Optical cable peeling device

A technology of optical cable and guide wheel, applied in the field of optical cable stripping device, can solve the problems of low stripping efficiency, slow stripping speed, instability, etc., and achieve the effect of ensuring stripping efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

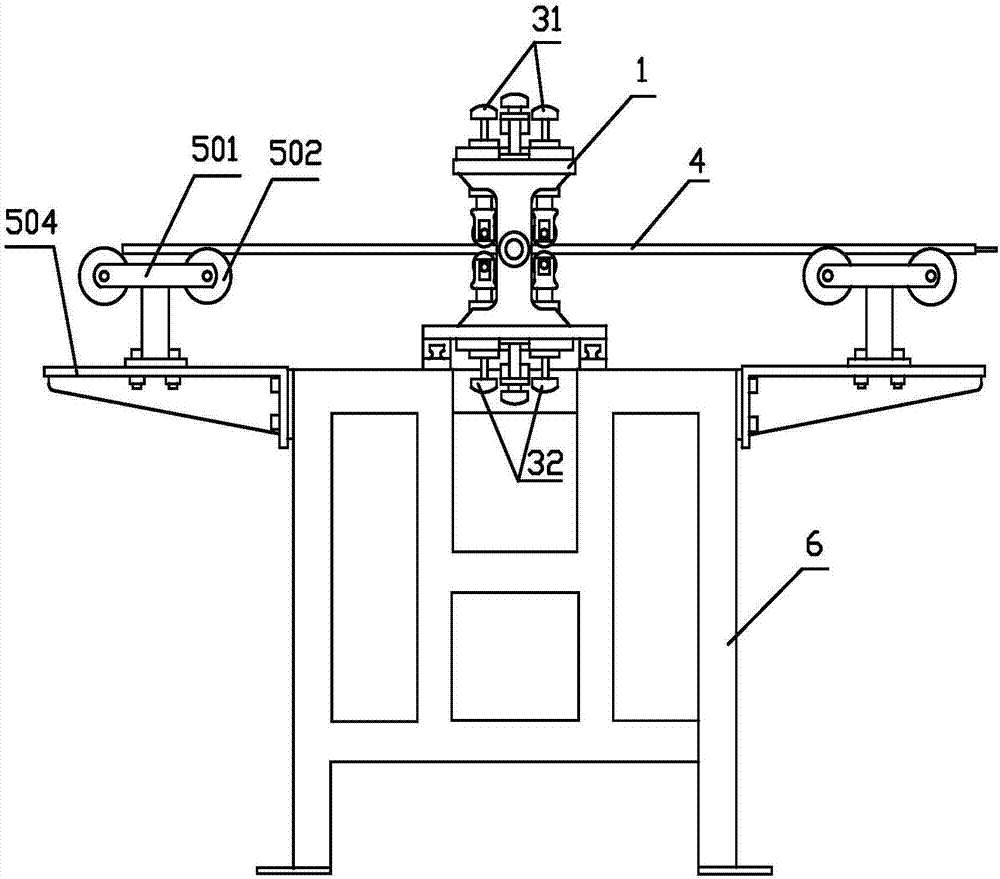

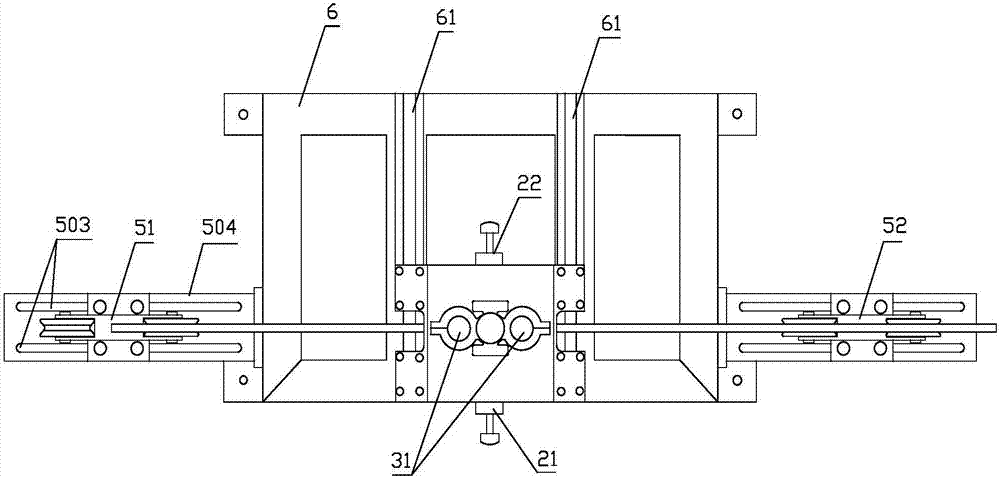

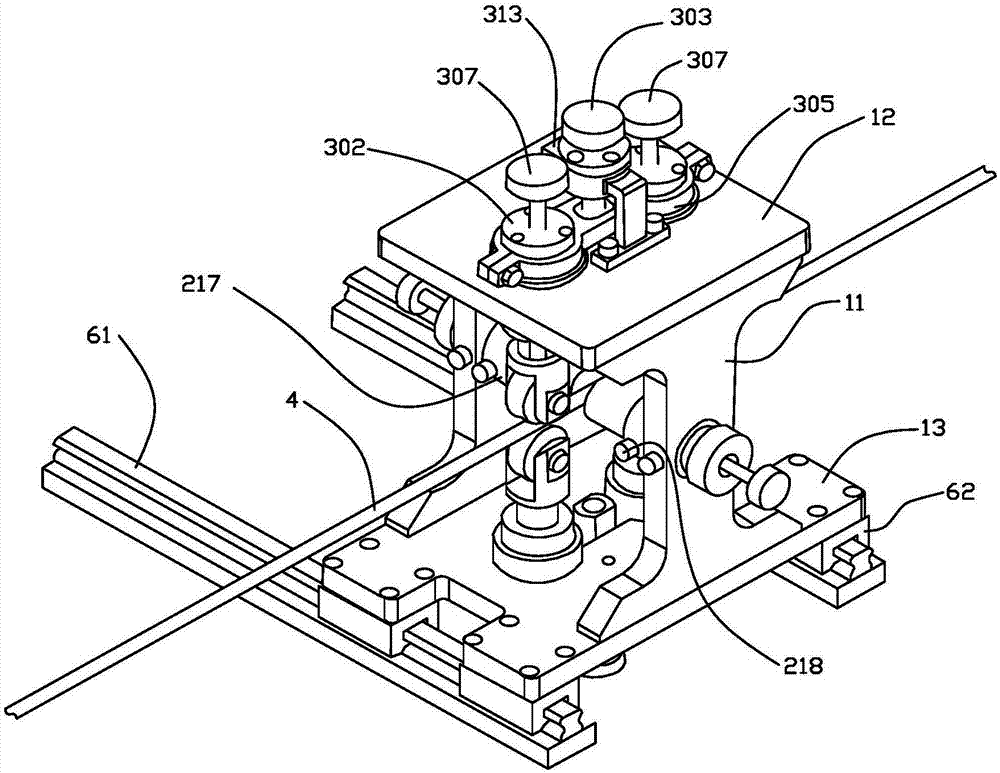

[0056] Such as Figure 1-9 As shown, the present invention provides a kind of optical cable stripping device, comprises frame 6 and machine head 1, and described machine head 1 is fixed on the frame 6, and machine head 1 comprises the side plate 11 that two board faces are oppositely arranged, and The top plate 12 and the bottom plate 13 connected with the two side plates 11 form a frame structure with a rectangular cross section. Correspondingly be provided with front cutter head 21 and rear cutter head 22 on two side plates 11, all be provided with blade 201 on front cutter head 21 and rear cutter head 22, the blade 201 on the front cutter head 21 and rear cutter head 22 is positioned at two sides. Between the two side plates 11 and the blades on the blade 201 are located on a horizontal line facing each other. The top plate 12 is provided with an upper guide wheel set 31, the bottom plate 13 is provided with a lower guide wheel set 32, and the upper guide wheel set 31 and ...

Embodiment 2

[0058] Further improvement on the basis of Embodiment 1, the front cutter head 21 and the rear cutter head 22 have the same structure, and both include a positioning sliding sleeve 202 arranged on the side plate 11, and a through hole is opened on the side plate 11, and a through hole is formed in the through hole. The cutter head cover 217 is installed on the top, and the positioning sliding sleeve 202 is fixedly inserted in the cutter head cover 217 and fixed by the bolt 218. A cutter body 203 , a cutter body connecting nut 204 and an adjusting screw shaft 205 are sequentially provided in the positioning sliding sleeve 202 along the axial direction. A mounting groove 206 is provided in the cutter body 203, and the mounting groove 206 is used to accommodate the blade 201 and extends along the long axis direction of the cutter body 203; the adjusting screw shaft 205 is provided with a through hole 207 extending in the axial direction, and the through hole 207 A limit screw 208...

Embodiment 3

[0062] Further improvement on the basis of Embodiment 2, the upper guide wheel set 31 and the lower guide wheel set 32 have the same structure, and both include two columnar connecting parts 302 correspondingly penetrating through the top plate 12 and the bottom plate 13, and the columnar connecting parts 302 include The sliding sleeve 306 and the spring adjusting screw rod 307 are provided with through holes on the top plate 12 and the bottom plate 13, the through holes are covered with a copper sleeve, and the sliding sleeve 306 is sleeved in the copper sleeve. The sliding sleeve 306 includes a first through hole 308 and a second through hole 309 in the axial direction, the inner diameter of the first through hole 308 is smaller than the inner diameter of the second through hole 309, the side wall of the spring adjustment screw 307 is threaded with the first through hole 308 connected, and the end of the spring adjusting screw 307 screwed into the sliding sleeve 306 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com