A method for assembling and adjusting a mirror group

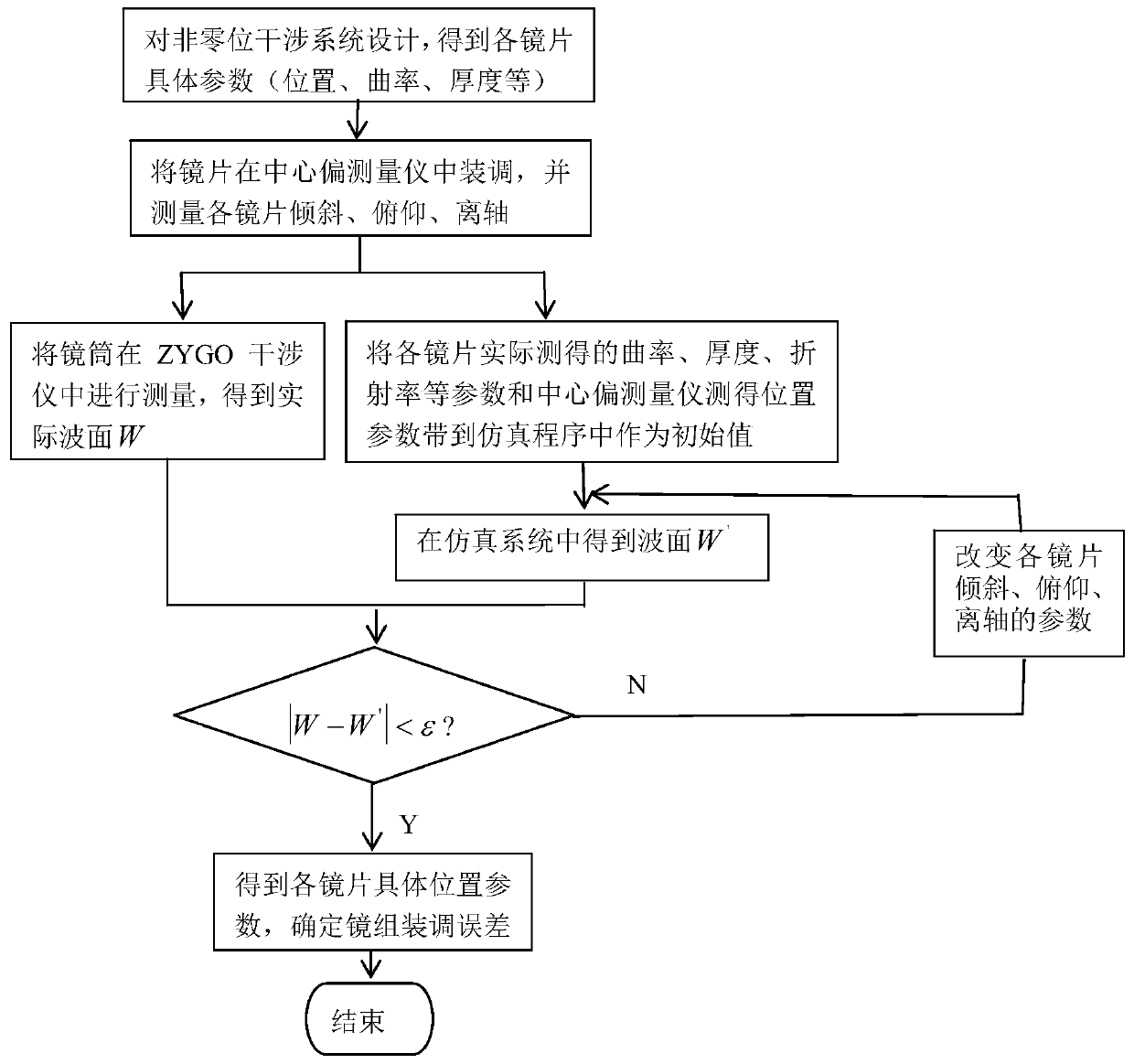

An assembly and adjustment method and mirror group technology, which are applied in the field of optical interferometry, can solve problems such as system errors and measurement results, and achieve the effects of improving accuracy, saving computing time, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

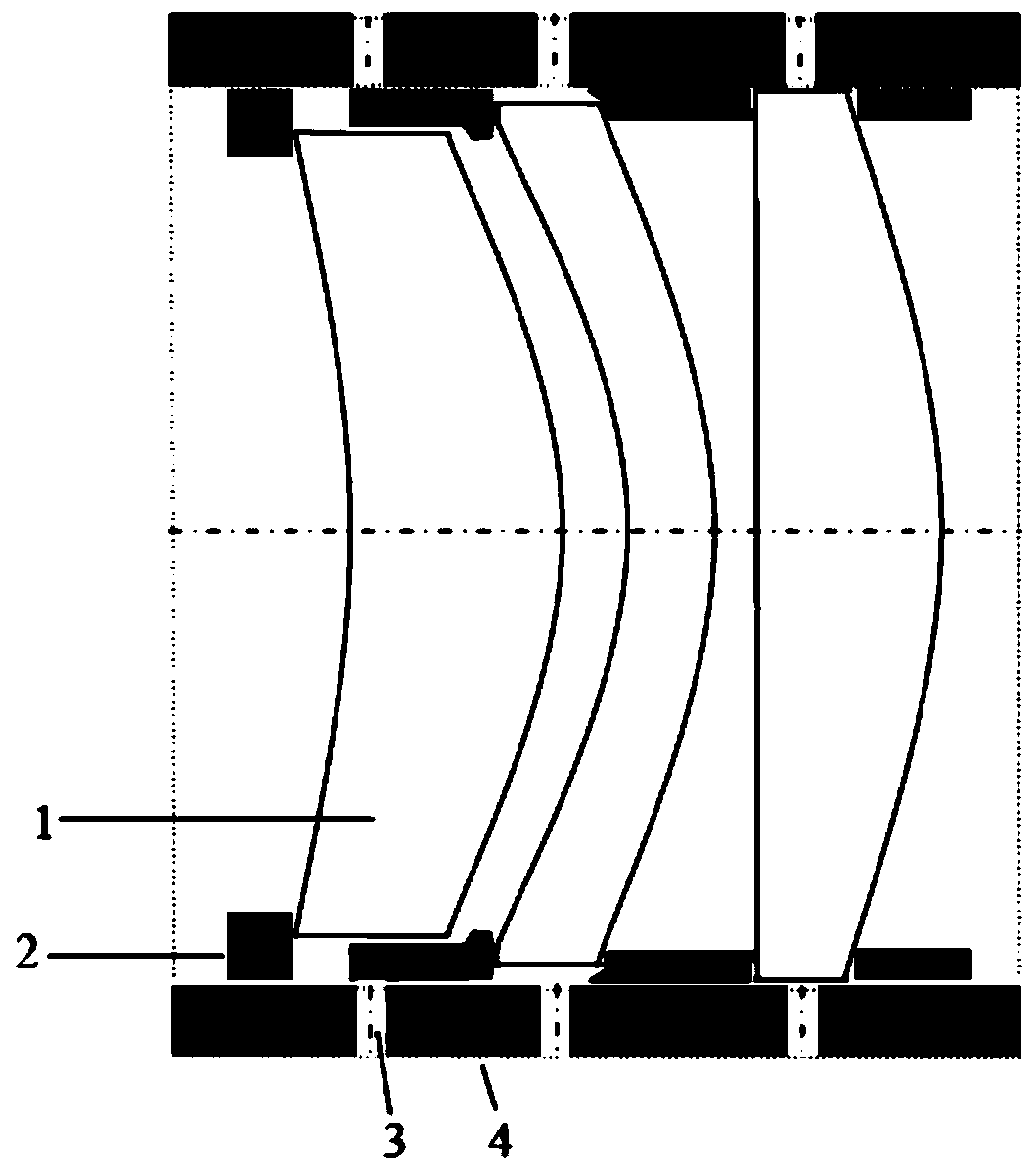

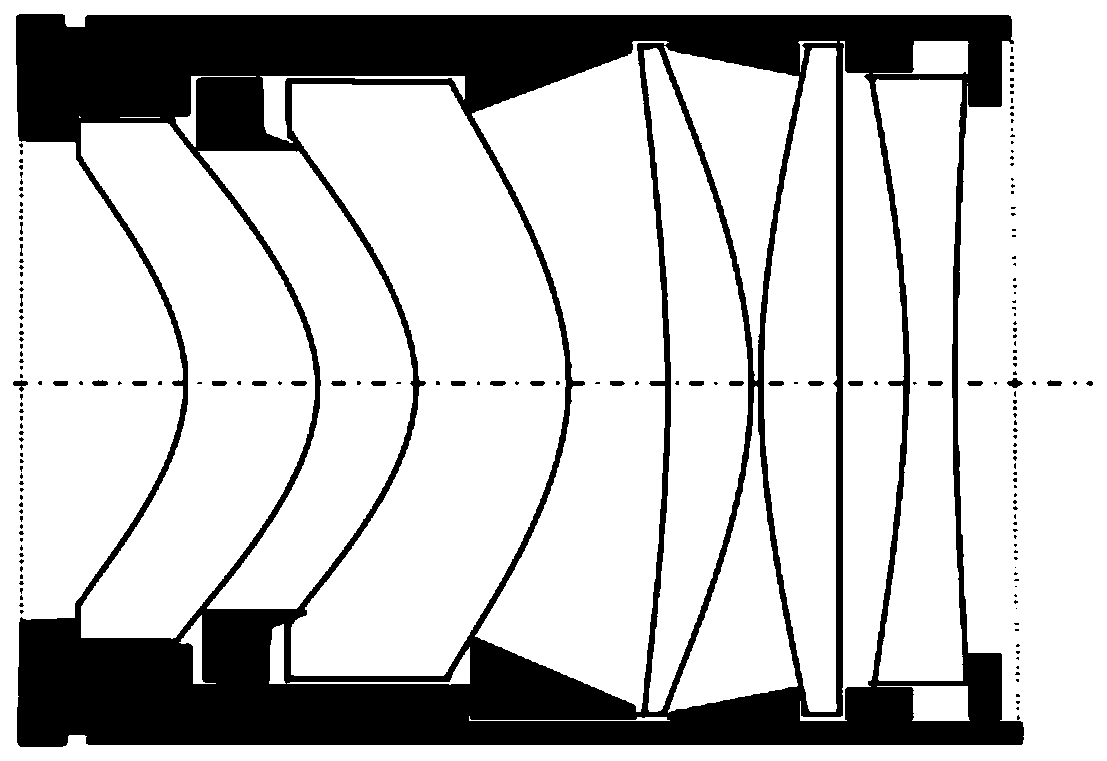

[0028] First, according to the designed lens, the mechanical structure of the lens barrel is designed, such as figure 2 In the collimator lens barrel shown, a spacer 2 is used to ensure the distance between each lens 1, and high-precision machining ensures that the tilt and pitch are infinitely close to zero, and the position of each lens 1 will have a symmetrical position The four adjustment screws 3 are screwed into the straight thread against the lens 1. In the center deviation measuring instrument, the center position of the lens 1 can be adjusted by changing how much each adjustment screw 3 is screwed in, and the center of the lens 1 is aligned with the whole After the optical axes of the lens barrels 4 coincide, the adjusting screws 3 are tightened, so that each lens 1 can be fixed in the lens barrel 4 . The specific process is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com