Method for Improving Imaging Quality of Off-Axis Three-mirror Optical System

An optical system, off-axis three-mirror technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of optical component position error, asymmetry, missing part of the central optical axis of the mirror, etc., to reduce the impact and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

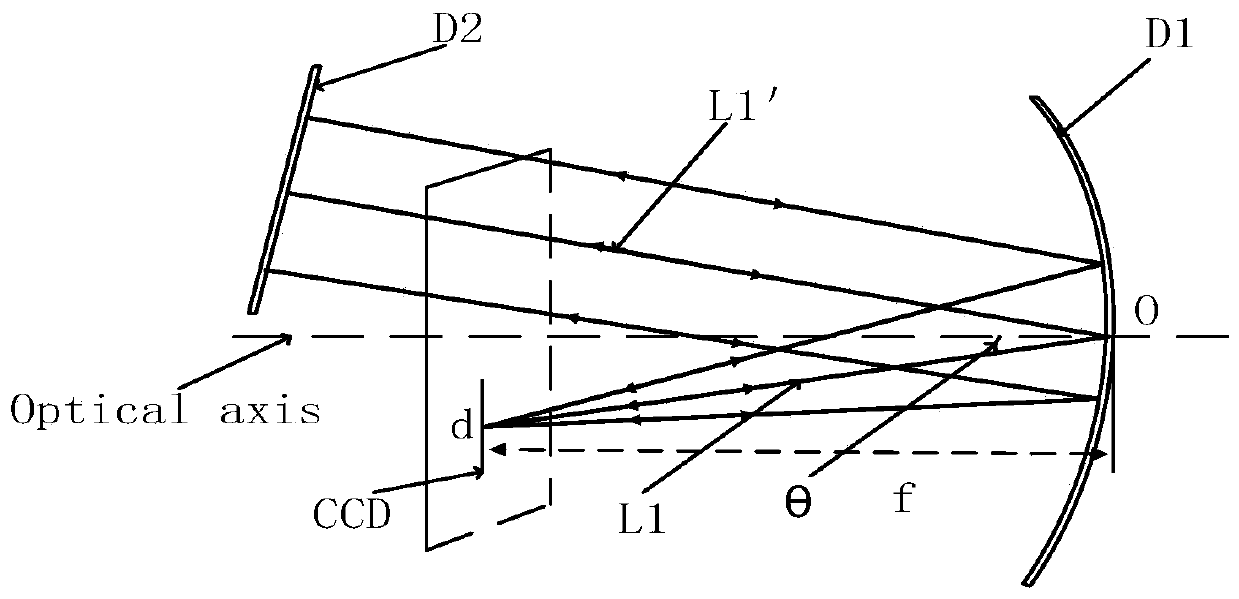

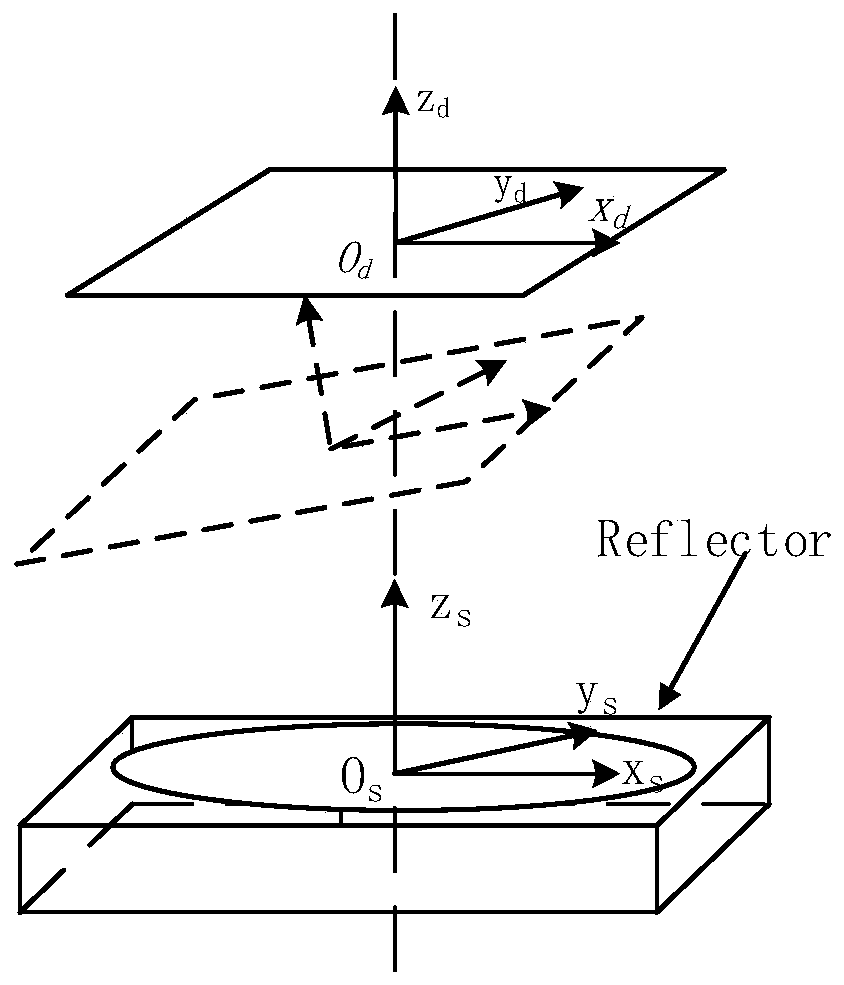

[0047] The technical problem of the present invention is: a theoretical research method for the relationship between the position change of the visual axis of an off-axis three-mirror optical system and the imaging position of the system. The imaging position compensation of the off-axis three-mirror optical system can be realized, and the imaging quality of the system can be improved.

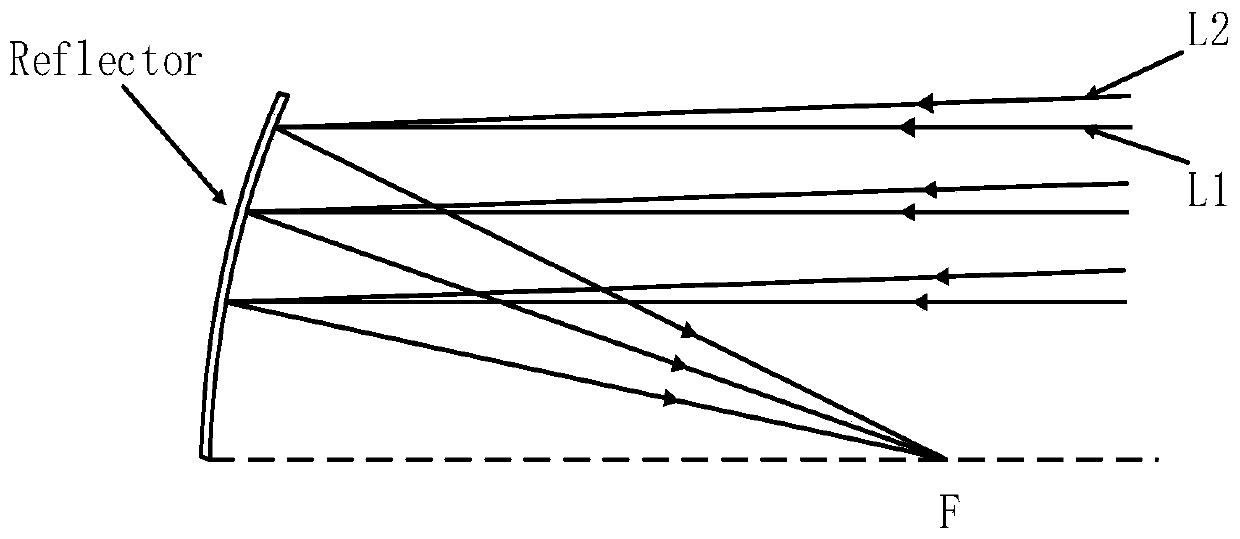

[0048] The technical scheme of the present invention is as follows: theoretically analyze the influence of the change of the visual axis on the imaging of the system, because the imaging optical path of the off-axis three-mirror optical system is complicated, the present invention proposes to equate the off-axis three-mirror system to a single-reflection system, and establish a reference mirror Imaging model, using equivalent and coordinate conversion mathematical methods to theoretically derive imaging formulas. The point light source passes through the reflector D1 and the reference reflecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com