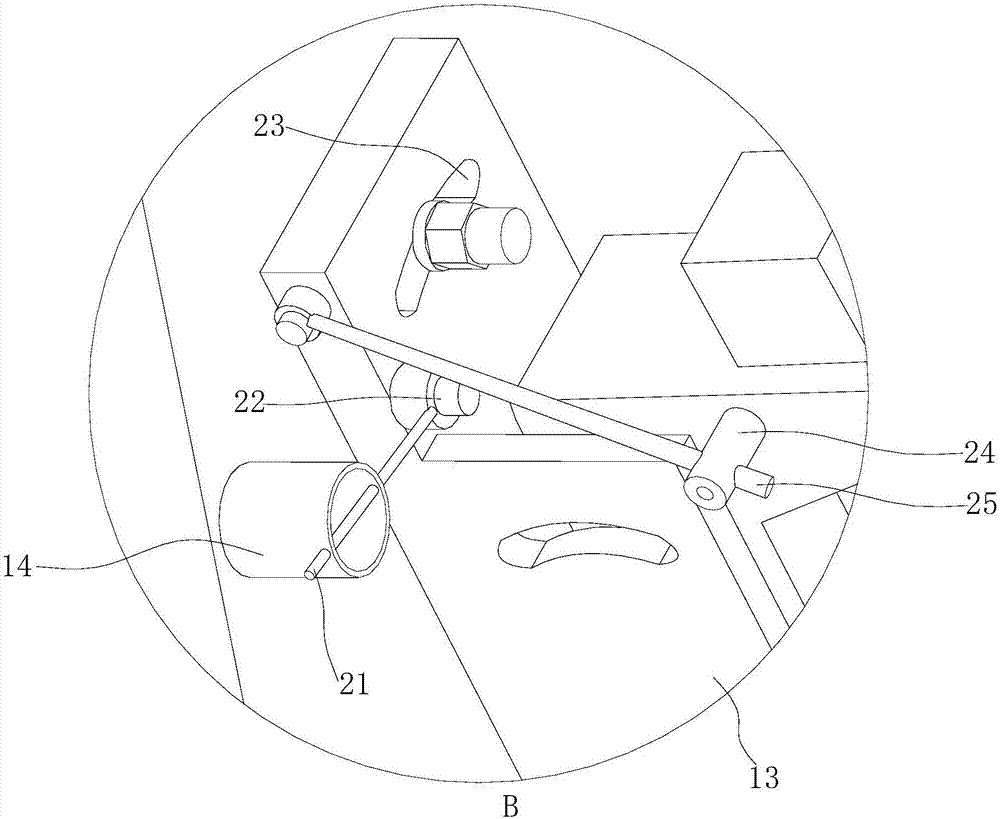

[0026] This embodiment provides a technical solution:

[0027] like Figure 1-7 As shown, a motorcycle aluminum ring punching machine includes a body, which is characterized in that the body is provided with: an aluminum ring clamping device for fixing and clamping a motorcycle aluminum ring; an aluminum ring vortex pressing device for The vortex is punched on the ring surface to form a vortex; the aluminum ring clamping device includes the claw 32 for clamping the aluminum ring of the motorcycle, the turntable for slidingly installing the claw 32, the driving mechanism for driving the turntable to rotate in equal parts, and the adjustment The distance between the jaws 32 is used to clamp the tightness adjustment mechanism of the aluminum ring of the motorcycle; the aluminum ring vortex pressing device includes two mirror images and is used for punching on the aluminum ring surface. The fixed seat 13 of the mechanism 15, the drilling part of the aluminum ring is cushioned so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com