Chemical industry wastewater discharge pipe

A technology for sewage discharge and chemical industry, which is applied in the sewer system, water/sewage treatment, water/sewage treatment equipment, etc. It can solve the problem that the chemical industry sewage discharge pipe cannot adequately filter chemical components, and achieve a simple and novel structure. , widely used and recognized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

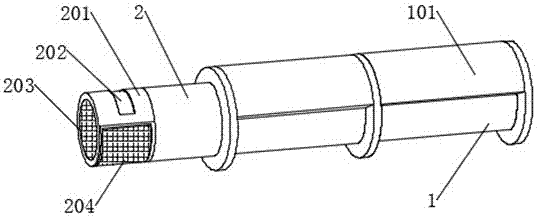

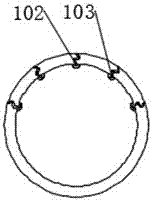

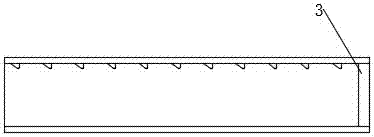

[0019] Embodiment one: if Figure 1 to Figure 4 As shown, a chemical industry sewage discharge pipe includes a reaction pipe 1, a liquid storage tank 101, a delivery pipe 102, a spray head 103, a filter pipe 2, a rotating head 201, a groove 202, a first filter screen 203, a second Filter screen 204, sealer 3, receiver 301 and baffle plate 302, several shower heads 103 are arranged on the inside of reaction tube 1, and these shower heads 103 are evenly arranged in a semicircular arc shape, filter tube 2 front end and The bottom is provided with a first filter 203 and a second filter 204.

[0020] In one embodiment, the shower heads 103 are provided with eleven groups, and each group is evenly distributed with five, and surround the upper surface arranged inside the reaction tube 1, the shower heads 103 can store the liquid The liquid inside the tank 101 is sprayed into the sewage, so that the chemical components in the sewage can react with the liquid to form solids.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com