A high-pressure manifold device suitable for annular sand fracturing process

A technology for sand fracturing and high pressure manifolds, which is applied to wellbore/well valve devices, wellbore/well components, and production fluids, etc. The increase of land area and other problems can achieve the effect of meeting normal construction requirements, reducing operation risks and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

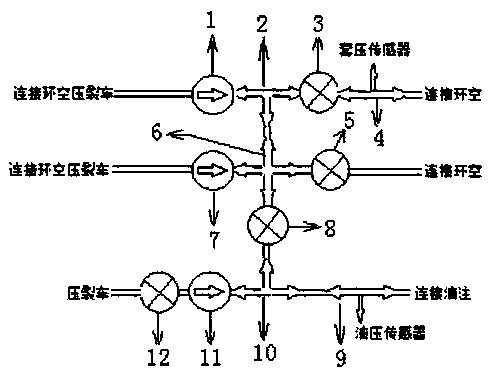

[0020] On the basis of Example 1, the cross 6 is a 3" cross, its structure is F×M×M×M, the buckle type is FIG1502, and the rated working pressure is: 15000PSI. The T-type tee two 4 And the structure of the T-type tee four 9 is the same, both are 3〞×2〞×3〞tee, the structure is F×F×M, the buckle type is FIG 1502, the rated working pressure is: 15000PSI, and the 2〞 interface is connected Pressure sensor. The structure of the check valve one 1, the check valve two 7 and the check valve three 11 is the same, all of which are gate type check valves, the structure is F×M, the buckle type is FIG 1502, and the rated working pressure is : 15000PSI. The structure of the T-type tee-12 and T-type tee-310 is the same, both are 3〞×3〞×3〞tee, the structure is F×F×M, the buckle type is FIG 1502, rated Working pressure: 15000PSI.

[0021] The main performance parameter of device of the present invention:

[0022] Length (mm): about 2000-3000

[0023] Width (mm): about 1500-2000

[0024] Heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com