Diaphragm dividing and cutting machine

A slitter and diaphragm technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve problems such as damage to the diaphragm under tension, and achieve the effect of reducing tension and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

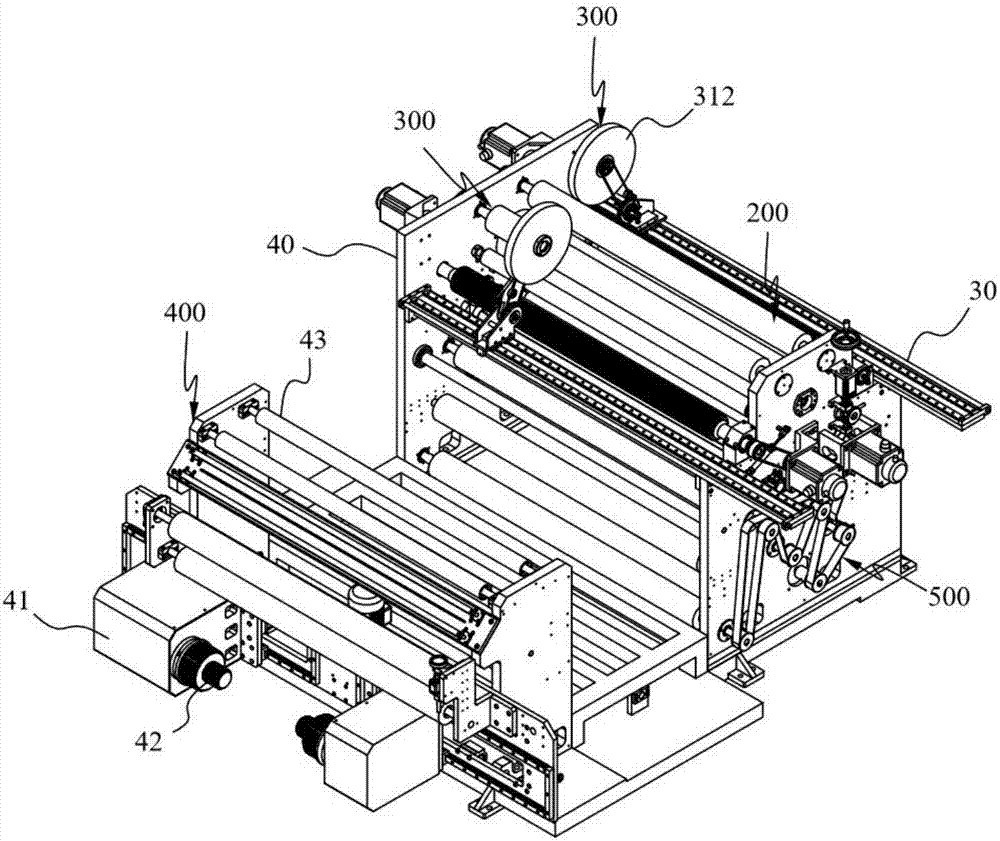

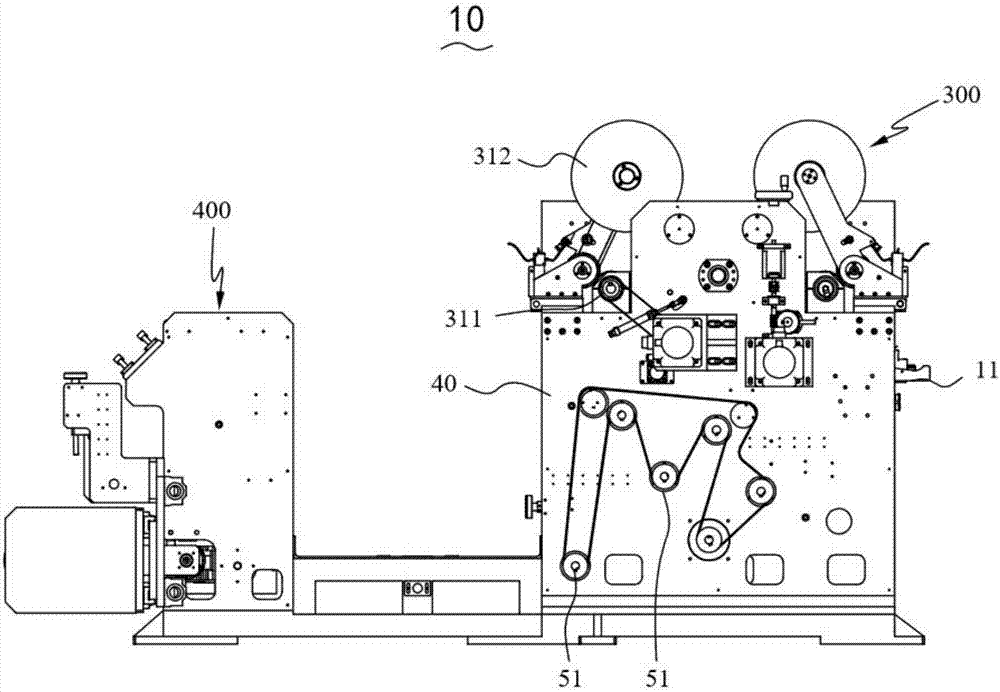

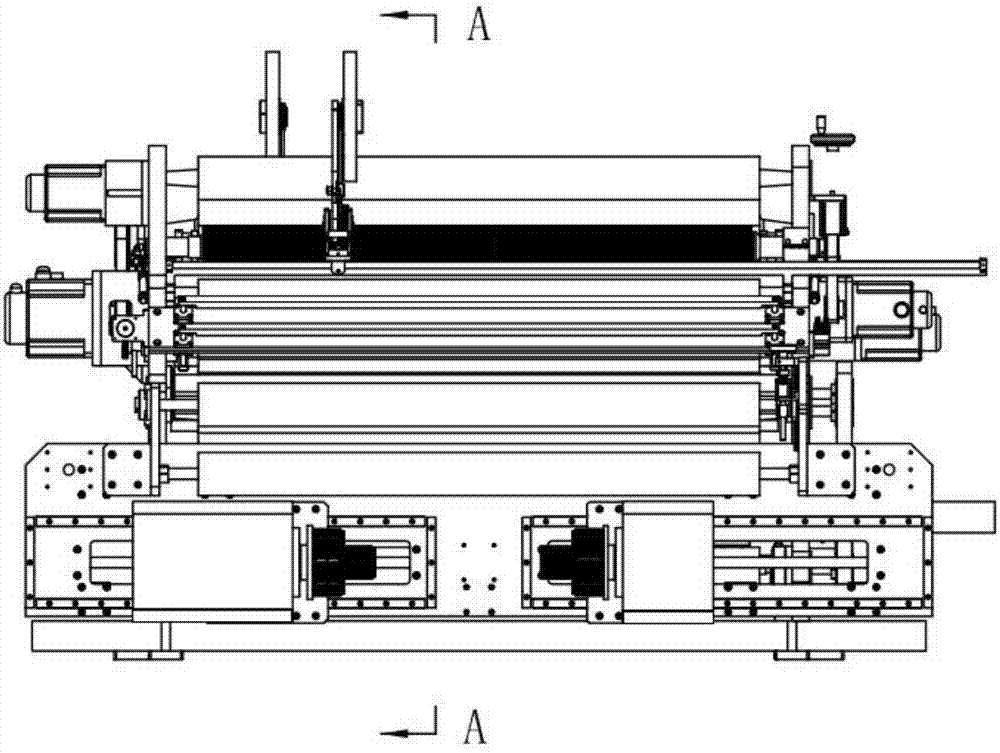

[0044] Please refer to Figure 1 to Figure 7 , the present invention provides a diaphragm slitter 10, the diaphragm slitter 10 includes: a slitting module 100, a separation module 200 and a winding module 300;

[0045] The slitting module 100 receives the diaphragm 20, and cuts the diaphragm 20 so that the diaphragm 20 forms at least two diaphragm belts 21; the separation module 200 is used for actively crimping and conveying the diaphragm 20, and separates the two diaphragm belts 21 for separate output; the winding die The group 300 includes at least two winding devices 31. The winding devices 31 are positioned on the slide rail 30. The two winding devices 31 actively wind up the diaphragm belt 21 respectively. The two winding devices 31 are respectively located on both sides of the separation module 200. The winding device 31 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com