Fracturing pipe column and a fracturing method

A fracturing string and fracturing technology, applied in the field of oil production and completion of oil and gas wells, can solve problems such as construction interruption, increased workload, and affecting fracturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

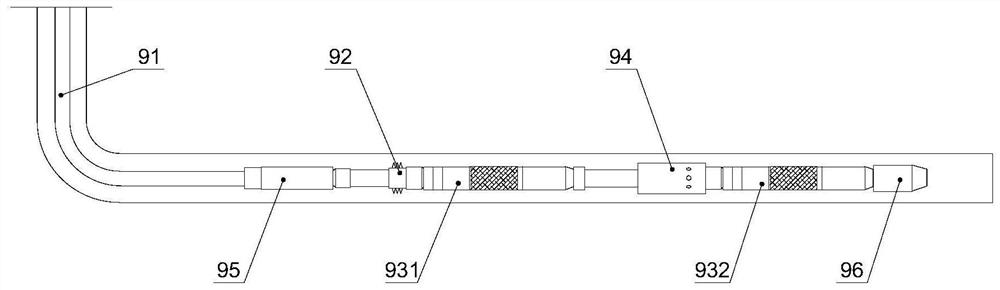

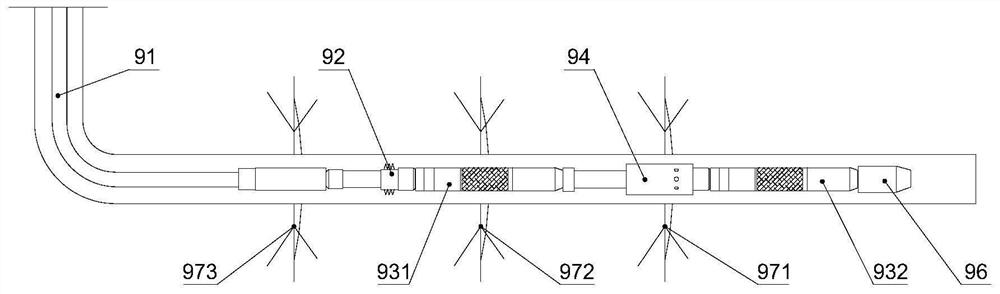

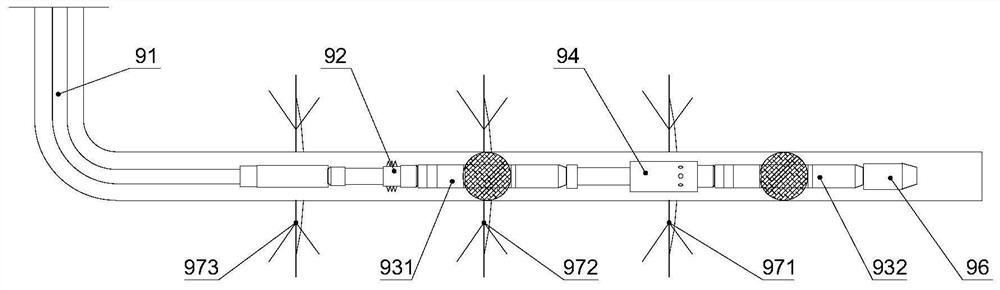

[0063] The invention provides a fracturing string, such as figure 1 As shown, the fracturing string includes a tubing 91, a hydraulic anchor 92, a first packer 931, a differential pressure sleeve 94, and a second packer 932 connected in sequence from top to bottom; Figure 4 with Image 6 As shown, the differential pressure sliding sleeve 94 includes: a sandblasting cylinder 10, a connecting cylinder 20 and a sliding sleeve 30, the side wall of the sandblasting cylinder 10 is provided with a sandblasting port 11; the connecting cylinder 20 is fixedly connected to the upper end of the sandblasting cylinder 10, and connected The lower end of the cylinder 20 is provided with a cylinder connecting portion 203, and the cylinder connecting portion 203 is arranged in the sandblasting cylinder 10; 10, the outer wall of the sliding sleeve 30 is sealed with the inner wall of the sandblasting cylinder 10 and the inner wall of the connecting cylinder 20 respectively. Below, a liquid sto...

Embodiment 2

[0072] The present invention provides a differential pressure sliding sleeve 94, such as Figure 4 with Image 6 as shown, Figure 4 The upper end 71 of the middle differential pressure sliding sleeve is located at Figure 4 The upper end of the differential pressure sliding sleeve 94 includes: a sandblasting cylinder 10, a connecting cylinder 20 and a sliding sleeve 30, and the side wall of the sandblasting cylinder 10 is provided with a sandblasting port 11; The lower end of the cylinder 20 is provided with a cylinder connecting portion 203, and the cylinder connecting portion 203 is arranged in the sandblasting cylinder 10; 10, the outer wall of the sliding sleeve 30 is sealed with the inner wall of the sandblasting cylinder 10 and the inner wall of the connecting cylinder 20 respectively. Below, a liquid storage chamber 40 is provided between the outer shoulder 301 and the cylinder connection part 203, and the side wall of the blasting cylinder 10 is provided with a liq...

Embodiment 3

[0092] The present invention provides a fracturing method, using the above-mentioned fracturing string, such as Figure 11 As shown, the fracturing method includes:

[0093] Step S10, lowering the fracturing string to the target layer to be fractured;

[0094] Step S20, the hydraulic anchor 92 is anchored, and the first packer 931 and the second packer 932 are pressed;

[0095] Step S30, continue pressing to open the differential pressure sliding sleeve 94;

[0096] Step S40, implementing fracturing construction for the target layer to be fractured;

[0097] Step S50, pitching or bidding closes the differential pressure sliding sleeve 94;

[0098] Step S60, releasing the pressure in the pipe or lifting the pipe string to realize the unsealing of the first packer 931 and the second packer 932; the hydraulic anchor 92 is unanchored;

[0099] Step S70, lifting the pipe string to the next target layer to be fractured;

[0100] Step S80, repeating steps S20, S30, S40, S50 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com