Production method of PUR glue

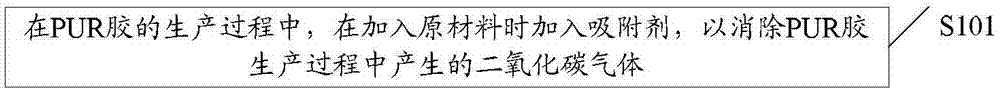

A production method and a complete production technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve problems such as adverse effects on appearance quality, appearance problems of PUR glue, etc., to improve appearance quality, reduce material costs and manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0033] In the following description, use of suffixes such as 'module', 'part' or 'unit' for denoting elements is only for facilitating description of the present invention and has no specific meaning by itself. Therefore, 'module', 'part' or 'unit' may be used in combination.

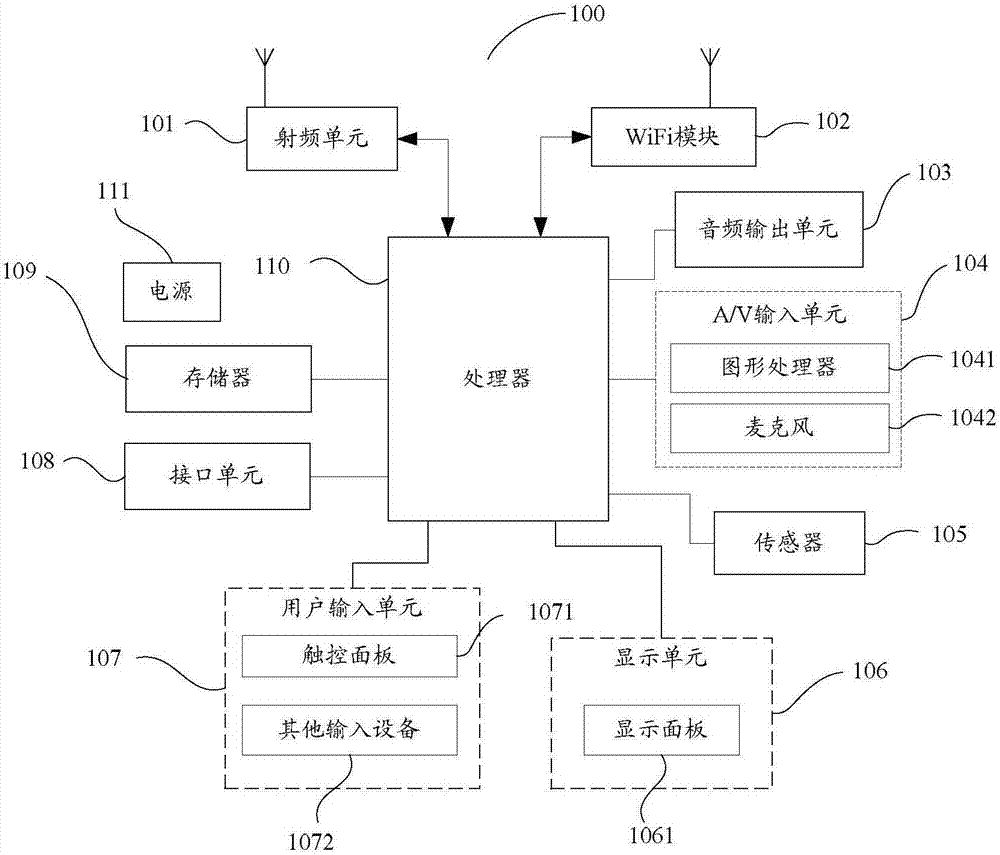

[0034] Terminals may be implemented in various forms. For example, the terminals described in the present invention may include mobile phones, tablet computers, notebook computers, palmtop computers, personal digital assistants (Personal Digital Assistant, PDA), portable media players (Portable Media Player, PMP), navigation devices, portable Mobile terminals such as wearable devices, smart bracelets, and pedometers, and fixed terminals such as digital TVs and desktop computers.

[0035] In the following description, a mobile terminal will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com