Pre-lubricating system of engine

A lubrication system and engine technology, applied in the direction of timing lubrication, pressure lubrication of lubrication pumps, etc., can solve the problems of component wear and shorten the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

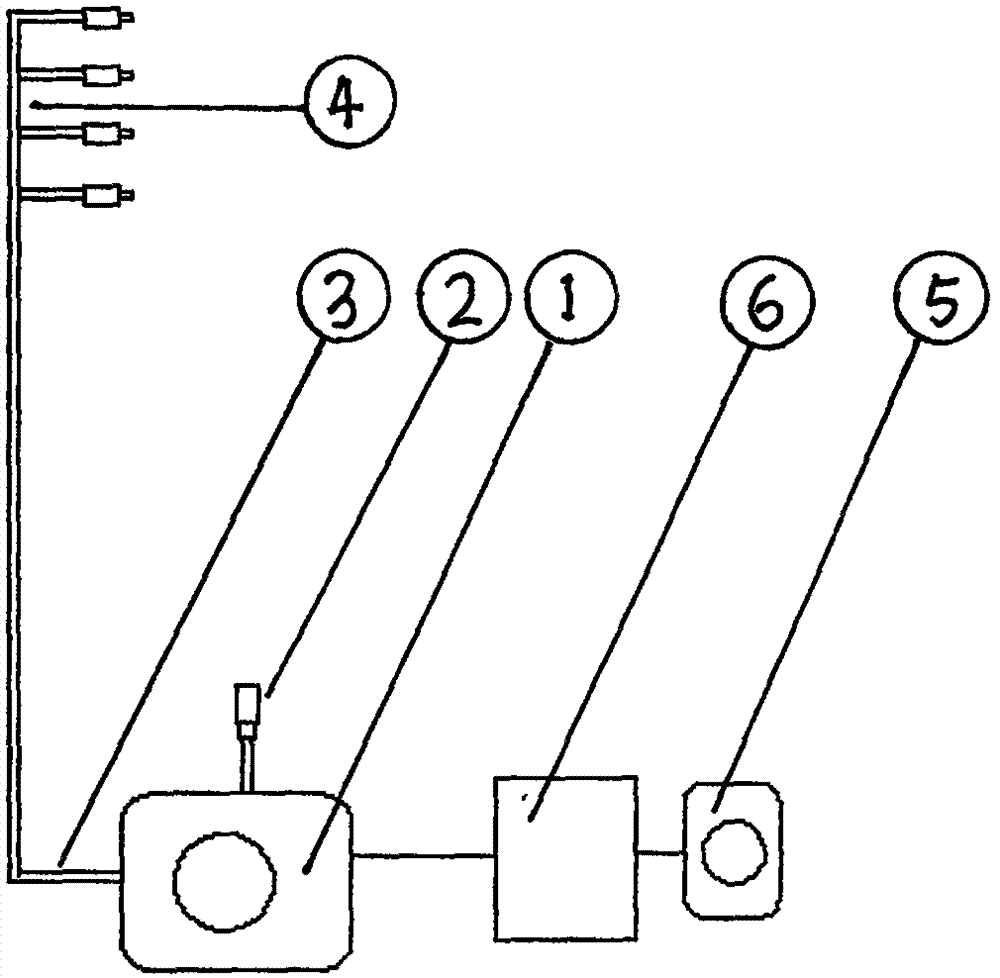

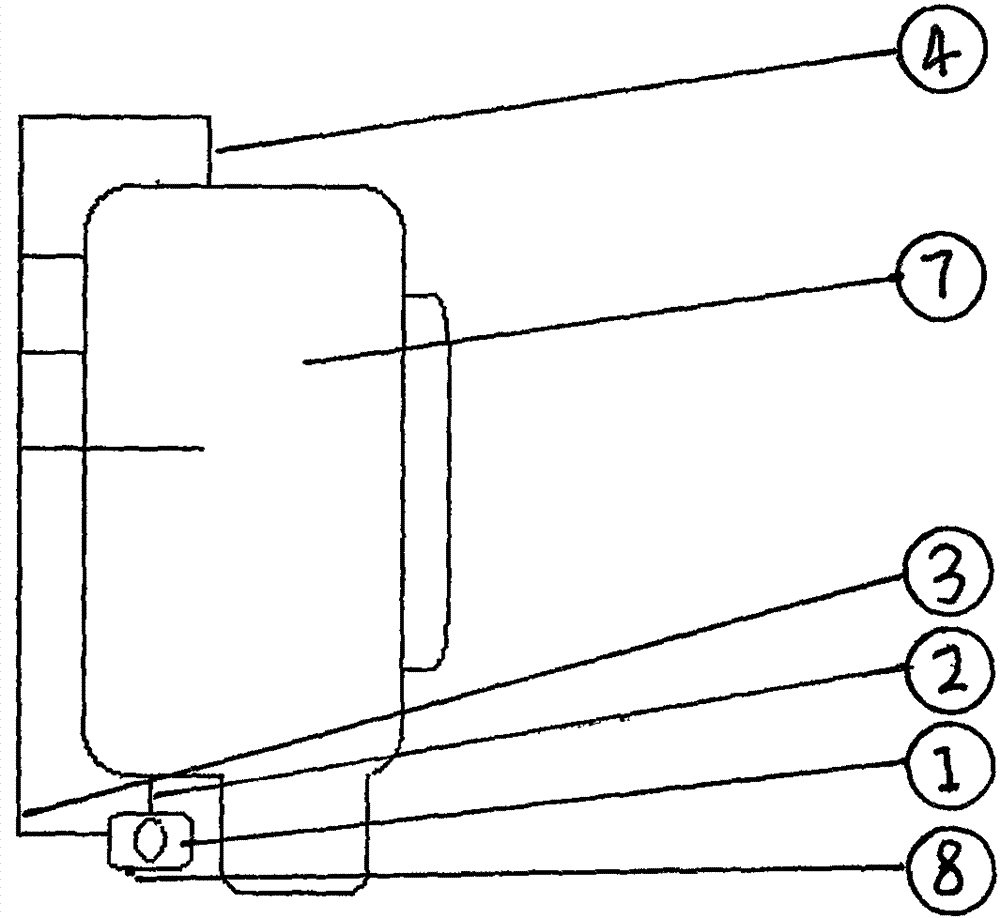

[0007] pass figure 1 It can be seen that the system is composed of an oil pump, a start controller, a start switch and an oil distribution pipeline. The oil well pump (1) is installed at the bottom of the engine, the oil inlet pipe (2) is connected to the oil outlet of the engine, and the oil outlet pipe (3) Connect the oil distribution pipe (4), and the oil well pump (1) is composed of a motor-driven miniature oil pump, which can suck the engine oil inside the engine from the oil inlet pipe (2) during operation, and discharge it into the oil distribution pipe (4) through the oil outlet pipe (3) , the oil distribution pipe is sprayed onto the main parts that are easy to wear inside the engine, and the parts that are not in contact with the oil when the engine is not started are pre-lubricated. The start switch (5) is a human body induction switch, installed in the central control On the platform, when the human body is on the driver's seat, it can be sensed. The start controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com