Whole roof system synchronous jacking method

A synchronous jacking and integral technology, applied in building maintenance, construction, building construction, etc., can solve the problems of demolition and reconstruction, poor safety, waste of resources, etc., to ensure effective support, ensure no damage, and reduce construction waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

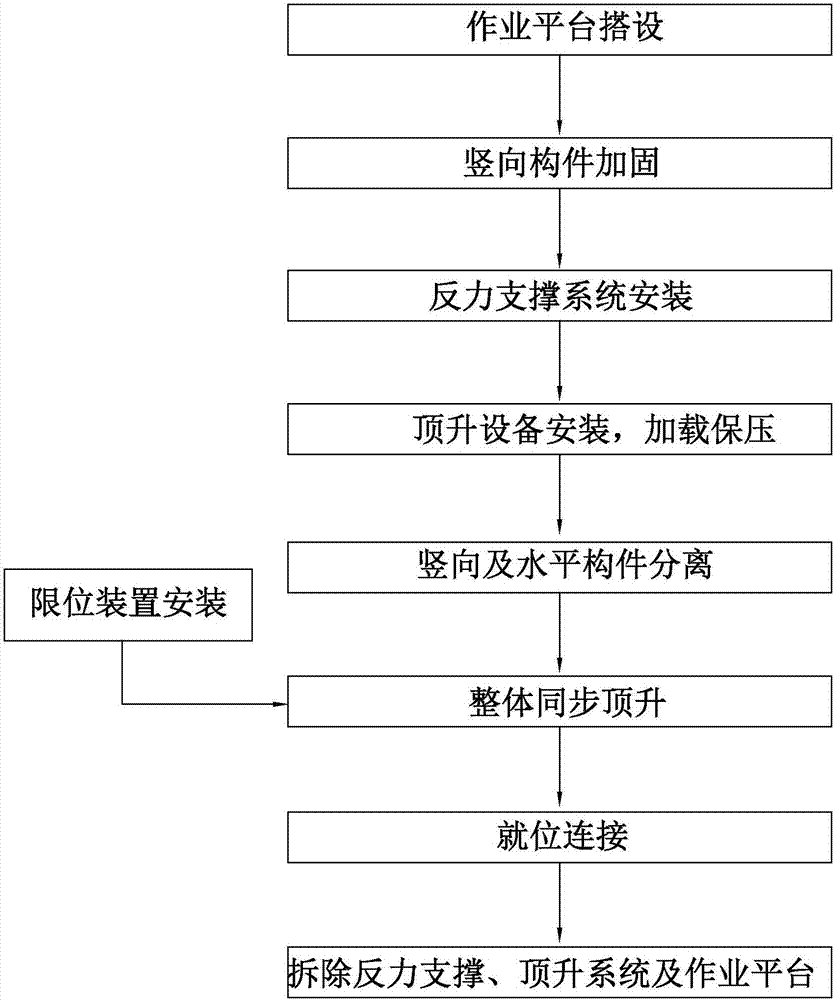

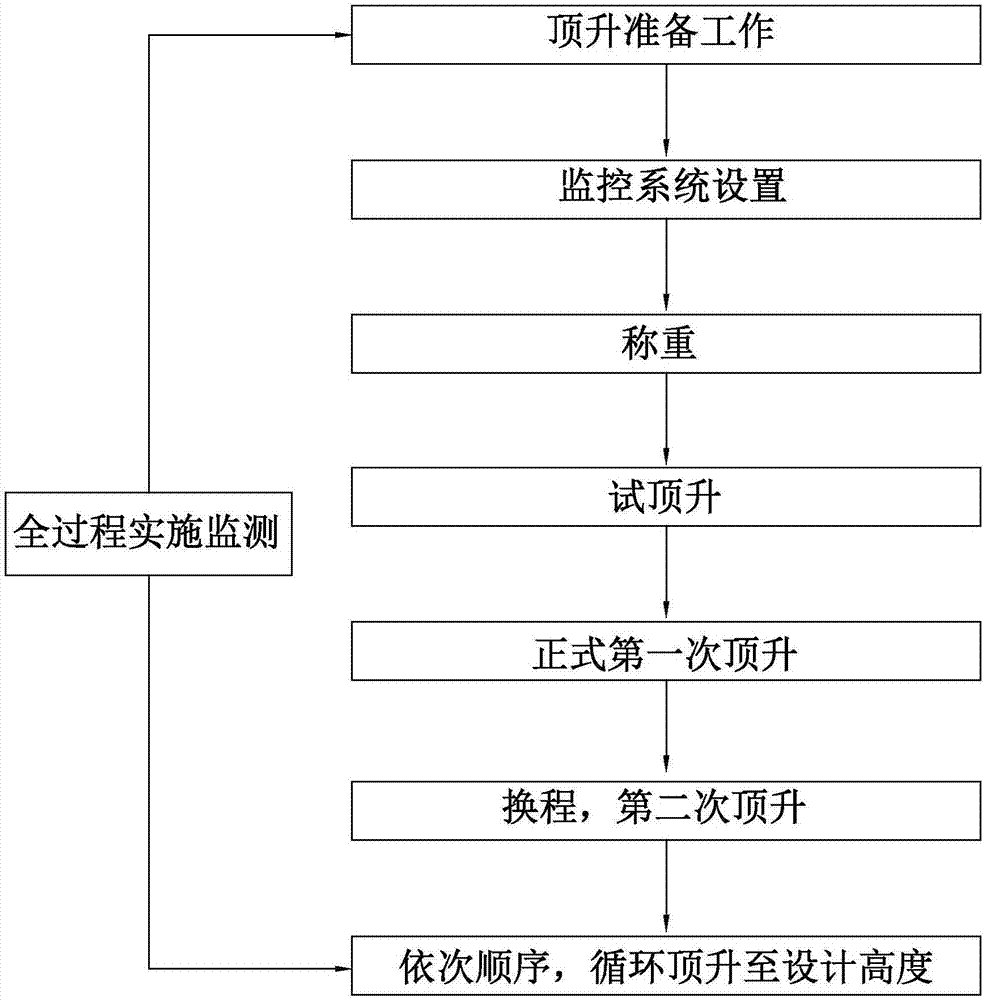

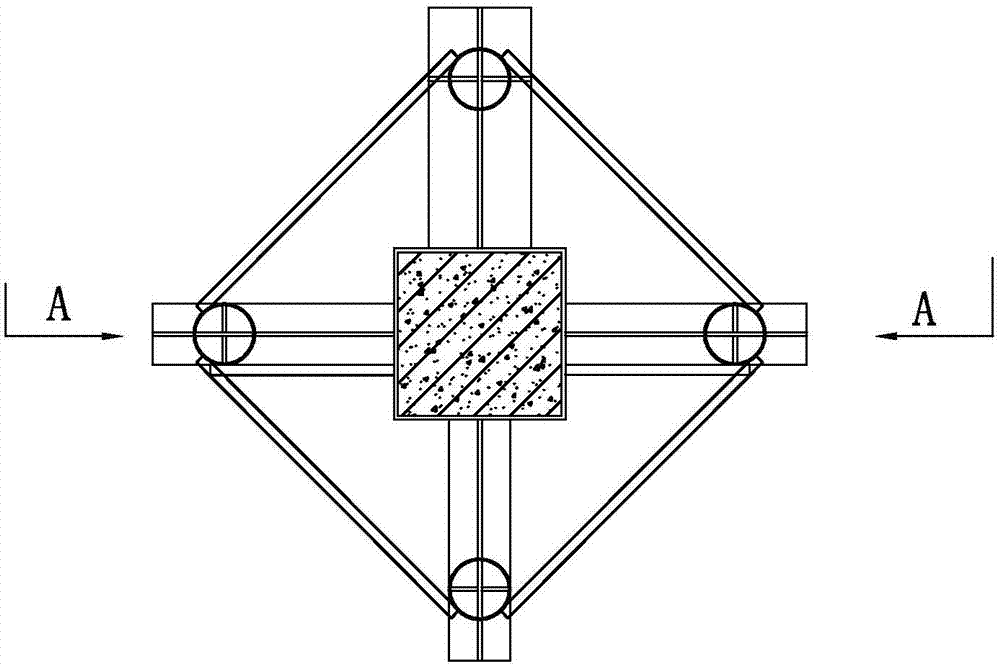

[0036] Embodiment: a synchronous jacking method for an integral roof, setting a reaction support on the existing vertical member, setting a hydraulic jack between the reaction support and the roof frame column, and cutting the existing vertical member, At the same time, a limit device and a movable two-way tie rod are set, and the overall synchronous jacking is implemented through the PLC synchronous lifting control system. After part of the concrete reaches the design strength, the temporary support is removed, so as to achieve the purpose of increasing the height of the house. The specific operation steps include:

[0037] Step 1: Set up the work platform

[0038] Set up steel pipe scaffolding along the frame columns, the spacing between scaffolding poles is 1000×1000mm, the step distance is 1200~1500mm, and safety nets are hung around.

[0039] Step 2: Reinforcement construction of vertical components

[0040] 1. According to the requirements of the design drawings, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com