Closed CNC machine guide rail protective cover

A CNC machine tool, closed technology, applied in the field of CNC machine tools, can solve the problems of large application range, large volume, poor guide rail protection effect, etc., and achieve the effect of small size, small limitations, simple and convenient use and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

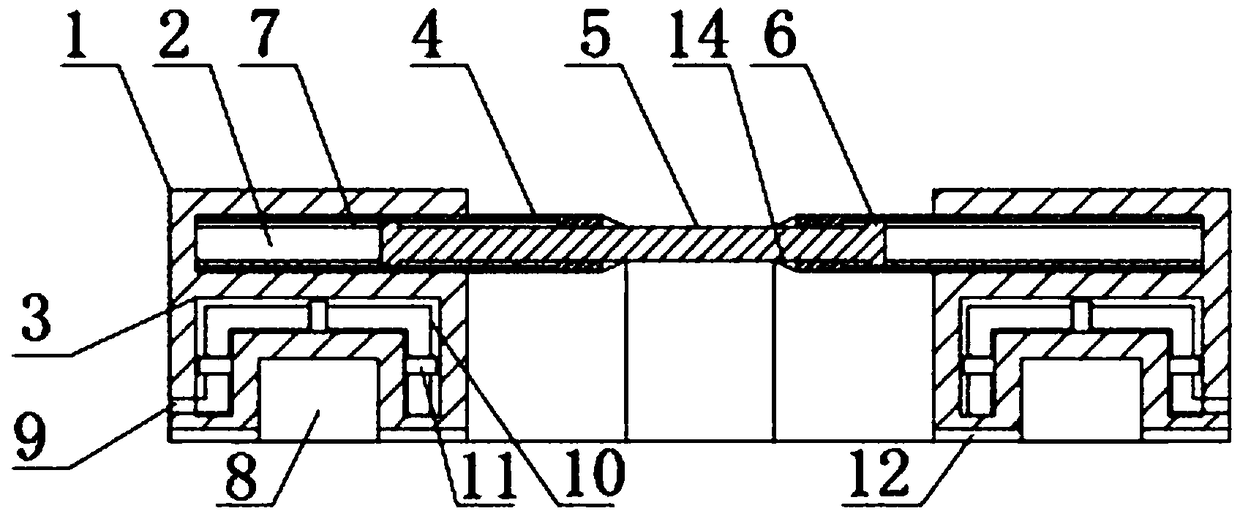

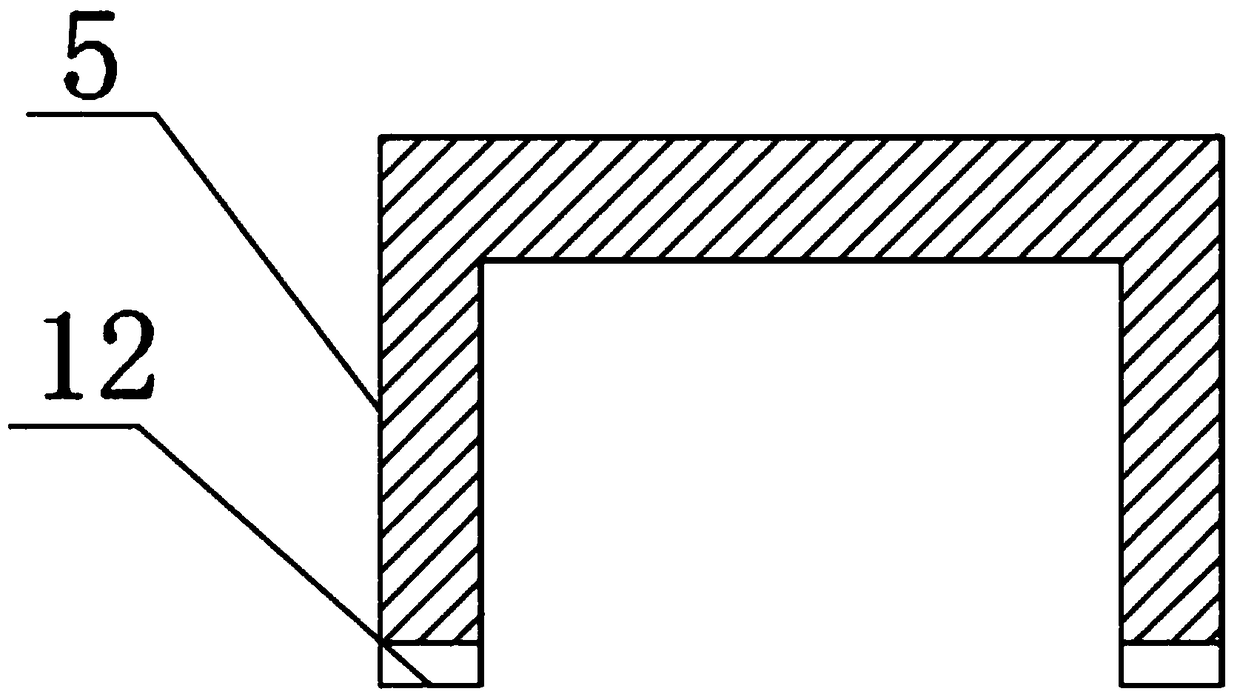

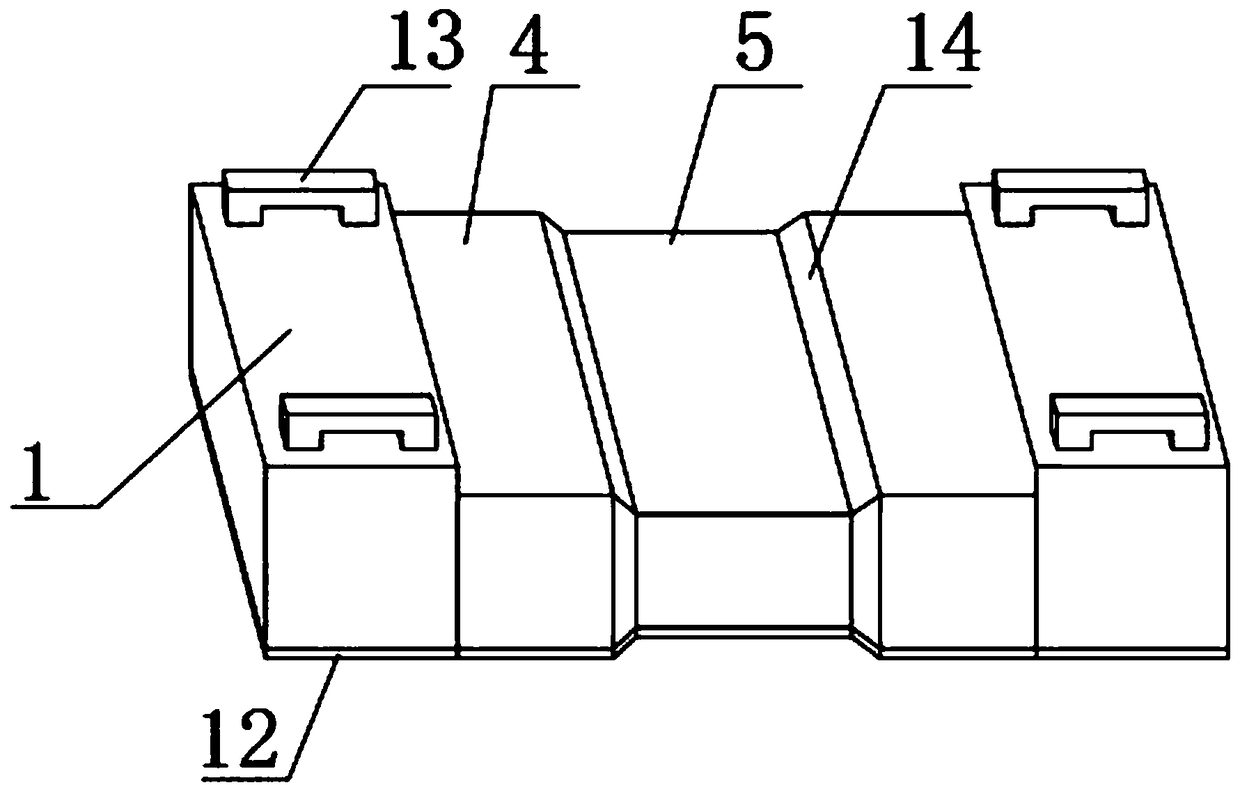

[0017] Such as figure 1 , 2 , Shown in 3, the closed CNC machine tool rail protective cover, wherein:

[0018] A closed protective cover for guide rails of CNC machine tools, including two left and right cover bodies 1, the cover body includes an upper telescopic chamber 2 and a lower protective chamber 3, one side of the telescopic chamber is an open end, and the open end extends axially to form a The telescopic arm 4 is slidingly connected with a telescopic joint 5 in the telescopic arm. The telescopic joint is cylindrical in shape with three sides. The left and right ends of the telescopic joint are provided with sliding shafts 6, and the inner wall of the telescopic arm is provided with slide rails 7. The bottom of the protection chamber is inwardly recessed to form a strip-shaped guide rail prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com