A kind of outdoor weather-resistant engineering material based on fast-growing grass and its preparation method

A technology of engineering materials and fast-growing grasses, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., to achieve strong weather resistance, fine wood, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

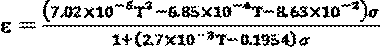

Method used

Image

Examples

Embodiment 1

[0031] An outdoor weather-resistant engineering material based on fast-growing grasses, the outdoor weather-resistant engineering material is an alternating layered structure, and the layered structure is 3 layers, including odd-numbered layers and even-numbered layers, and the odd-numbered layers are pennisetum. The even-numbered layers include polylactic acid wood wool and wood composite particles, and by weight percentage, the polylactic acid wood wool includes: wheat straw powder 20%, polylactic acid 80%; the wood composite particles include: high-density polyethylene (HDPE ) 50%, wheat straw powder 40%, stearic acid 7%, ethylene-vinyl acetate copolymer (EVA) 3%; the outdoor weather-resistant engineering materials are rolled, pulverized, pre-compounded, paved, and three-dimensional thermoformed Composite made of five processes.

[0032] A kind of outdoor weather-resistant engineering material preparation method based on fast-growing grass, comprises the steps:

[0033] 1)...

Embodiment 2

[0039]An outdoor weather-resistant engineering material based on fast-growing grass, the outdoor weather-resistant engineering material is an alternate layered structure, the layered structure is 11 layers, including odd-numbered layers and even-numbered layers, the odd-numbered layers are pennisetum, and the The even-numbered layers include polylactic acid wood wool and wood composite particles, and by weight percentage, the polylactic acid wood wool includes: wheat straw powder 30%, polylactic acid 70%; the wood composite particles include: high-density polyethylene (HDPE ) 55%, wheat straw powder 35%, stearic acid 5%, ethylene-vinyl acetate copolymer (EVA) 5%; the outdoor weather-resistant engineering materials are rolled, pulverized, pre-compounded, paved, and three-dimensional thermoformed Composite made of five processes.

[0040] A kind of outdoor weather-resistant engineering material preparation method based on fast-growing grass, comprises the steps:

[0041] 1) Fla...

Embodiment 3

[0047] An outdoor weather-resistant engineering material based on fast-growing grass, the outdoor weather-resistant engineering material is an alternate layered structure, the layered structure is 7 layers, including odd-numbered layers and even-numbered layers, the odd-numbered layers are pennisetum, and the The even-numbered layers include polylactic acid wood wool and wood composite particles, and by weight percentage, the polylactic acid wood wool includes: wheat straw powder 25%, polylactic acid 75%; the wood composite particles include: high-density polyethylene (HDPE ) 55%, wheat straw powder 40%, stearic acid 3%, ethylene-vinyl acetate copolymer (EVA) 2%; the outdoor weather-resistant engineering materials are rolled, pulverized, pre-compounded, paved, and three-dimensional thermoformed Composite made of five processes.

[0048] A kind of outdoor weather-resistant engineering material preparation method based on fast-growing grass, comprises the steps:

[0049] 1) Fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com