Adjustable pipe clamp

A technology of pipe clamps and clamp bases, which is applied in the directions of hoses, pipes, pipe supports, etc., can solve the problems of laborious handling, weak installation and fixation of large pipe clamps, and heavy installation bases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

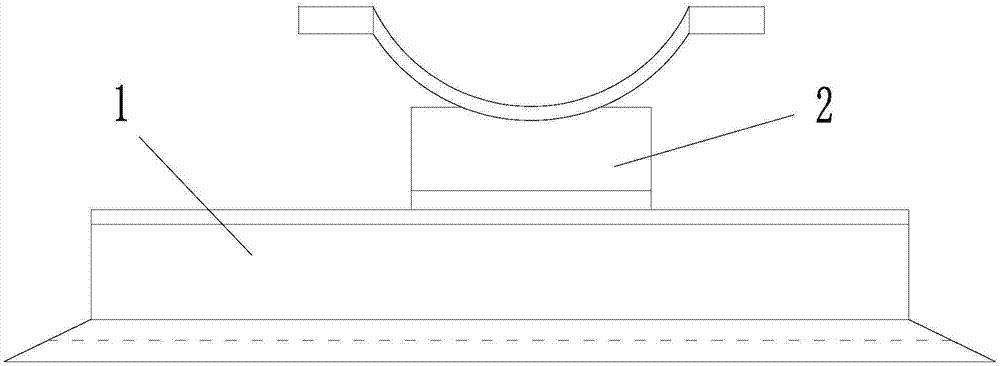

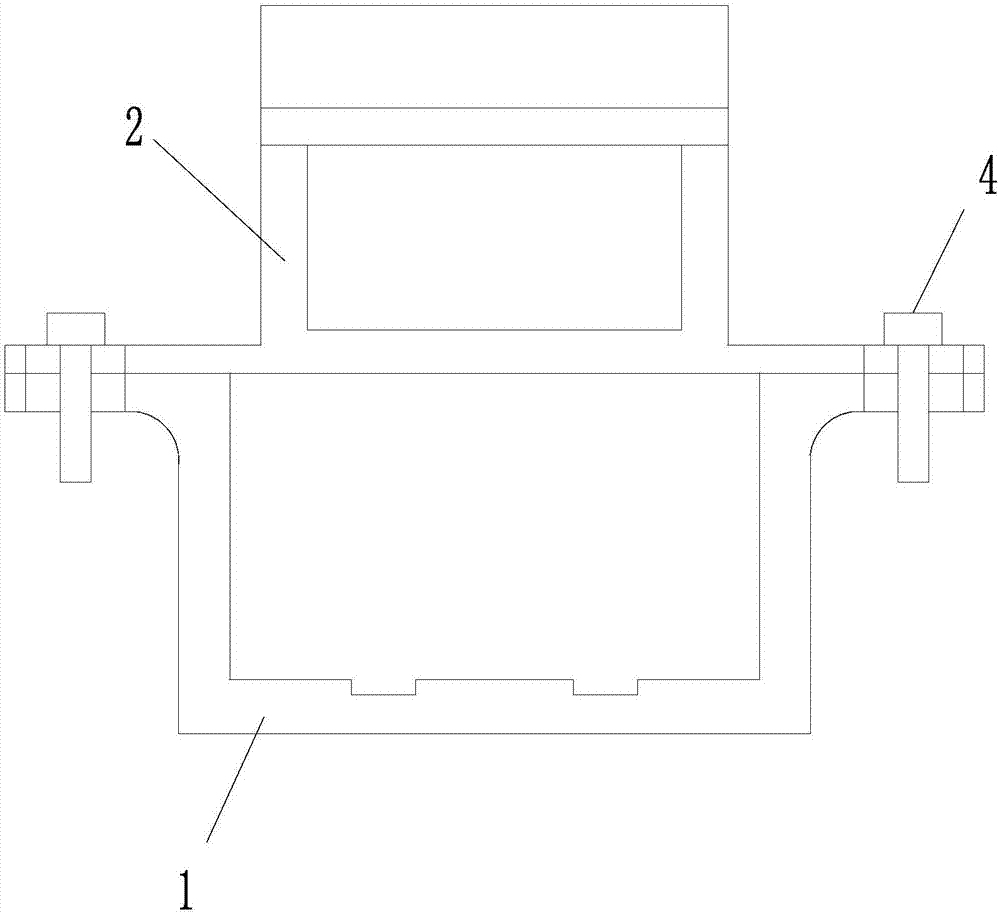

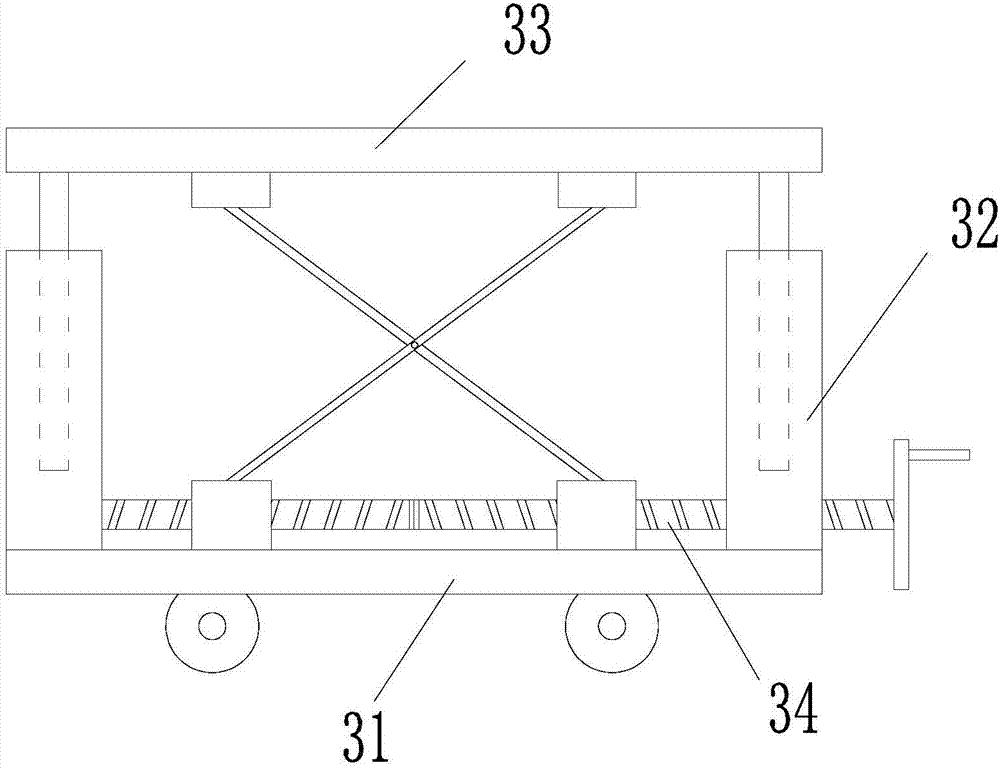

[0021] Such as Figure 1 to Figure 3 As shown, an adjustable pipe clamp includes a mounting seat 1 and a pipe clamp seat 2. An upper pipe clamp and a lower pipe clamp are arranged on the pipe clamp seat 2. The cross section of the mounting seat 1 has a U-shaped structure, and the mounting seat 1 The upper ends of the vertical sides on the left and right sides form a convex horizontal platform; the lower end of the pipe clamp seat 2 rests on the upper ends of the two vertical sides; the front and rear sides of the mounting base 1 are open; the mounting base 1 An in-and-out lift trolley is provided, and the lift trolley includes a top plate 33 that can move up and down.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com