Motor dual-bearing structure with dual-lubricating system

A double-lubrication, double-bearing technology, applied in the direction of lubricating parts, engine lubrication, casing/cover/support, etc., can solve the problem of unable to achieve the amount of greasing, the tortuous and complicated waste oil passage, and the unfavorable discharge of waste oil, etc. problems, to achieve the effect of heat dissipation, discharge, and simplification of the discharge path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

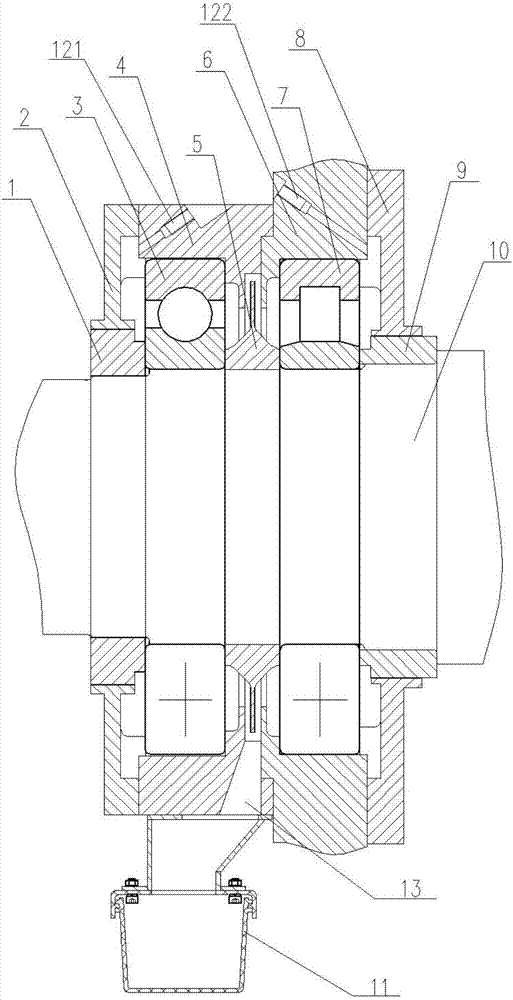

[0022] figure 1 It is a double bearing structure for a motor with a double lubrication system according to an embodiment of the present invention. Such as figure 1 As shown, the double bearing structure for the motor with double lubrication system includes a rotating shaft 10, an inner bearing chamber 6, an outer bearing chamber 4, an inner bearing 7, an outer bearing 3, an inner bearing cover 8, an inner oil seal 9, and an outer bearing cover 2 , Outer oil seal 1, grease regulator 5 and waste oil box 11.

[0023] In this embodiment, the outer bearing 3 is a deep groove ball bearing, and the inner bearing 7 is a cylindrical roller bearing. In other embodiments, the outer bearing 3 is a cylindrical roller bearing, and the inner bearing 7 is a deep groove ball bearing. An inner bearing 7 , a grease regulator 5 and an outer bearing 3 are sheathed on the rotating shaft 10 . The grease regulator 5 is located between the inner bearing 7 and the outer bearing 3 . The two side su...

Embodiment 2

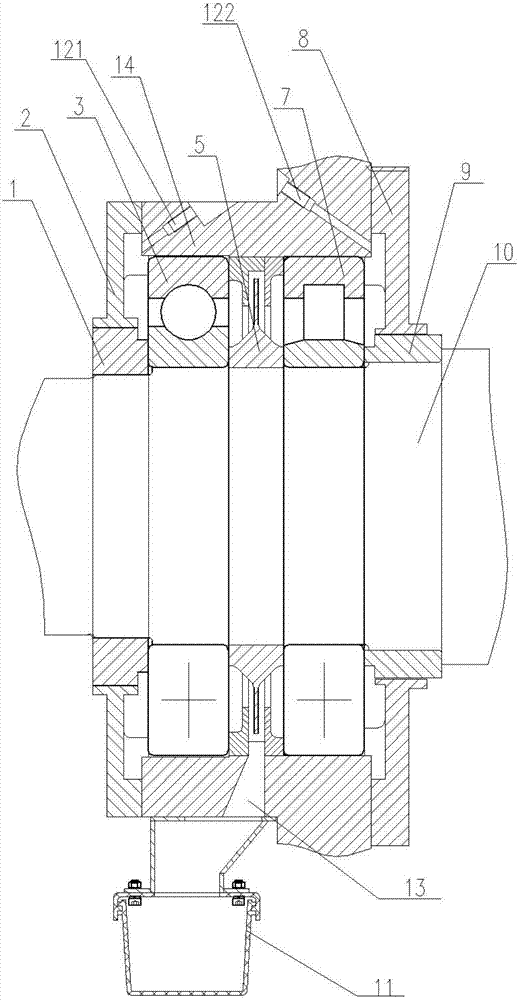

[0026] Such as figure 2 As shown, on the basis of the first embodiment, the outer bearing chamber 4 and the inner bearing chamber 6 of the split structure in the first embodiment are combined into an integral structure as the bearing chamber 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com