Sheet-material supporting device

A supporting device and supporting device technology, applied in the direction of coiling strips, transportation and packaging, metal processing, etc., to achieve the effect of simplifying the structure, reducing the formation of longitudinal wrinkles, and preventing transverse bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

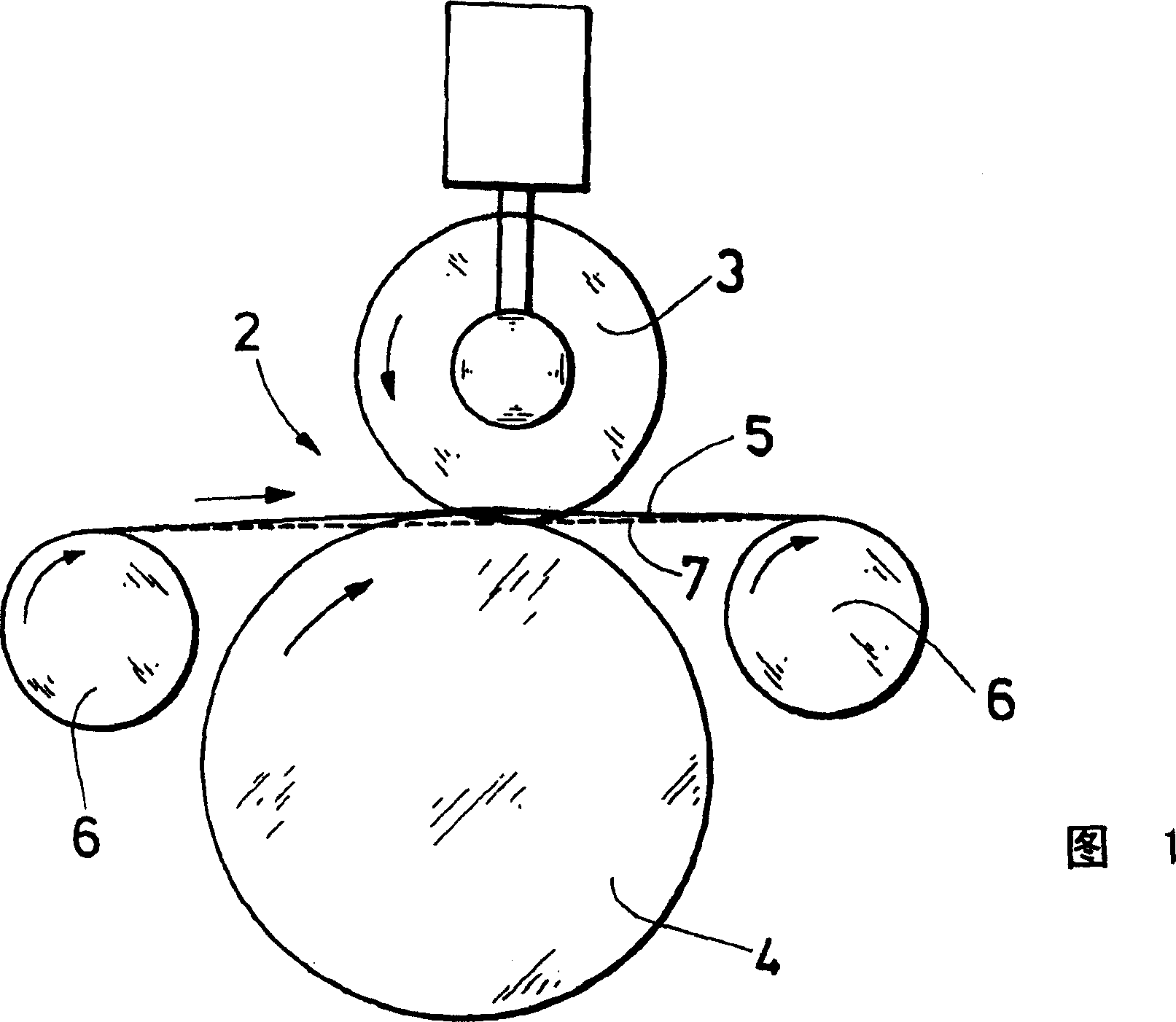

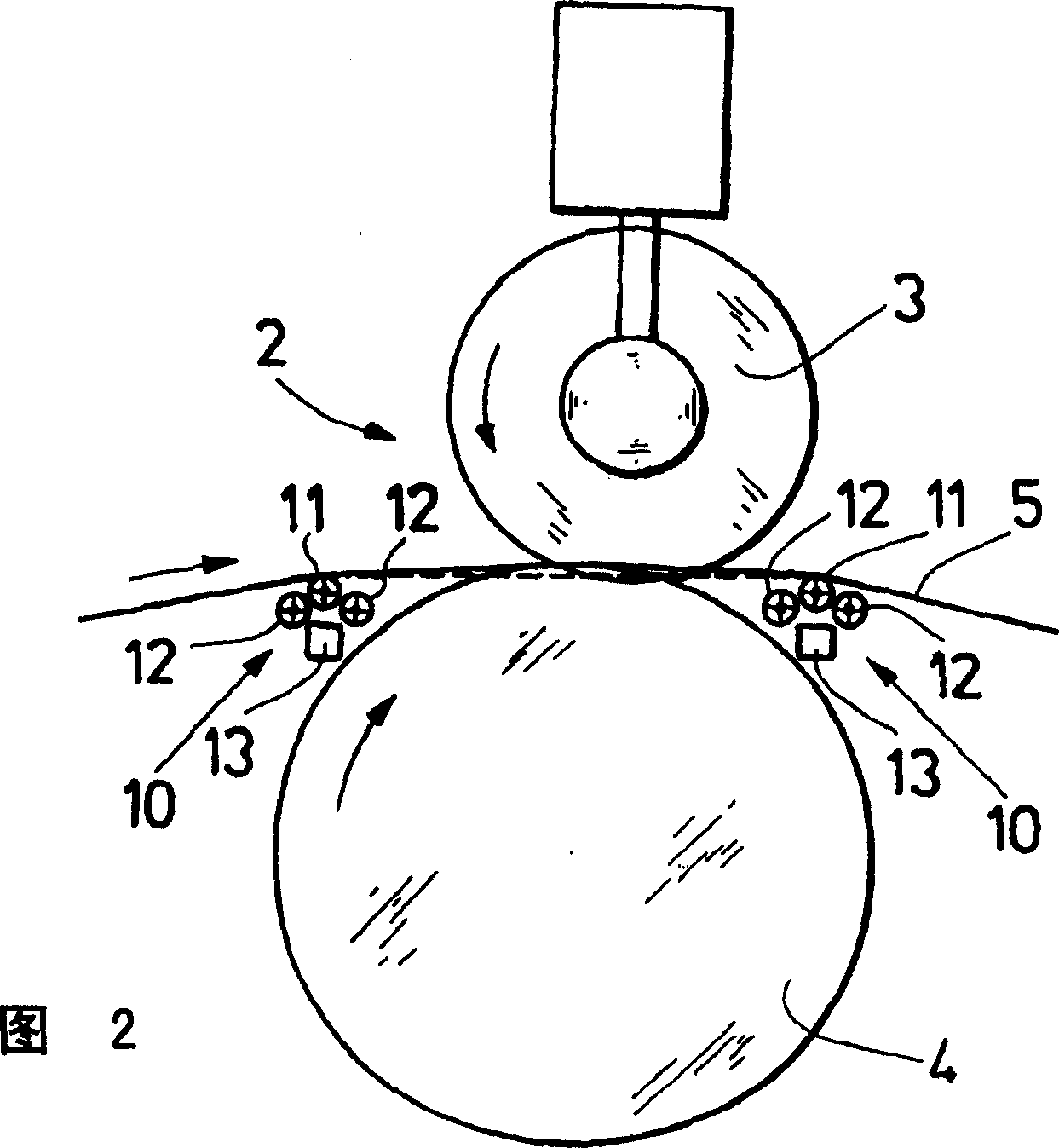

[0032] Figure 1 shows a cutting system for a sheet of paper 5 in a longitudinal cutting station of a paper processing machine. The longitudinal paper cutting station consists of a longitudinal cutting device 2 comprising an upper cutter 3 and a lower cutter 4 which tangentially cuts a sheet of paper passing between the lower cutter and the upper cutter.

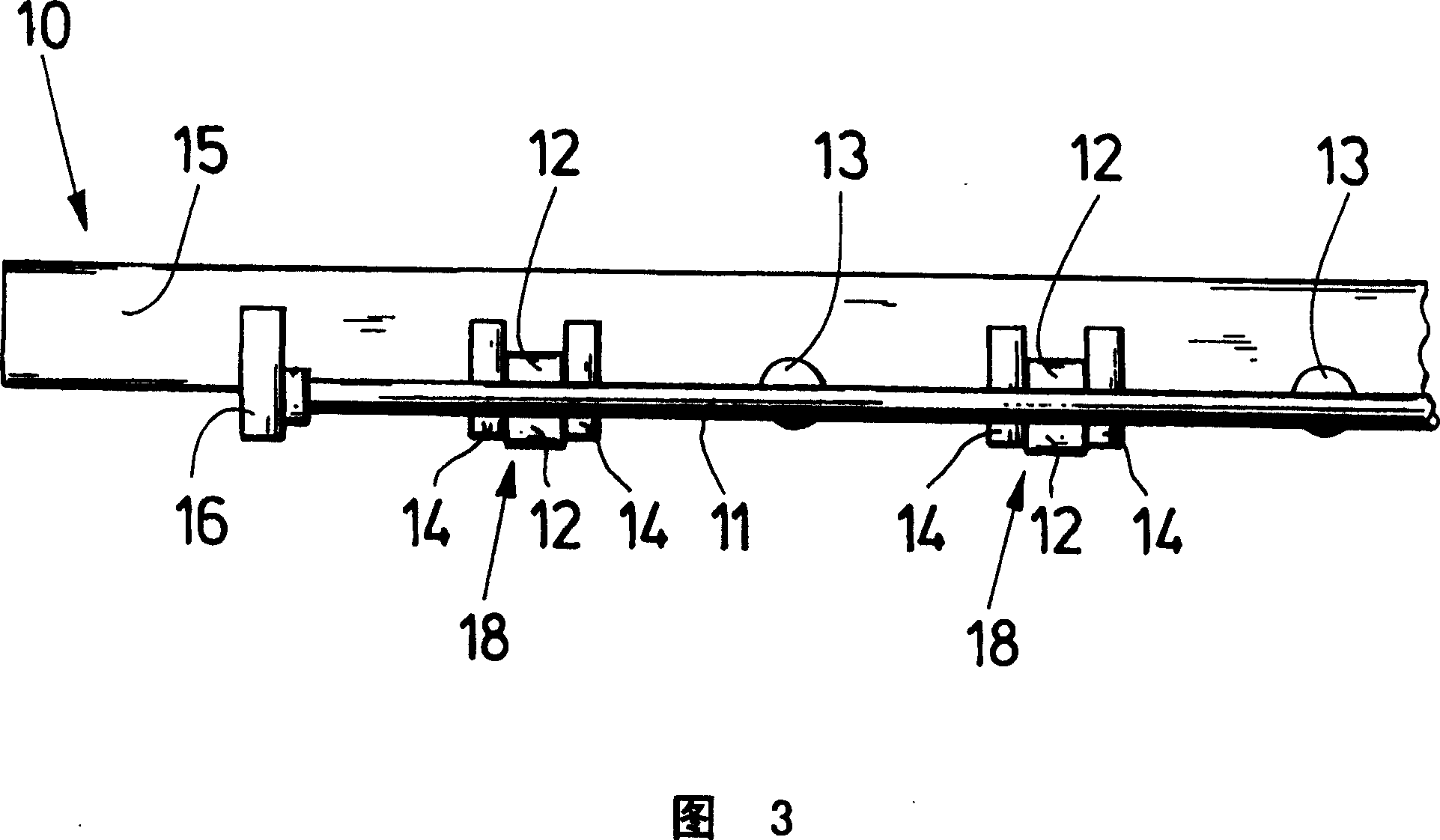

[0033] A supporting shaft 6 is arranged in each case in front of the longitudinal cutting device 2 and behind the longitudinal cutting device 2 in order to support the sheet 5 in the transverse direction, ie in a plane perpendicular to the drawing plane. Due to the width of the paper 5, sufficient stability of the support shafts 6 over the entire width of the paper is required, so these support shafts 6 are made with a relatively large diameter of up to 150 mm. Due to the large diameter of the support shafts 6 , these support shafts 6 can of course only be arranged at a correspondingly large distance from the tangent point of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com