Staggered lap-joint structure and method for full framing

It is a technology of full house support and frame, which is used in the erection/assembly of bridges, bridges, buildings, etc. It can solve problems such as high engineering solid structures, and achieve the effect of improving safety factor, enhancing bearing capacity and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

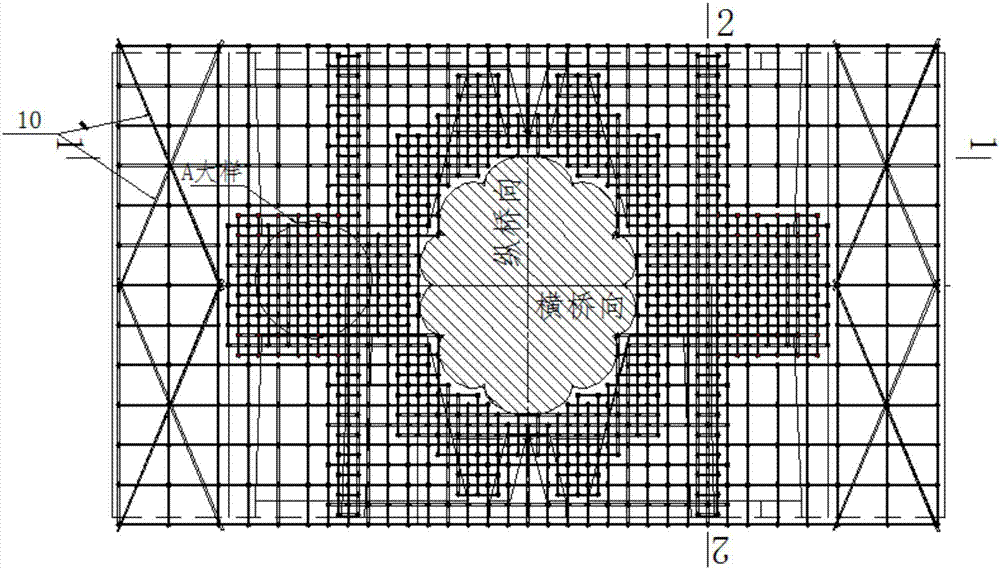

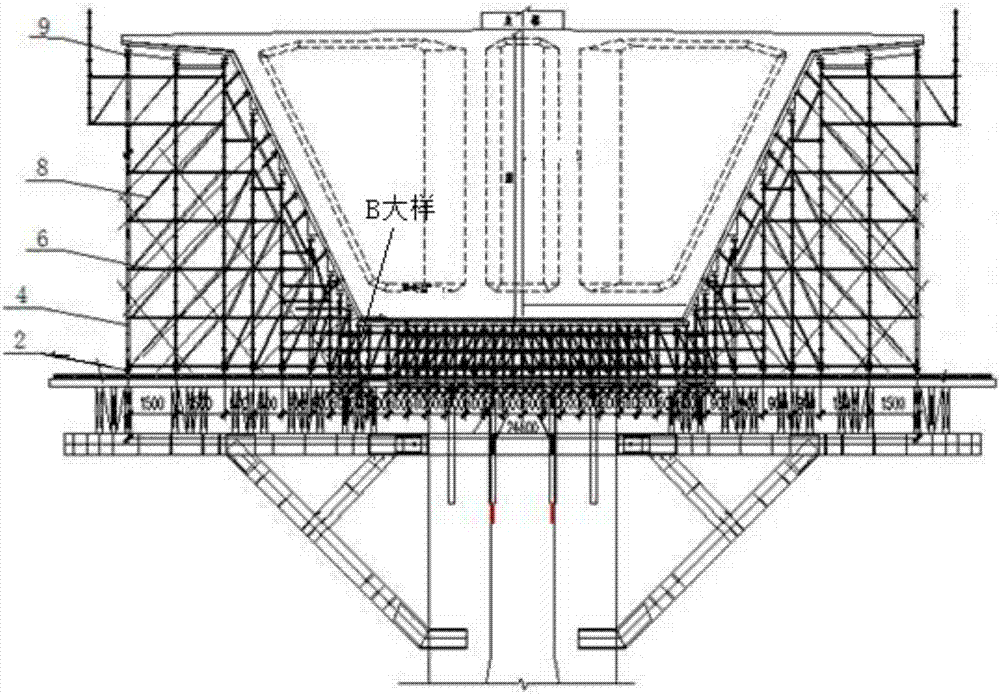

[0032] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

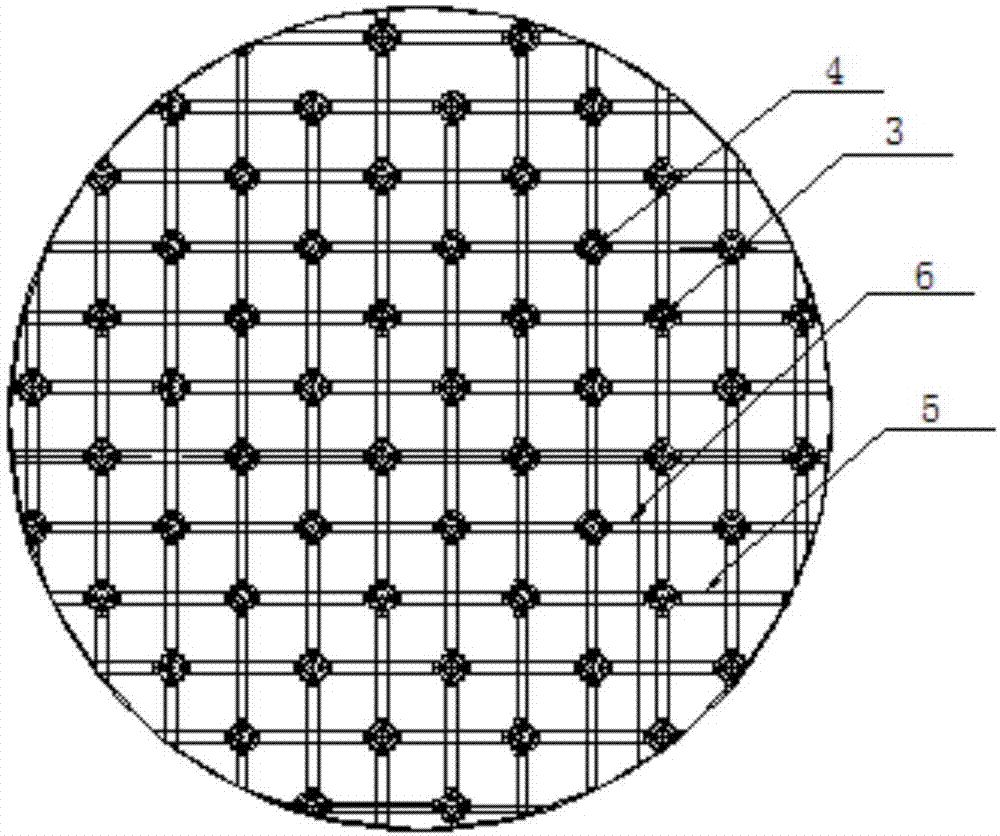

[0033] refer to Figure 1 to Figure 6 As shown, the embodiment of the present invention is a misplaced nesting structure of a full hall support. The full hall support includes a plurality of parallel vertical rods 3 and a plurality of mutually parallel horizontal rods 5, and each vertical rod 3 is perpendicular to each horizontal rod 5. , each vertical bar 3 and each horizontal bar 5 are provided with fasteners for connection and fixation, wherein two adjacent vertical bars 3 and horizontal bars 5 form a rectangular frame unit, and two adjacent vertical bars 3 The opposite corners are connected with vertical slanting bars 7 by fasteners.

[0034] A dislocation vertical rod 4 is arranged at the center of each rectangular frame unit composed of a vertical rod 3 and a horizontal rod 5, and adjacent dislocation vertical rods 4 are connected by a dislocation horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com