Cleaner packing bottle

A technology for packaging bottles and cleaning agents, which is applied in packaging, transportation and packaging, injection devices, etc., can solve problems such as button reset failure, and achieve the effects of preventing work failure, easy replacement and maintenance, and wide suction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

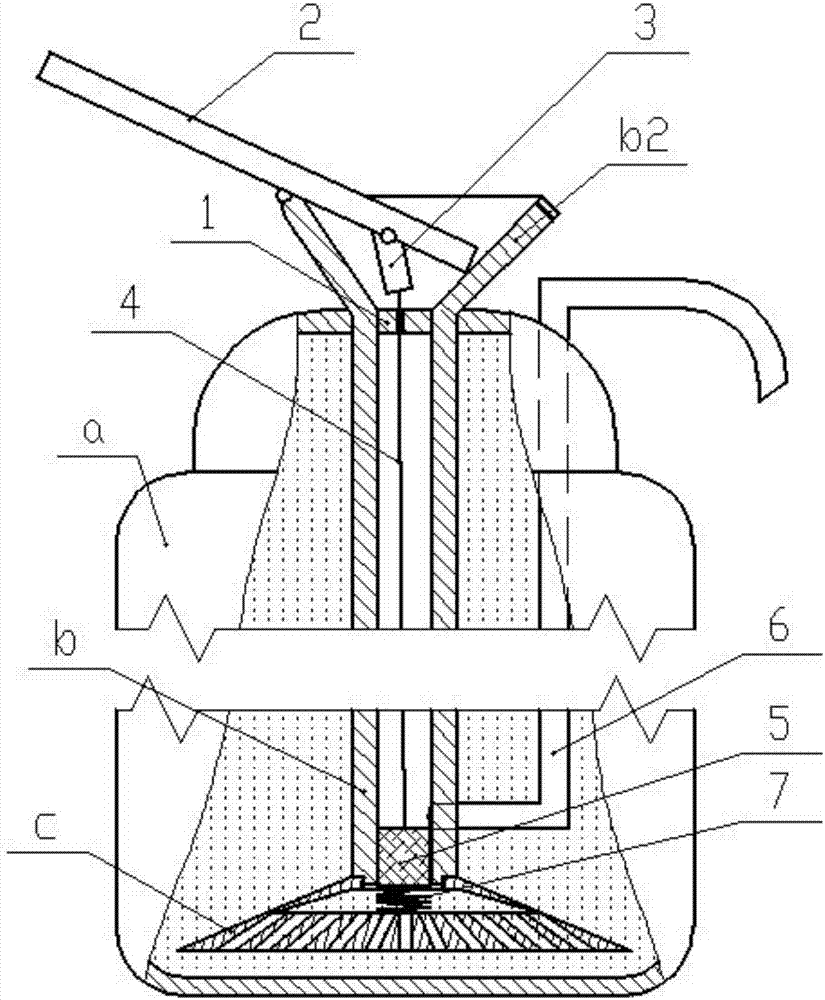

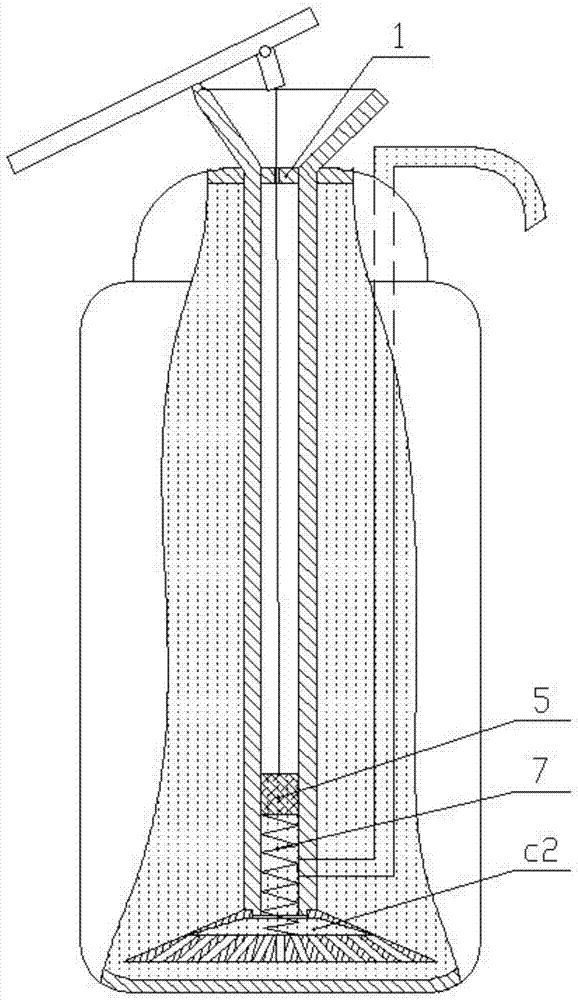

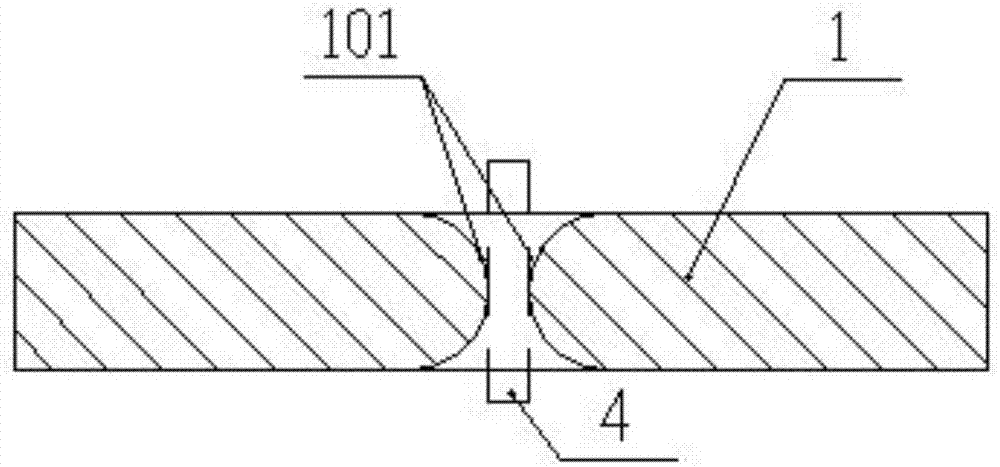

[0021] Such as figure 1 - As shown in 2, a cleaning agent packaging bottle includes a bottle body a containing cleaning liquid and a spraying mechanism for pressing and spraying the cleaning liquid, and the spraying mechanism includes a straw b for directly sucking the cleaning liquid. The inlet end of the straw b is located in the cleaning solution in the bottle a. The top of the straw b protrudes from the top of the bottle a and the protruding part b2 is funnel-shaped, the large port of the protruding part b2 faces upwards, and its small port is blocked by the circular plate 1. A cover plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com