Bearing press fitting machine equipment having high automation efficiency

A press-fitting and high-efficiency technology, applied in the field of press-fitting machinery, can solve problems such as low work efficiency, poor automation ability, inability to work intelligently and consistently, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

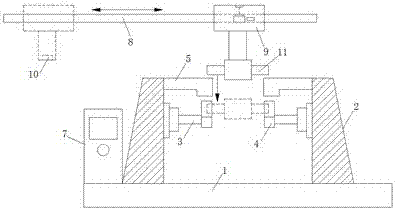

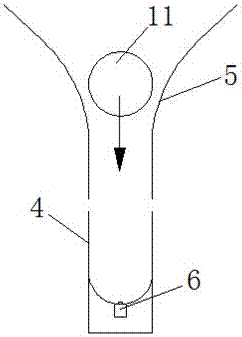

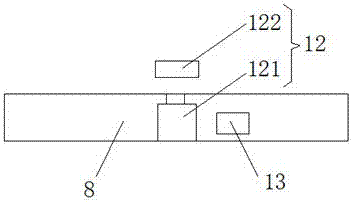

[0017] Reference Figure 1-3 , A bearing press equipment with high automation efficiency, including placement platform 1, mounting pillar 2, hydraulic press arm 3, bearing receiving fixture 4, drop guide rail 5, micro pressure switch 6, controller 7, horizontal guide rail 8 , The electric movable seat 9, the electromagnetic adsorption structure 10, the motor shaft 11, the position sensing device 12, the NFC near-field recognition module 121, the NFC chip 122 and the brake controller 13. The upper surface of the platform 1 is mounted on both sides vertically Mounting pillar 2, the inner side of the middle of the mounting pillar 2 is horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com