A kind of bismuth stannate/silver-silver chloride photocatalytic film material and preparation method thereof

A thin-film material, bismuth stannate technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as secondary pollution, difficulty in powder catalyst recovery, and low utilization rate of visible light, and achieve Easy to recycle, the preparation process is green and environmentally friendly, and the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

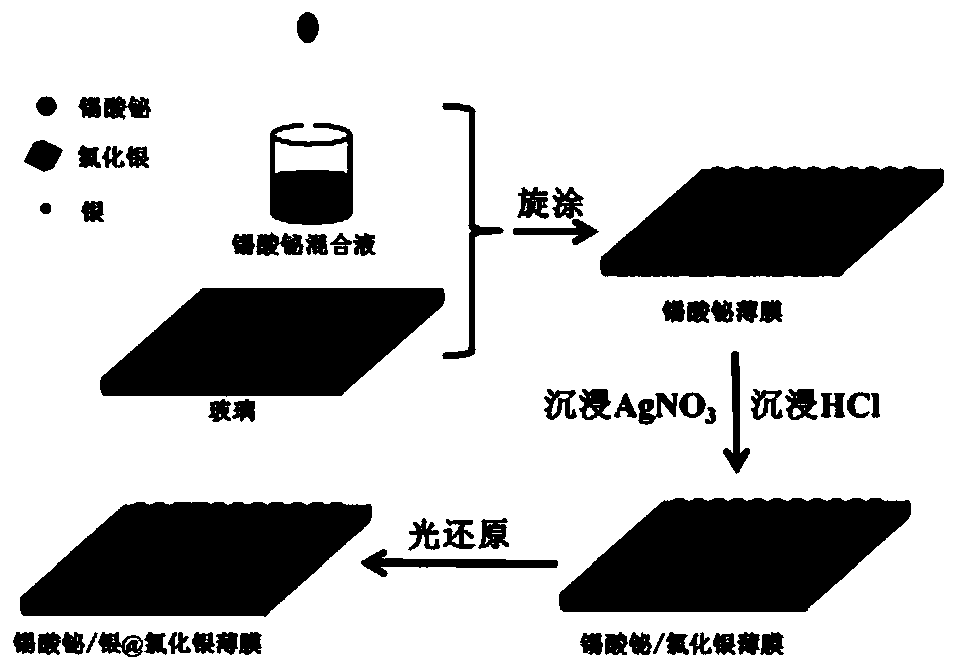

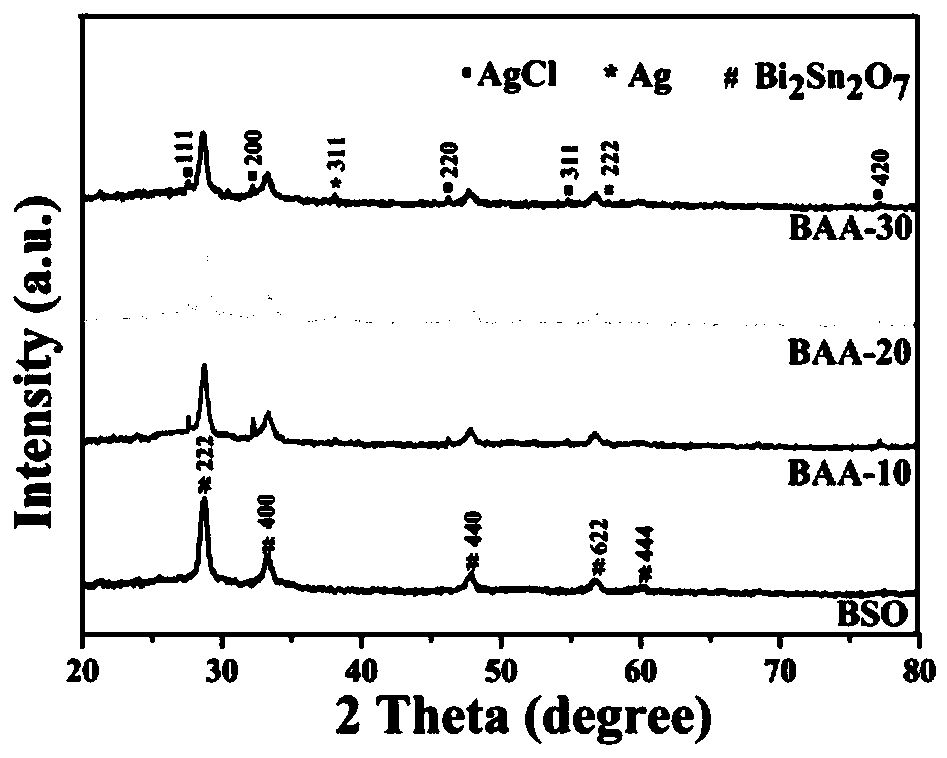

Method used

Image

Examples

Embodiment 1

[0035] The present invention prepares nano Bi by hydrothermal synthesis method 2 sn 2 o 7 powder. Weigh 4.38g of Bi(NO 3 ) 3 ·5H 2 O and 2.70 g of K 2 SnO 3 ·3H 2 O and the two substances were thoroughly mixed in 90 mL of deionized water, and the pH value of the mixed liquid was adjusted to 12 by adding ammonia water drop by drop under magnetic stirring. Stirring was continued for one hour, then the mixture was transferred to a 200 mL polytetrafluoroethylene hydrothermal reactor and deionized water was added to make up to 160 mL. Raise the temperature to 180° C., keep it for 24 hours, then cool naturally, filter with suction and vacuum-dry at 60° C. to obtain light yellow nano-bismuth stannate powder.

[0036] The present invention adopts common glass flake as base material 15mm * 20mm, because the surface of base material is easy to absorb impurities that may affect Bi 2 sn 2 o 7 Therefore, the substrate should be cleaned before spin coating to prepare a film with...

Embodiment 2

[0050] For comparison, different dispersants were used to disperse bismuth stannate powder to prepare bismuth stannate thin films. Wherein bismuth stannate powder is also prepared by hydrothermal synthesis. Weigh 4.38g of Bi(NO 3 ) 3 ·5H 2 O and 2.70 g of K 2 SnO 3 ·3H 2 0 and two kinds of materials are fully mixed in 90mL deionized water, under magnetic stirring, by dropwise adding ammoniacal liquor, the pH value of mixed liquid is adjusted to 12. Stirring was continued for one hour, then the mixture was transferred to a 200 mL polytetrafluoroethylene hydrothermal reactor, and deionized water was added to make up to 160 mL. The temperature was raised to 180°C, kept for 24h, then naturally cooled, suction filtered and vacuum-dried at 60°C to obtain light yellow nano-bismuth stannate powder.

[0051] The common glass sheet is used as the base material 15mm×20mm, because the surface of the base material is easy to absorb impurities, which may affect Bi 2 sn 2 o 7 There...

Embodiment 3

[0055] For comparison, different dispersants were used to disperse bismuth stannate powder to prepare bismuth stannate thin films. Wherein bismuth stannate powder is also prepared by hydrothermal synthesis. Weigh 4.38g of Bi(NO 3 ) 3 ·5H 2 O and 2.70 g of K 2 SnO 3 ·3H 2 0 and two kinds of materials are fully mixed in 90mL deionized water, under magnetic stirring, by dropwise adding ammoniacal liquor, the pH value of mixed liquid is adjusted to 12. Stirring was continued for one hour, then the mixture was transferred to a 200 mL polytetrafluoroethylene hydrothermal reactor, and deionized water was added to make up to 160 mL. The temperature was raised to 180°C, kept for 24h, then naturally cooled, suction filtered and vacuum-dried at 60°C to obtain light yellow nano-bismuth stannate powder.

[0056] The common glass sheet is used as the base material 15mm×20mm, because the surface of the base material is easy to absorb impurities, which may affect Bi 2 sn 2 o 7 There...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com