SMD lamp bead

A lamp bead, a new type of technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problem of not being able to change the series and parallel relationship of internal LED chips, and achieve a practical and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

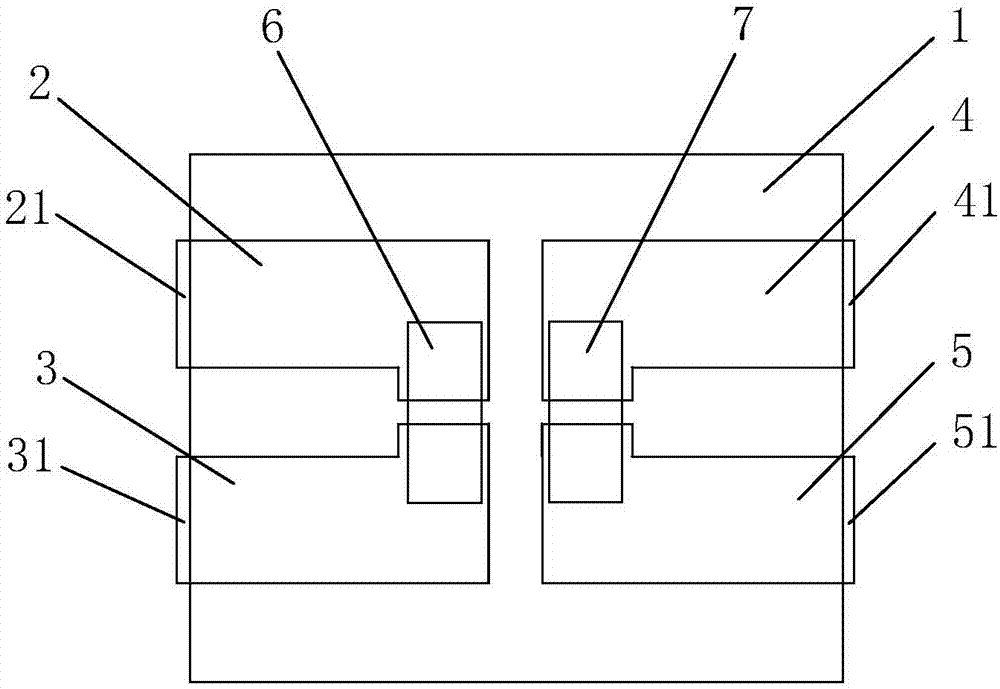

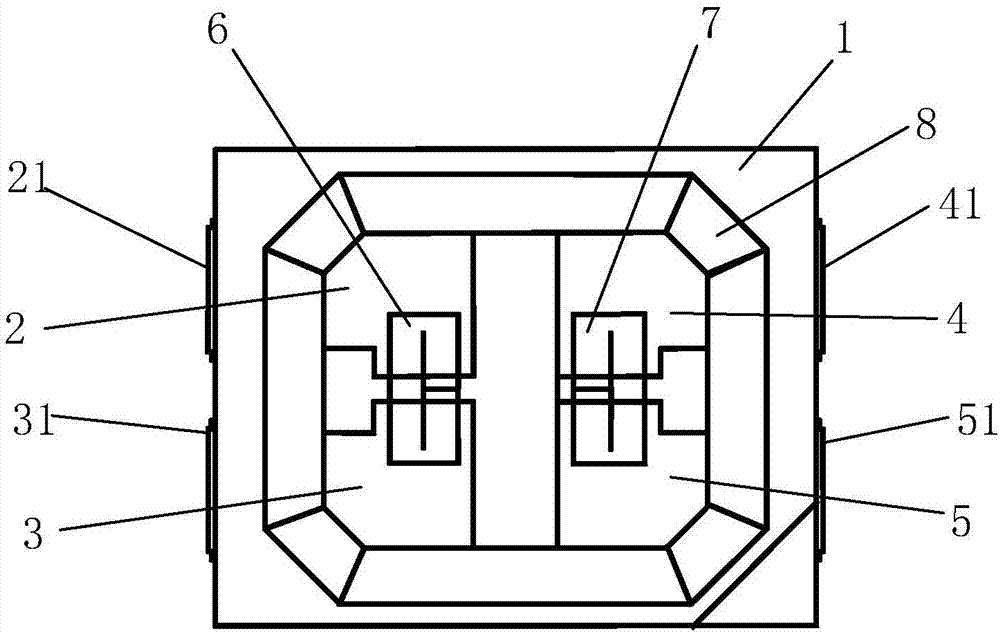

[0017] Such as figure 1 and 2 As shown, this embodiment provides a new type of SMD lamp bead, including a base 1 and an LED chip. The base 1 is provided with a packaging table and a conductive sheet provided on the packaging table for connecting the LED chip. The package There are four conductive sheets on the table, and each conductive sheet extends from the inside to the outside along the packaging table to form conductive pins on both sides of the packaging table, and the conductive sheets are symmetrically arranged on the base 1 in groups of two. On the top, LED chips are connected between the two conductive sheets of each group, and the packaging table is covered with a packaging layer 8 for packaging LED chips, wherein the packaging layer 8 is fluorescent colloid, and the base 1 is a polymer non-conductive material .

[0018] The conductive sheet that this embodiment adopts is L-shaped structure, with figure 2 As an example, the conductive sheet is divided into the f...

Embodiment 2

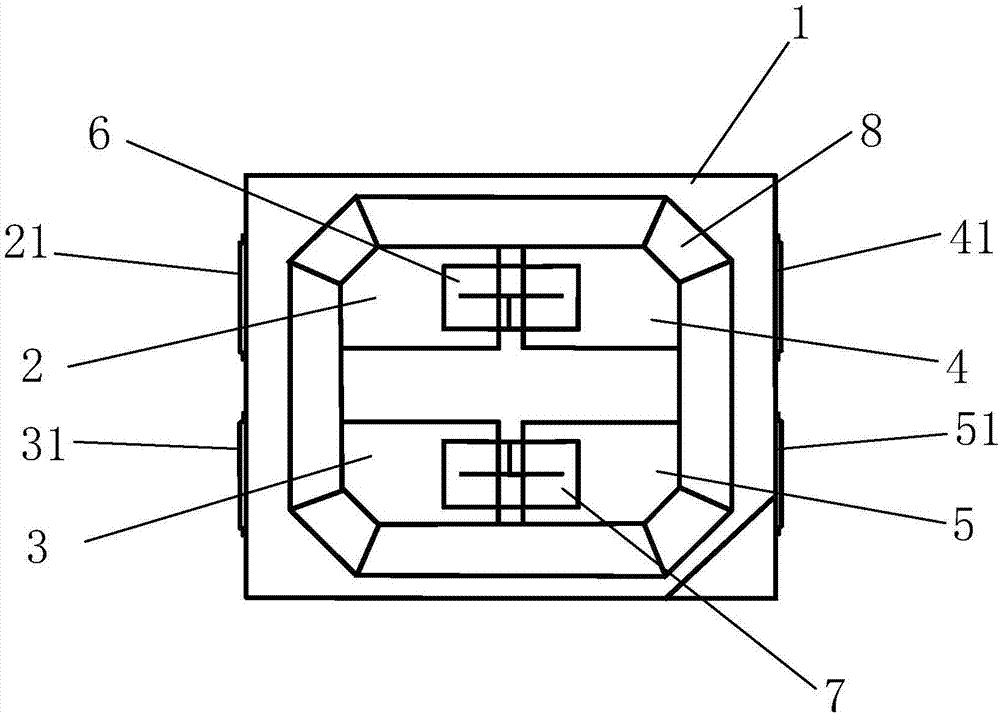

[0022] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the conductive sheet adopts a rectangular structure, and the conductive sheets are divided into two groups according to the upper and lower sides, wherein, the first conductive sheet 2 and the third conductive sheet 4 form a group, and the second conductive sheet 3 and the third conductive sheet The fourth conductive sheet 5 is another group, the first LED chip 6 is connected between the first conductive sheet 2 and the third conductive sheet 4, and the second LED chip 7 is connected between the second conductive sheet 3 and the fourth conductive sheet 5 Between, the series-parallel connection mode is the same as that of Embodiment 1.

[0023] When the external circuit connects the second conductive pin 31 to the third conductive pin 41, and the first conductive pin 21 and the fourth conductive pin 51 are respectively connected to positive and negative poles, the two LED chips are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com