A multi-section bridge pipeline welding seam positioning flaw detection device

A flaw detection device and pipeline technology, which is applied in the direction of material analysis using radiation, can solve problems such as unstable quality and low efficiency of flaw detection, and achieve the effects of improving flaw detection quality, expanding the scope of use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

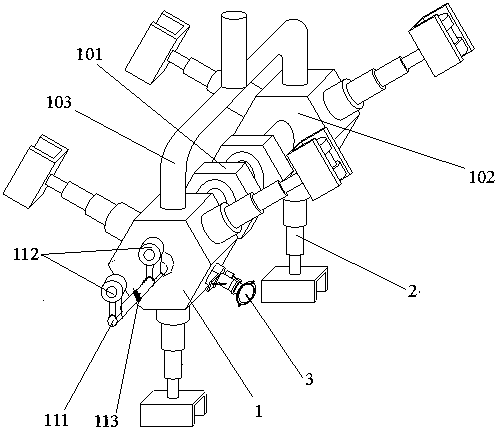

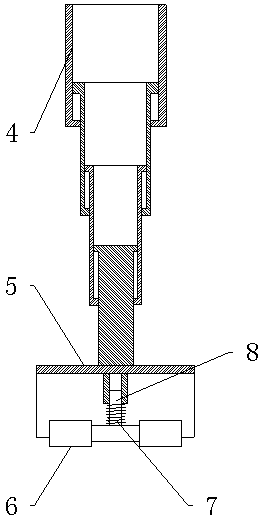

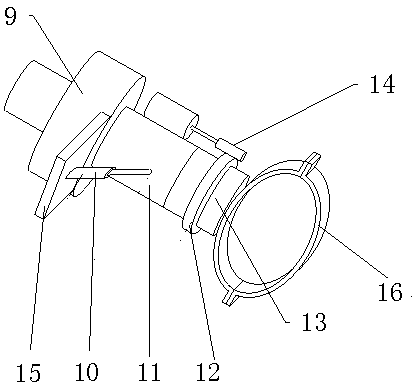

[0034] As shown in Figures 1-4, a multi-section bridge pipeline welding seam positioning flaw detection device of this patent includes a first cavity-type end head 1, a universal joint connector 101, and a second cavity-type end head 102 , walking mechanism 2, auxiliary mechanism 3, gamma source accommodation and conveying positioning unit, light emitting unit;

[0035]The outer edge of the first cavity-type end 1 and the second cavity-type end 102 is evenly provided with a running mechanism 2, and the auxiliary mechanism 3 is arranged on the first cavity-type end 1; the first cavity-type end 1 and The second cavity type terminal 102 is connected by two universal joint connectors 101 connected in series, and the centers of the first cavity type terminal 1, the second cavity type terminal 102 and the two universal joint connectors 101 are It is hollow, and a hollow channel is formed in the center of the axis after connection; the first cavity-type end 1 and the second cavity-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com