temperature sensitive controller

A controller and sensitive technology, applied in the direction of temperature control, mechanical control device, control/regulation system, etc., can solve the problem of low universal matching of temperature control sensitive controllers, reducing the contact life of contact switches, and affecting product safety and life. and other problems, to achieve the effect of small and practical structure, low insertion depth requirements, and elimination of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

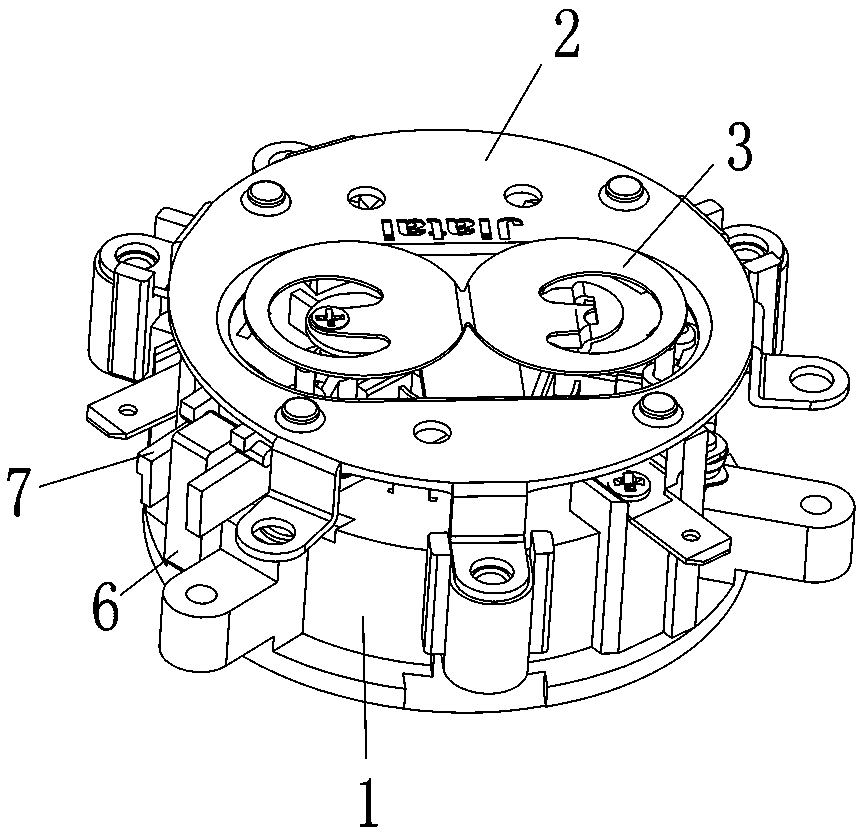

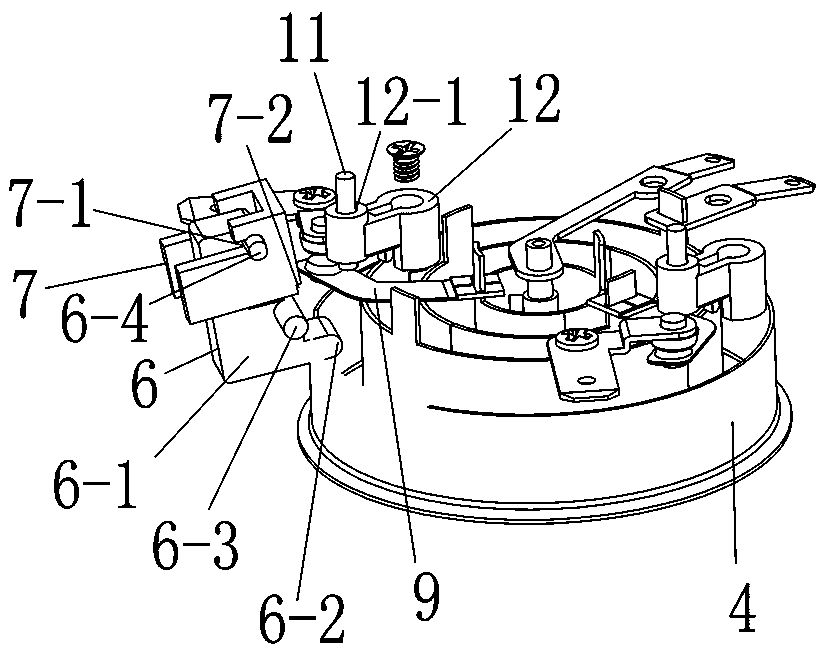

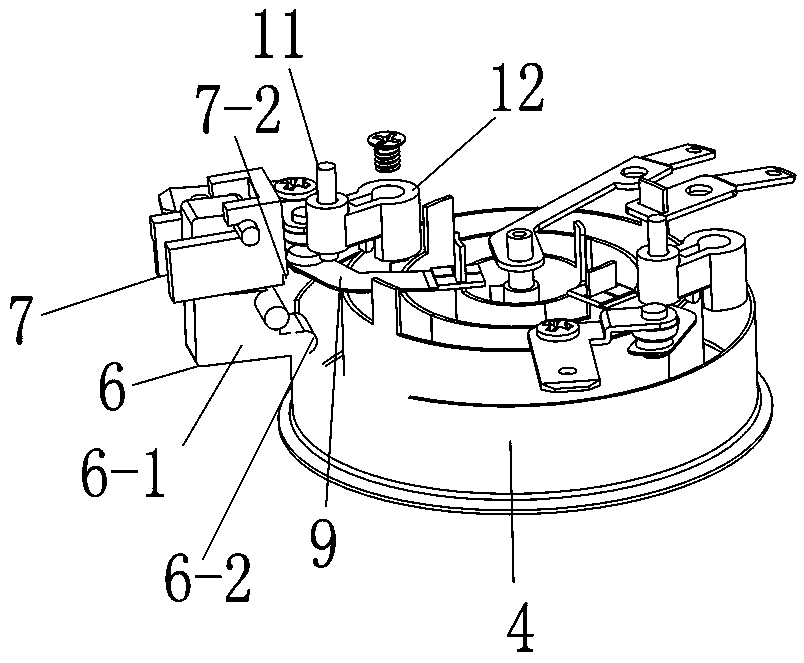

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a specific embodiment of the temperature-sensitive controller of the present invention includes a main casing 1, a fixed plate 2 fixedly installed on the main casing 1, and a thermal bimetallic actuator fixedly installed on the fixed plate 2 3. Several concentric cylindrical annular electrodes 4 are installed in the annular groove on the back of the main housing 1, and the concentric cylindrical annular electrodes are connected to corresponding lugs installed on the front of the main housing. One or more lugs are provided with a contact switch, and the contact switch includes a static contact, a moving contact arm 9, a moving ceramic rod 11, and a limit hole 12-1 to support the limit moving ceramic rod. The support member 12 of the rod 11, the movable end of the movable contact arm is below the thermal bimetallic actuator 3, and the movable end of the movable contact arm has a contact that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com