Outer cover support system and method of use

A technology of support system and outer cover plate, which is applied in construction, artificial island, infrastructure engineering and other directions, can solve the problems of bending of outer cover plate 4 and damage of outer cover plate 4, etc., and achieves reduction of shaking strength, convenient operation, Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

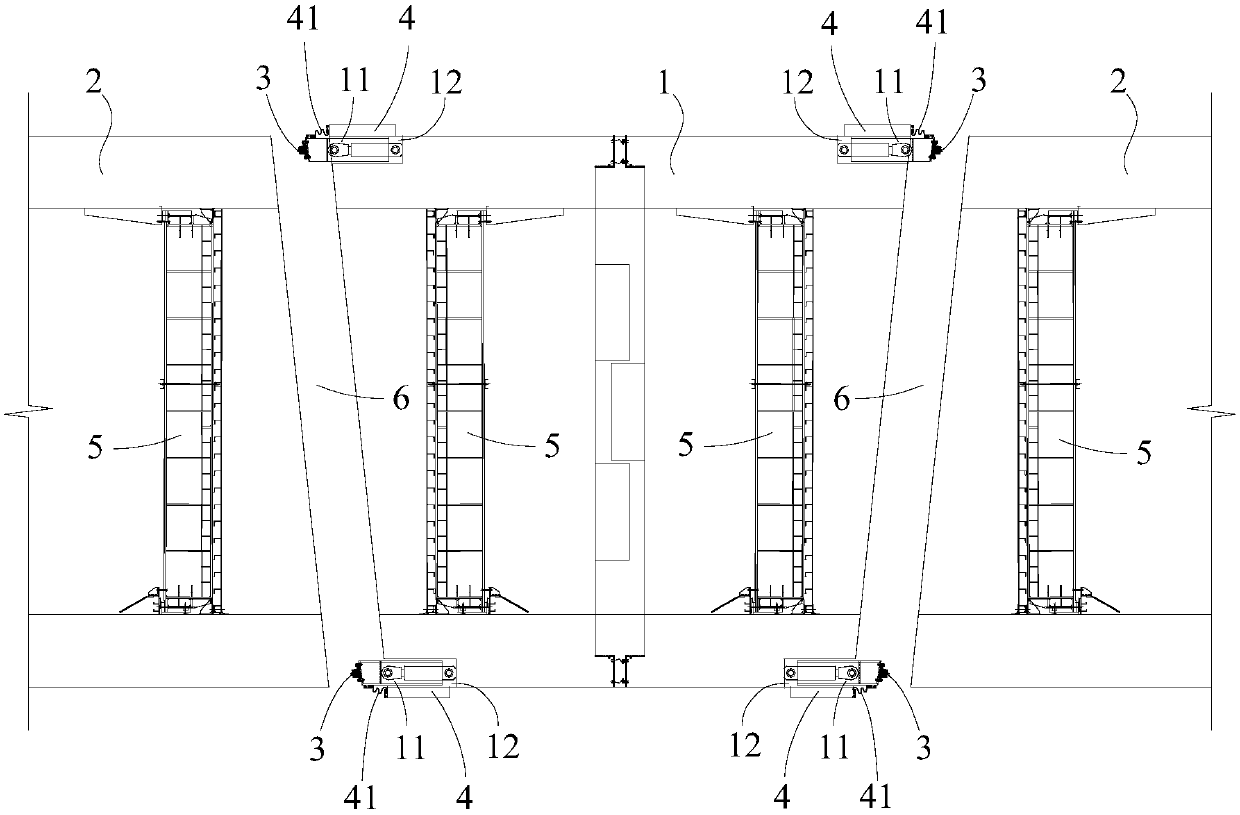

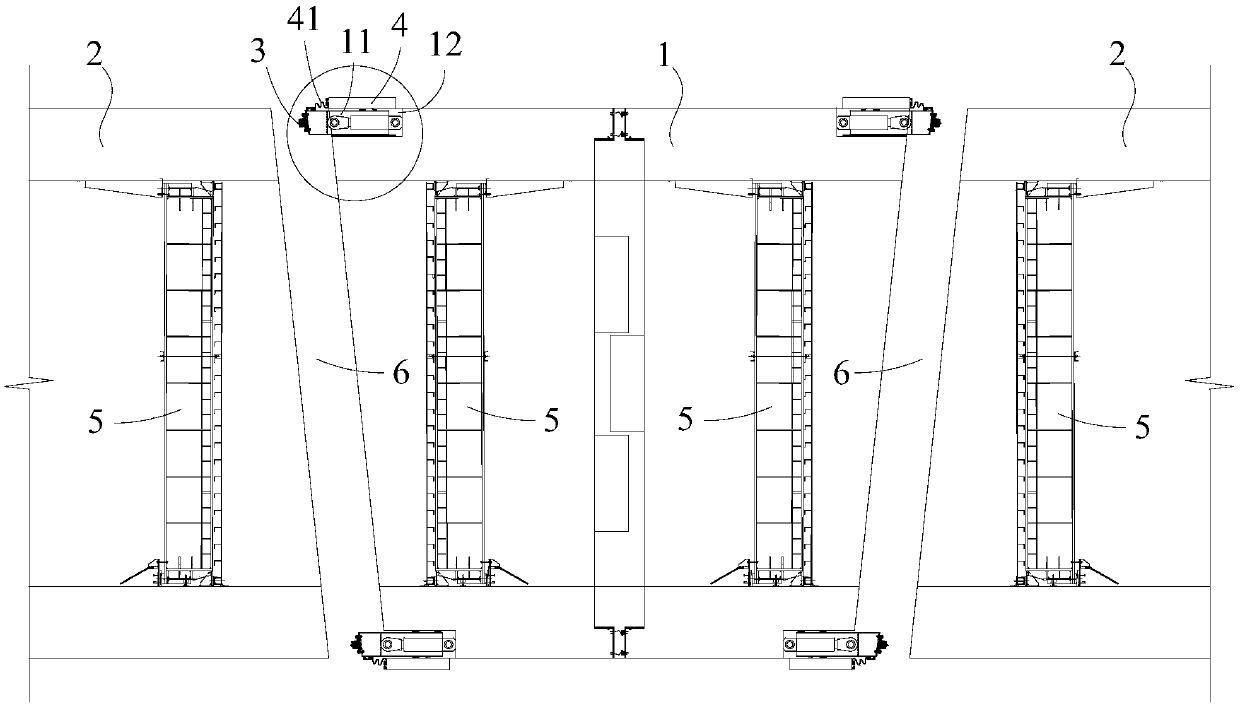

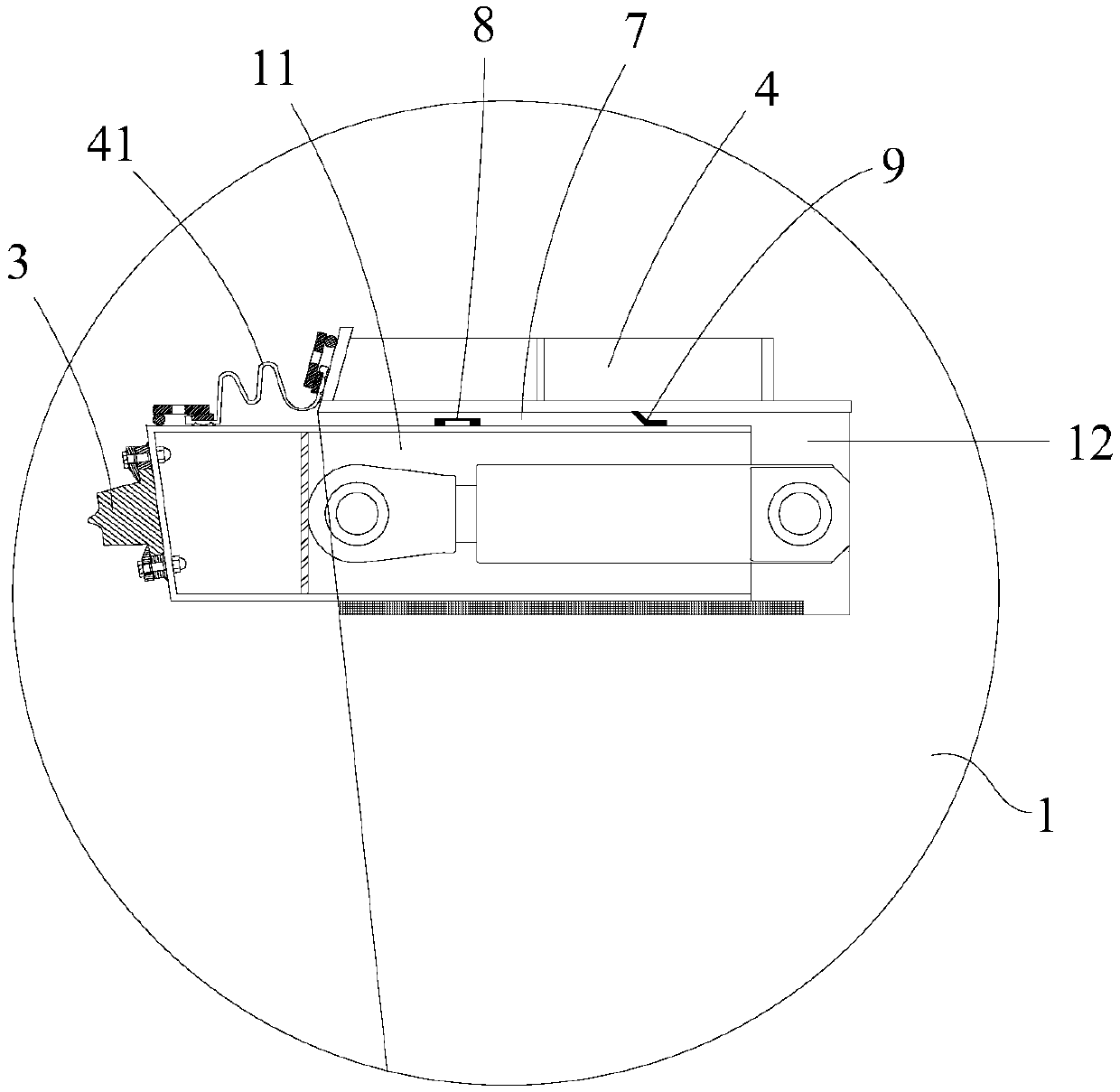

[0040] Such as Figure 1-5 As shown, in an outer cover support system according to the present invention, a plurality of supports 8 are provided in the gap 7 between the closed annular push beam 11 and the closed annular outer cover 4 .

[0041] All the supports 8 are connected to the outer wall of the pushing beam 11 along the circumferential direction of the pushing beam 11, after the pushing beam 11 pushes the first water stop belt 3 to stop the water The support 8 is located at the lower part of the free end of the outer cover plate 4, and the first water stop 3 is a Gina water stop.

[0042] As a preferred solution of this embodiment, all the supports 8 are evenly arranged to balance the external water pressure; The spacing is 1 cm. With this structure, it is ensured that the support 8 does not touch during the sliding process relative to the outer cover plate 4, and the friction force during the movement of the pushing beam 11 is reduced. At the same time, the outer cov...

Embodiment 2

[0048] Such as Figure 1-5 As shown, the method for using an outer cover support system according to the present invention, applying the outer cover support system as described in Embodiment 1, includes the following steps:

[0049] A. After the final joint 1 is placed, adjust its position to align with the immersed tubes 2 on both sides;

[0050] B. The pushing beam 11 moves relative to the final joint 1, and drives the first waterstop 3 to move to the corresponding end surface of the immersed tube 2;

[0051] C. All the supports 8 move with the push beam 11, and move to the free end of the outer cover plate 4;

[0052] D. When the first waterstop 3 is closely attached to the corresponding end surface of the immersed tube 2 , all the supports 8 move to the lower part of the free end of the outer cover plate 4 .

[0053] Using the method of using the outer cover plate support system of the present invention, the support 8 arranged in the gap 7 moves with the pushing beam 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com