High-flexibility polyvinyl chloride resin composition and high-flexibility towline cable

A polyvinyl chloride resin, drag chain cable technology, applied in plastic/resin/wax insulators, circuits, electrical components, etc., can solve the problems of inability to adapt to the cable industry, poor flexibility and wear resistance of drag chain cables, etc. Strong compressive and tensile strength, anti-oil pollution, stable performance and reasonable ratio

Inactive Publication Date: 2017-12-19

东莞市宏昱新材料有限公司

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the drag chain cables on the market are generally poor in flexibility and wear resistance, and cannot adapt to the high-speed development of the cable industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 4

[0033] The flexible towline cable obtained in Example 3 is tested for performance, and Table 2 shows the results of the performance test.

[0034] Table 2

[0035]

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of high molecular processing materials, and in particular relates to a high-flexibility polyvinyl chloride resin composition and a high-flexibility towline cable. The high-flexibility towline cable provided by the invention is prepared from the high-flexibility polyvinyl chloride resin composition; all components are reasonably proportioned and have a synergetic effect, so that the towline cable provided by the invention has the advantages of good flexibility, easiness for bending, bending resistance, rubbing resistance, strong compression resisting and tension resisting capabilities, oil dirt resistance and stable properties, and meets testing standards of the towline cable.

Description

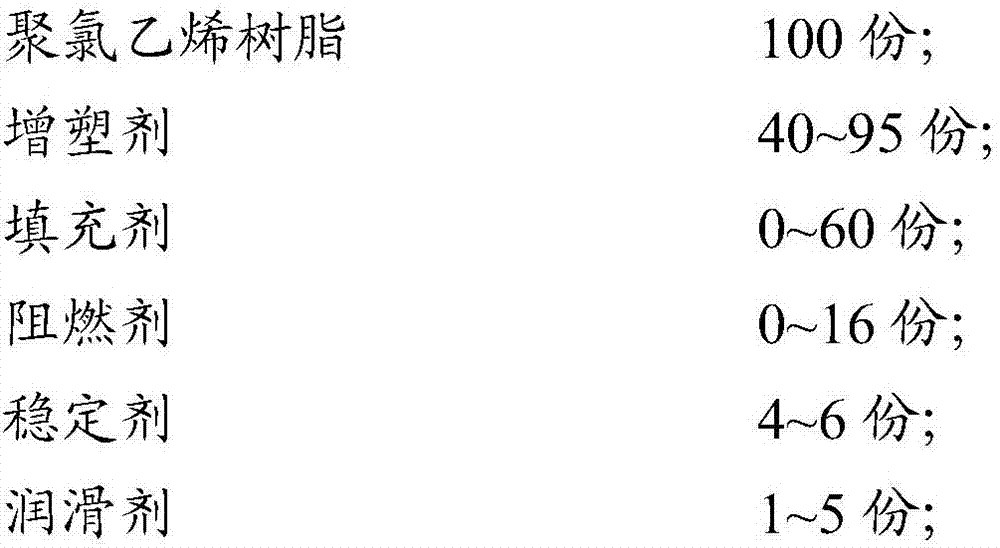

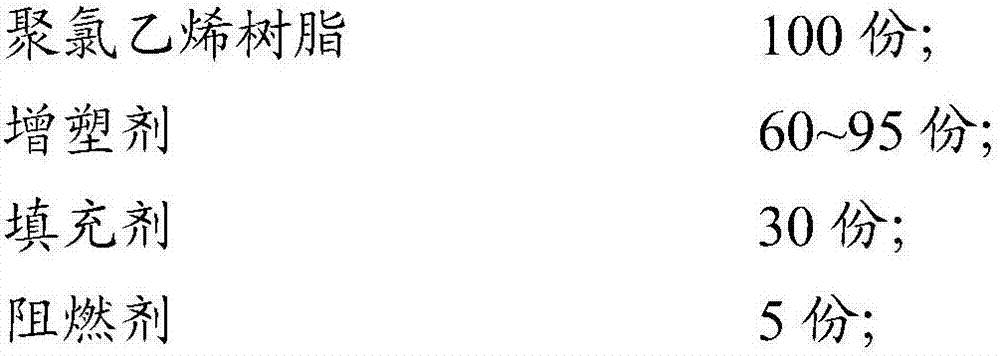

technical field [0001] The invention belongs to the field of polymer processing materials, and in particular relates to a highly flexible polyvinyl chloride resin composition and a highly flexible drag chain cable. Background technique [0002] In the occasion where the equipment unit needs to move back and forth, in order to prevent the cable from being entangled, worn, pulled off and scattered, the cable is often put into the cable drag chain to protect the cable, and the cable can also move back and forth with the drag chain. This kind of cable It is called a drag chain cable, and it can also be called a drag cable or a tank chain cable. Drag chain cables are mainly used on machine tools, and they need to move back and forth along with the drag chain during use, so they have extremely high requirements for the flexibility and wear resistance of the cables. However, the drag chain cables on the market are generally poor in flexibility and wear resistance, and cannot adapt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08L23/06C08K13/02C08K5/1515C08K3/26C08K3/22H01B3/44

CPCC08L27/06C08K2003/265C08K2201/014C08L2203/202C08L2205/025C08L2205/035H01B3/443C08L23/06C08K13/02C08K5/1515C08K3/26C08K3/2279

Inventor 肖和伟

Owner 东莞市宏昱新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com