Detection device and detection method of adhesion of galvanized layers of galvanized steel plates

A technology of galvanized steel sheet and detection device, applied in the direction of measurement device, mechanical device, instrument, etc., can solve the problems of lack of galvanized layer adhesion inspection process, cumbersome quality traceability procedure, body air bubbles, etc., to reduce zinc layer peeling off The effect of hidden dangers of quality defects, guaranteeing the adhesion requirements of the zinc layer, and reducing the hidden dangers of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Such as Figure 1 to Figure 4 The shown galvanized steel sheet galvanized layer adhesion detection device includes the following parts:

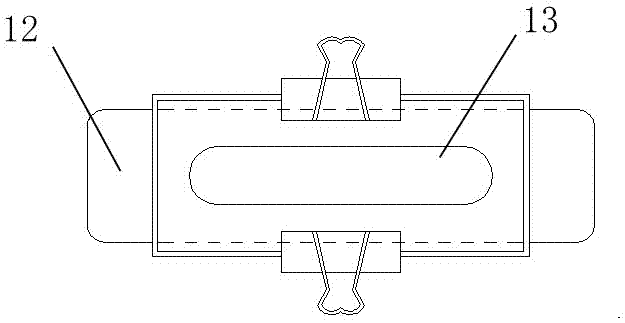

[0028] (1) High temperature resistant holder, used to clamp the galvanized sheet sample 12;

[0029] (2) Sealant, fill the waist-shaped hole of the high-temperature-resistant fixture with sealant, see glue application area 13, and make the sealant contact and adhere to the galvanized sheet sample 12;

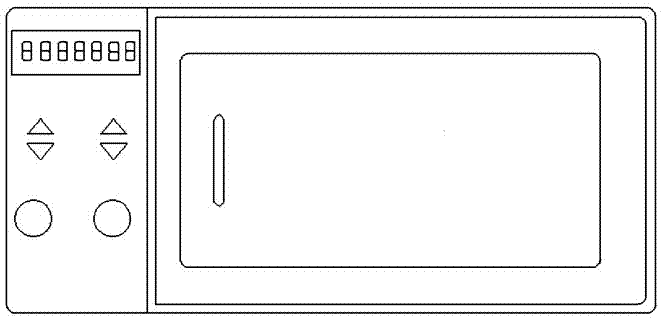

[0030] (3) Drying oven, used to bake the bonded galvanized sheet sample 12 and the high-temperature-resistant fixer in it, so as to harden the sealant;

[0031] (4) The bending fixture is used to bend the baked galvanized sheet sample 12 to separate the hardened sealant from the bent part of the galvanized sheet sample 12 .

[0032] The sealant adopts BETAMATE^TM structural glue.

[0033] The bending fixture includes a base 1, a rotating disk 2, a bending block 3, a fixed disk 4, a fixed block 5, a clamping block 6, a positioning blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com