Steel frame platform

A platform and steel frame technology, which is applied to the accessories of scaffolding, formwork/formwork/work frame, and on-site preparation of building components, etc. Highly adjustable and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

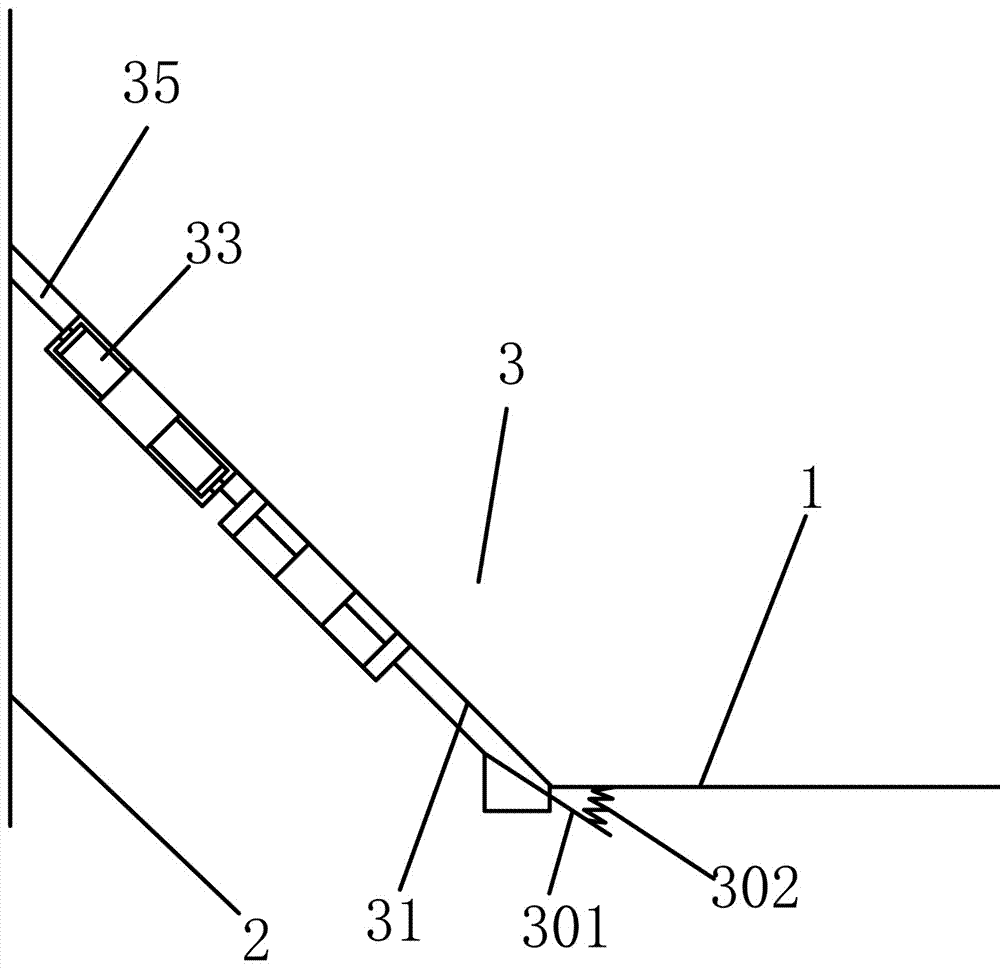

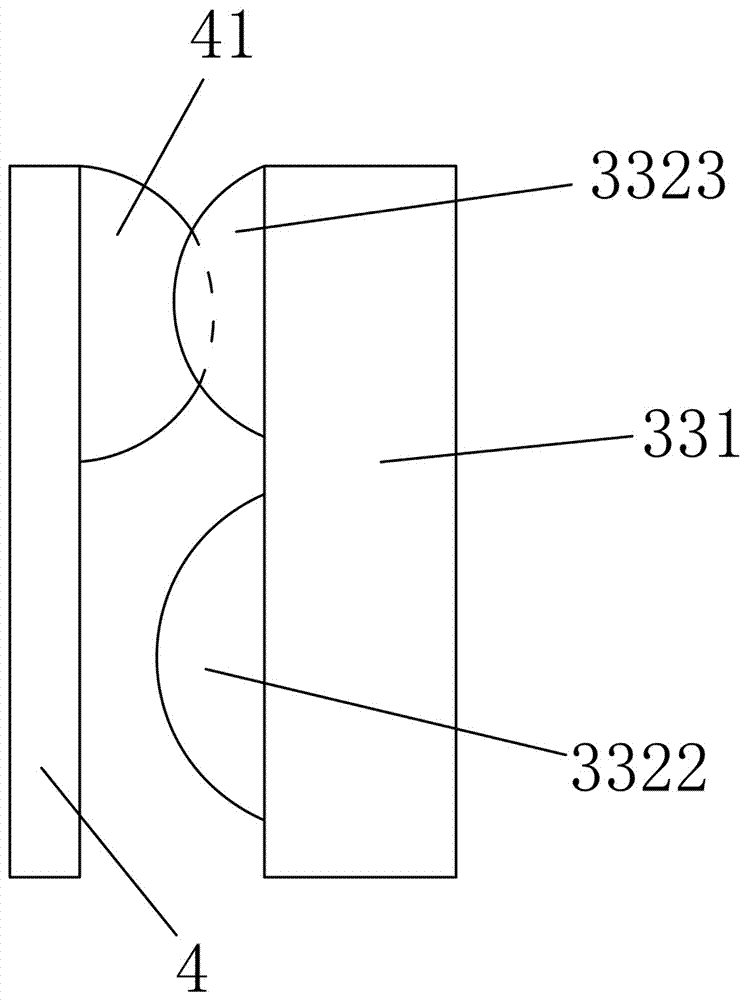

[0034] A steel frame platform, comprising a platform body 1, a plurality of flaps 3 hinged end-to-end to the edge of the platform body close to the wall 2, and an extension plate 10 detachably connected to the flap, the The flap includes a plate body 31, a lifting connecting piece that is arranged on both sides of the middle and upper part of the plate body and can be buckled with an adjacent plate body, and the lifting connecting piece includes a The open slot 32 is hinged on the notch of the slot and can be turned outward to the lifting handle 33 on the adjacent board through the hinge point; the middle part of the board is sunken to form a guide groove 35, and the guide groove is triangular. And near the end that the plate body is connected with the platform body is a narrowing part 351, and the end far away from the platform body is an expanding part 352, and the bottom of the narrowing part is concave to form the ash accumulation tank 9, and the ash accumulation tank is de...

Embodiment 2

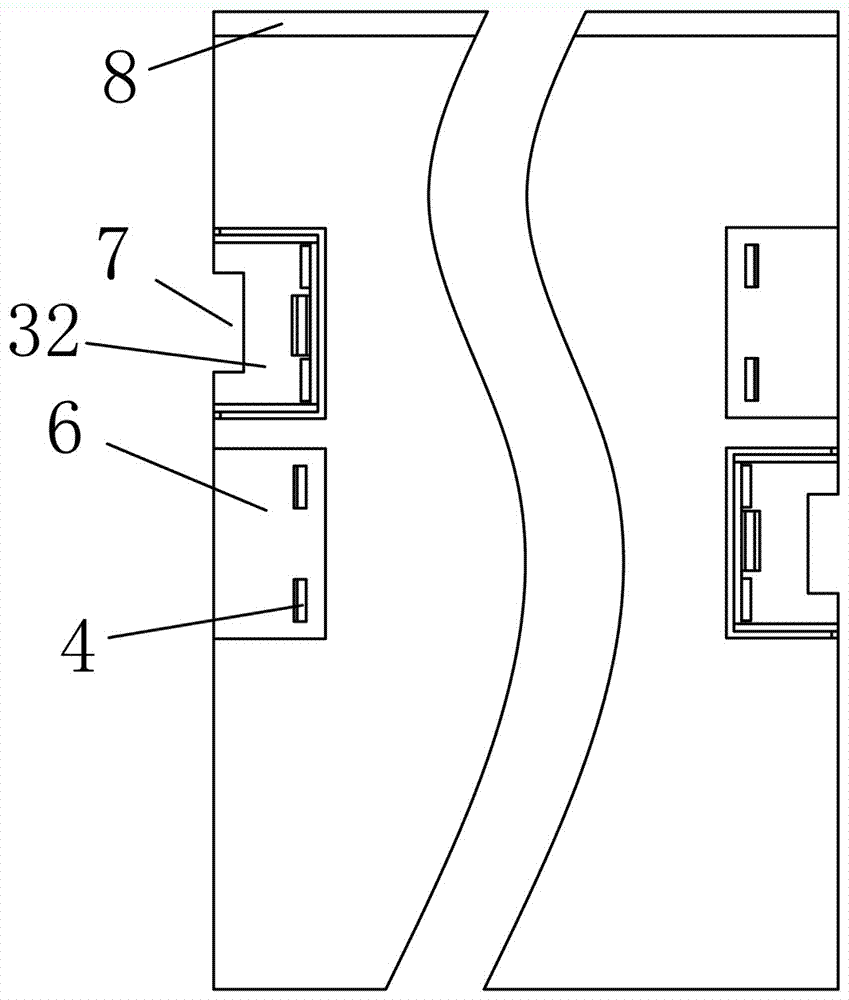

[0042] The difference from the above-mentioned embodiment is that a receiving groove 6 is opened on the adjacent plate body corresponding to the embedding groove, and a buckle plate 4 is arranged in the receiving groove corresponding to the position of the handle, and the convex wave part and the The shape of the hands of the card is the same; on the same side of the same board, an embedding groove and a receiving groove are sequentially arranged up and down, and on the other side, an accepting groove and an embedding groove are sequentially arranged up and down.

[0043] The receiving groove and the embedding groove are used to cooperate with the lifting handle to ensure that the lifting handle does not protrude from the board body, the flap and the platform can fit together, and at the same time can buckle the lifting handle, and can make the gap between adjacent flaps to connect.

Embodiment 3

[0045]The difference from the above-mentioned embodiment is that there is a lifting plate notch 7 on the bottom plate of the groove where the embedding groove is located at the notch position. The edge of the notch of the lifting plate is covered with a rubber skin 71 . At least the upper edge of the board is covered with a rubber strip 8 .

[0046] The rubber skin ensures that it is not easy to cut hands when holding it, and it is easy to flip the flap. The rubber strip has an anti-collision effect and can also protect the platform, board and wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com