Self-aligned super-junction structure and preparation method thereof

A self-alignment and doping type technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of relatively large fluctuations in final product parameters, strict control requirements, and low process compatibility, and achieve high stability of product parameters , good process compatibility and wide process specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

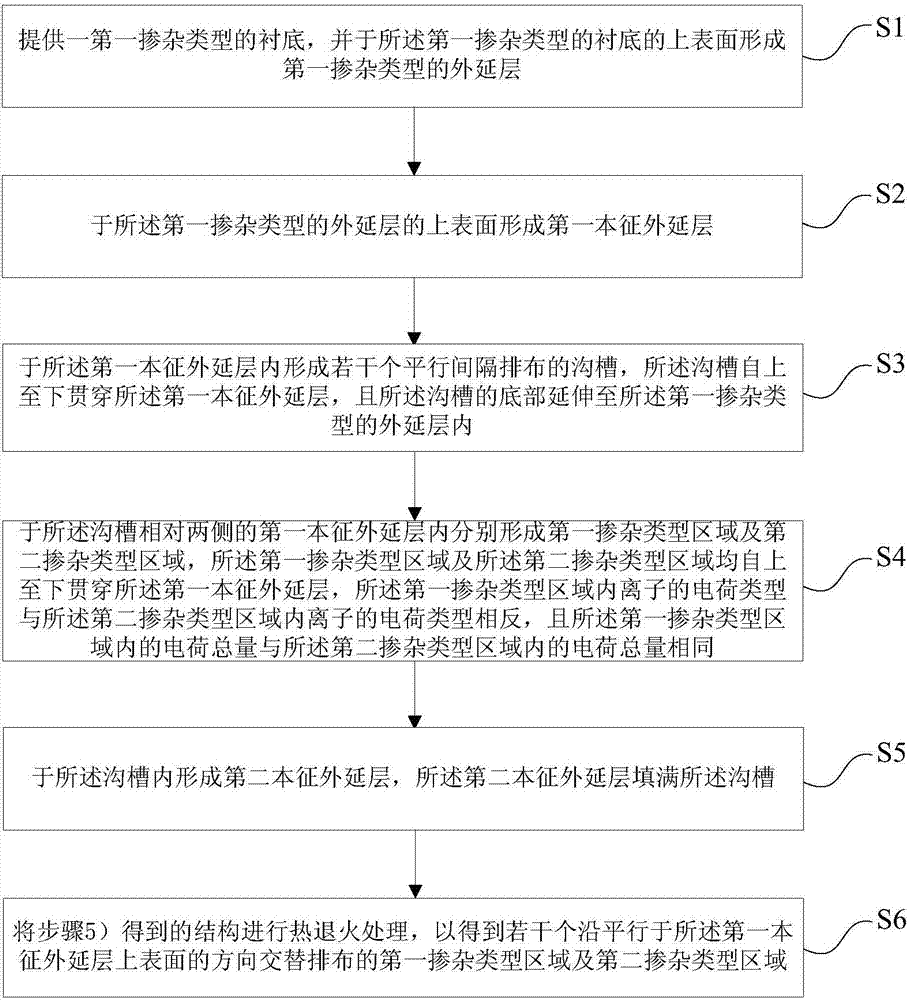

[0046] see figure 1 , this embodiment provides a method for preparing a self-aligned super-junction structure, the method for preparing a self-aligned super-junction structure includes the following steps:

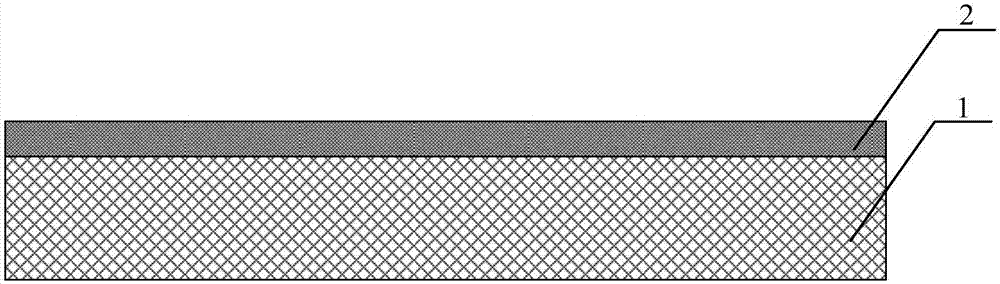

[0047] 1) providing a substrate of the first doping type, and forming an epitaxial layer of the first doping type on the upper surface of the substrate of the first doping type;

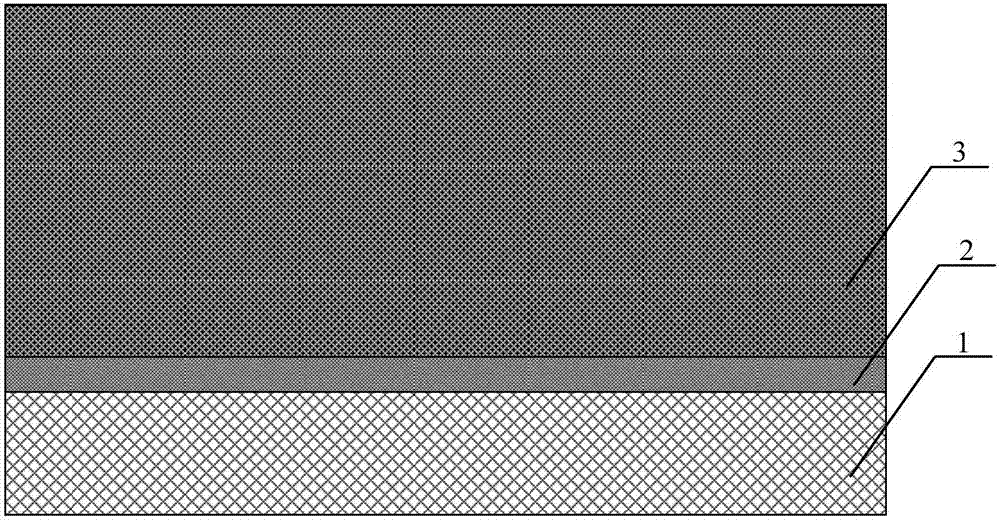

[0048] 2) forming a first intrinsic epitaxial layer on the upper surface of the epitaxial layer of the first doping type;

[0049] 3) Forming several trenches arranged in parallel at intervals in the first intrinsic epitaxial layer, the trenches penetrate the first intrinsic epitaxial layer from top to bottom, and the bottoms of the trenches extend to In the epitaxial layer of the first doping type;

[0050]4) A first doping type region and a second doping type region are respectively formed in the first intrinsic epitaxial layer on opposite sides of the trench, and the first doping type region...

Embodiment 2

[0086] read on Figure 1 to Figure 10 , this embodiment provides a self-aligned super-junction structure, and the self-aligned super-junction structure is prepared by the preparation method described in Embodiment 1.

[0087]In summary, the self-aligned superjunction structure and its preparation method of the present invention include the following steps: 1) providing a substrate of the first doping type, and forming a substrate on the substrate of the first doping type Forming an epitaxial layer of the first doping type on the surface; 2) forming a first intrinsic epitaxial layer on the upper surface of the epitaxial layer of the first doping type; 3) forming several epitaxial layers in the first intrinsic epitaxial layer trenches arranged in parallel at intervals, the trenches penetrate the first intrinsic epitaxial layer from top to bottom; 4) forming first doped type region and the second doping type region, the first doping type region and the second doping type region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com