Multi-stage self-sequencing liquid-controlled fracturing ball throwing device

A ball-throwing device and fracturing technology, applied in wellbore/well valve device, production fluid, wellbore/well components, etc., can solve the problems of fracturing interval loss, high risk of personnel safety, economic loss, etc. The effect of improving fracturing construction efficiency, reducing safety risks, large-scale projects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

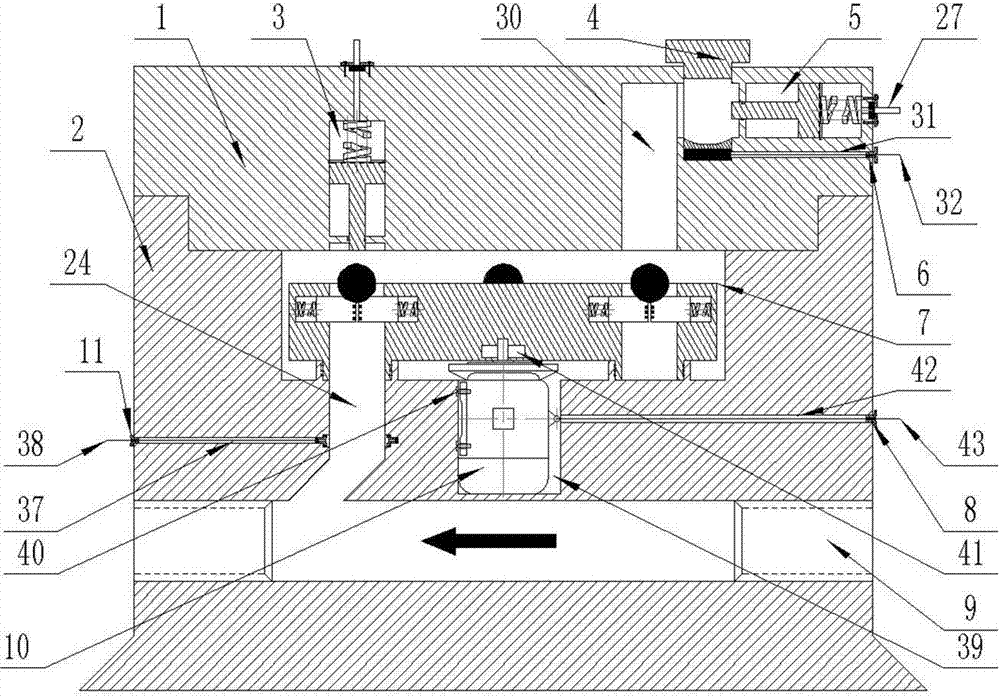

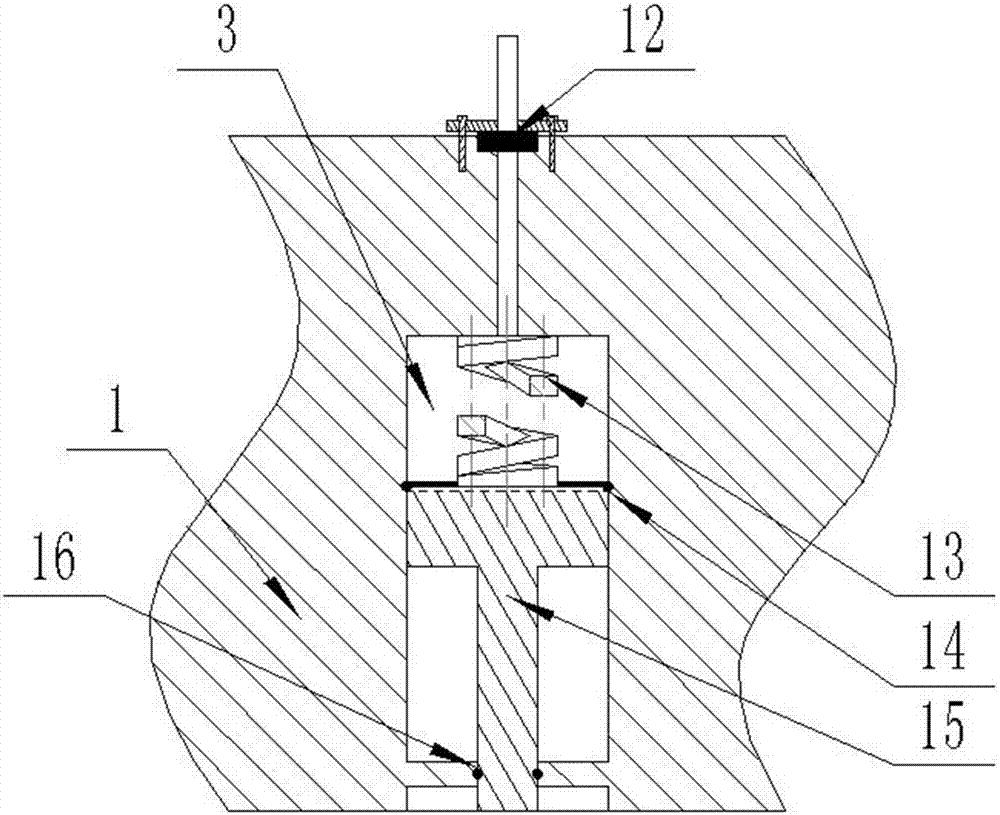

[0029] Such as figure 1 , 4 , 5, a multi-stage self-sorting hydraulic fracturing pitching device provided by the present invention includes a cover plate 1, a base 2, and a turntable 7; the cover plate 1 and the base 2 pass through in a stepped form Threaded connection, the upper part of the base 2 is provided with an accommodation cavity, and the turntable 7 is placed in the accommodation cavity.

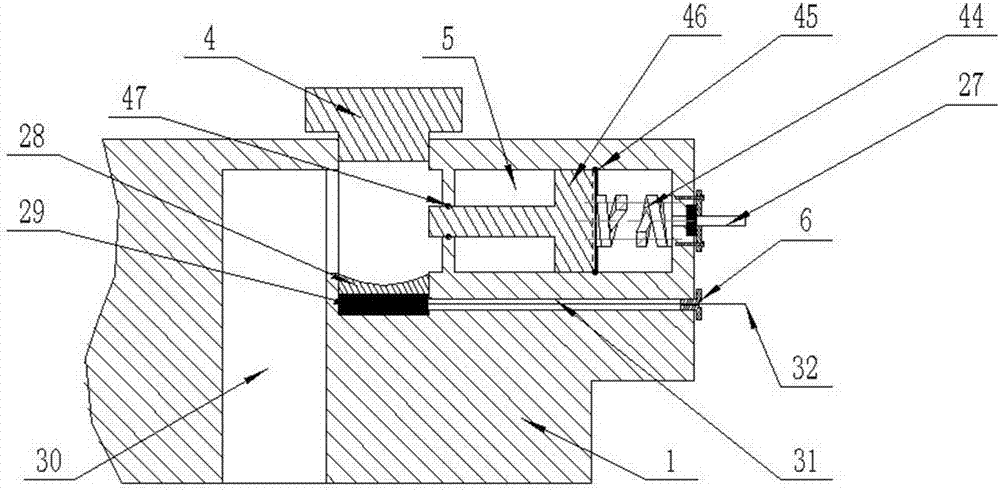

[0030] On the right side of the cover plate 1, there is a chamber for placing fracturing balls, which is sealed by a sealing cover 4, and a concave pad 28 is arranged at the bottom of the chamber for placing fracturing balls. A gravity sensor 29 is arranged on the lower side of the concave cushion block 28. The gravity sensor 29 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com