Tube panel arrangement structure for waste heat boiler reheater

A technology for layout structure and waste heat boiler, which is applied in steam superheating, lighting and heating equipment, steam generation, etc., and can solve problems such as large header stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

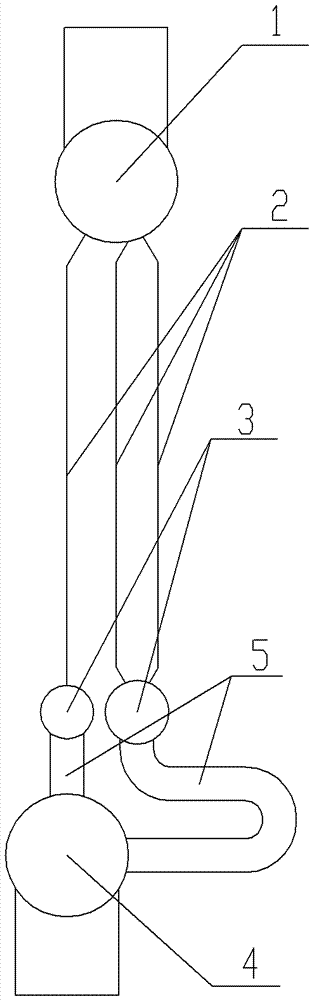

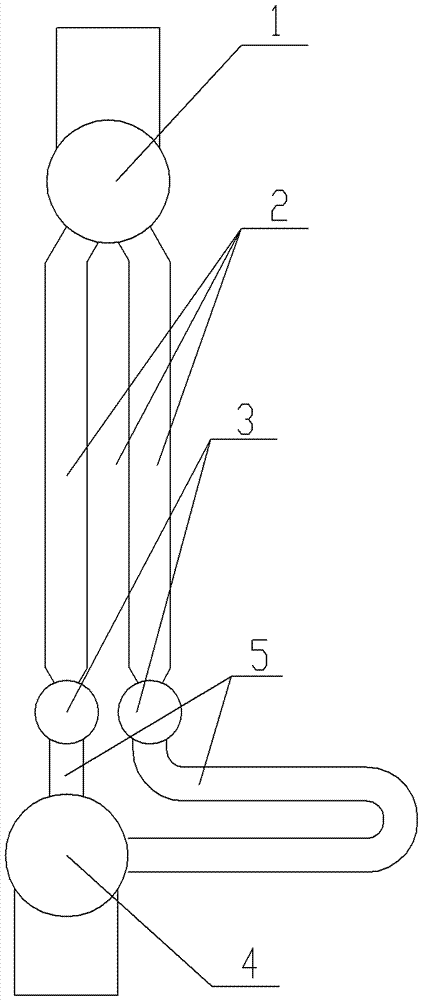

[0009] See figure 2 , image 3 As shown, a waste heat boiler reheater tube panel arrangement structure includes an upper header 1 and a lower header 2, a heating surface tube 2 is arranged between the upper header 1 and the lower header, and the lower header 1 includes two One auxiliary header 3 and one main header 4, the heating surface pipe 2 is connected to the upper header 1 and the auxiliary header 3, the auxiliary header 3 is connected to the main header 4 through the expansion pipeline 5, away from the side of the flue gas intake direction The expansion pipeline 5 is an annular pipeline, as can be seen from the figure, the annular pipeline length of the three rows of heating surface tubes 2 in embodiment one is the same as the annular pipeline length of four rows of heating surface tubes 2 in embodiment two Different, for different reheating systems, it is only necessary to adjust the length of the expansion loop to realize the scientific distribution of the working m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com