Linkage control system of PET bottle cap power conveying system

A conveying system and linkage technology, applied in the field of linkage control devices, can solve problems such as unfavorable health of operators, useless discharge of compressed air, noise pollution, etc., and achieve the effects of reducing noise pollution, preventing energy waste, and preventing physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

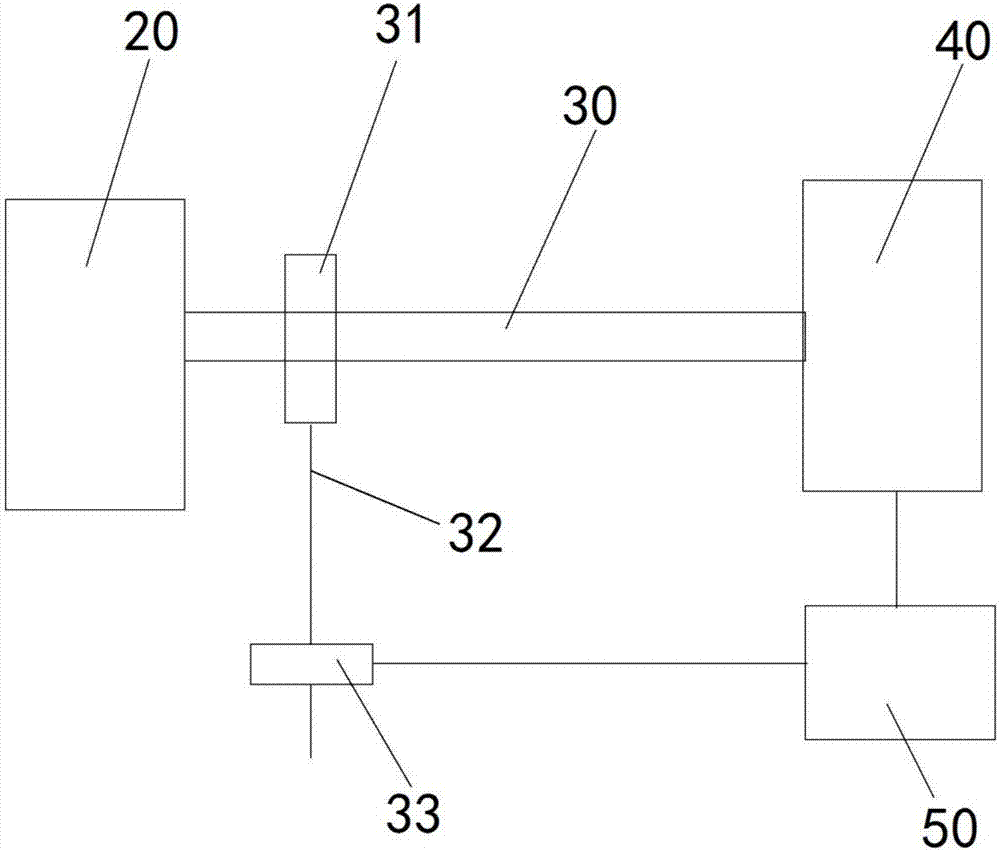

[0012] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following describes in detail in conjunction with the embodiments and accompanying drawings.

[0013] refer to figure 1 , the linkage control device of the power conveying system for PET bottle caps of the present invention includes a flipping bucket 20 , a cap conveying channel 30 , a filling and capping machine 40 and a control panel 50 . An air blowing nozzle 31 is arranged on the cap conveying passage 30, and the air blowing nozzle 31 is connected with a compressed air pipeline 32. The compressed air pipeline 32 is provided with a linkage solenoid valve 33, which controls the switch of the compressed air. The filling and capping machine 40 includes a main motor (not shown).

[0014] The main motor is connected with the control panel 50 , and sends the start-stop signal of the main motor to the control panel 50 . The linkage solenoid valve 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com