Truss-type steel box beam diaphragm

A steel box girder and truss-type technology, applied in bridges, buildings, etc., can solve the problems of high steel volume index and poor technical and economical efficiency of solid-web diaphragms, and achieve easy maintenance, convenient construction, and increased internal space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

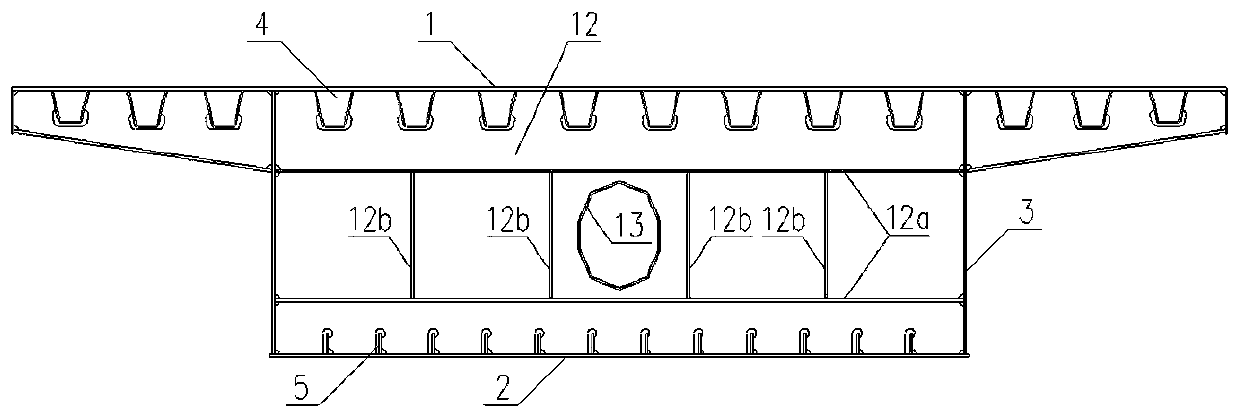

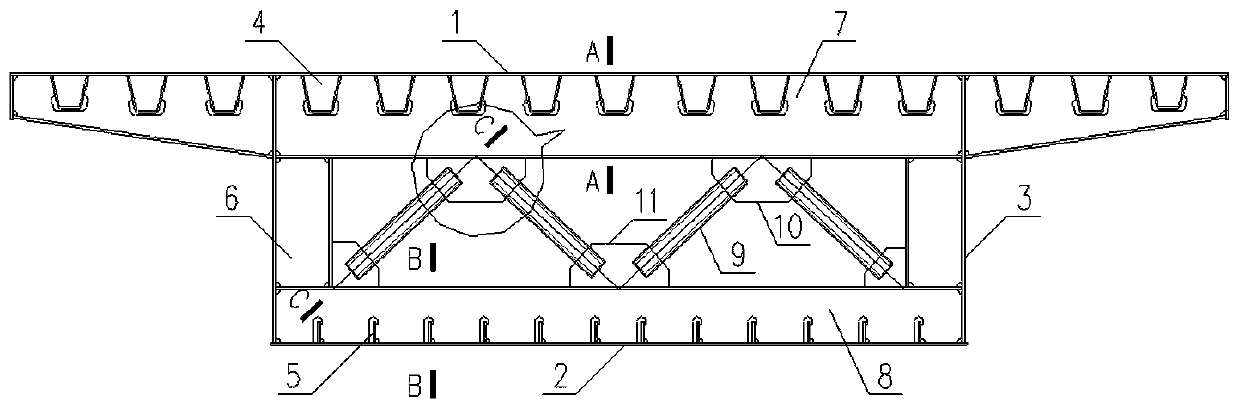

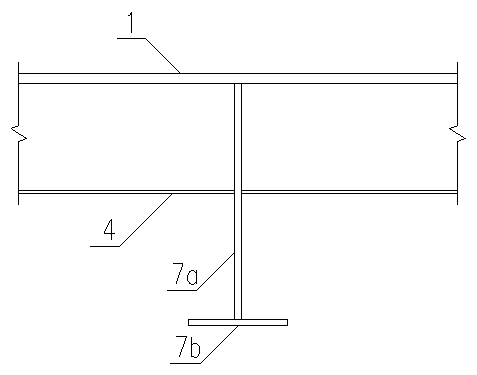

[0025] Example: such as figure 2 As shown, this embodiment provides a truss-type steel box girder diaphragm. The diaphragm is composed of truss upper chord 7 , truss lower chord 8 , truss web 9 , upper chord gusset 10 , lower chord gusset 11 and other components. Among them, the truss upper chord 7 is composed of a T-shaped member composed of a truss upper chord web 7a and a truss upper chord flange 7b, and the truss lower chord 8 is a T-shaped member composed of a truss lower chord web 8a and a truss lower chord flange 8b. The truss web member 9 is made up of circular section steel pipe 9a or channel steel 9b and other shaped steel.

[0026] In the truss-type diaphragm, the truss web 9 is welded to the truss upper chord 7 and the truss upper chord 8 through the upper chord gusset 10 and the lower chord gusset 11 respectively, forming a truss structure. The truss structure is welded with the steel box girder top plate 1, steel box girder bottom plate 2, and steel box girder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com