A special ridging and grooving machine for shallow yam planting method

A planting method and technology of a ridge and groove machine, which are applied in the directions of botanical equipment and methods, application, plant cultivation, etc., can solve the problems of reduced yield, lack of mechanization, and high manufacturing cost of bamboo, to reduce labor intensity and ensure planting. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The superficial yam planting method of the present embodiment is carried out as follows

[0028] The first step, soil preparation and fertilization - choose a fertile, loose, and convenient field for drainage and irrigation, and apply decomposed livestock and poultry manure organic fertilizer 1000±50kg / mu or 45% ternary compound fertilizer (N: P: K each 15% ) 25 ±5kg / mu.

[0029] The second step, ridge-pressing trough—use a ridge-pressing trough machine to build a planting ridge with an inclined slope, and press out arc-bottomed planting troughs with a depth of 10 cm and a spacing of 25 cm on the slope; years of tests have shown that 25 cm is suitable for yam The highest acceptable planting density for planting characteristics to maximize yam yield.

[0030] The third step is to place the seeds in the trough - place the hard directional trough that matches the shape of the arc bottom planting trough along the planting trough, cover the soil with 2-3CM, and select healt...

Embodiment 2

[0039] The present embodiment wishes to obtain about 40cm long after the yam is molded, so it needs to be as follows: Figure 8 , Figure 9 As shown, construct an isosceles triangular double-sided slope with an inclination angle of 30±5º, a slope length of 55±5CM, and a ridge spacing of 40-80CM.

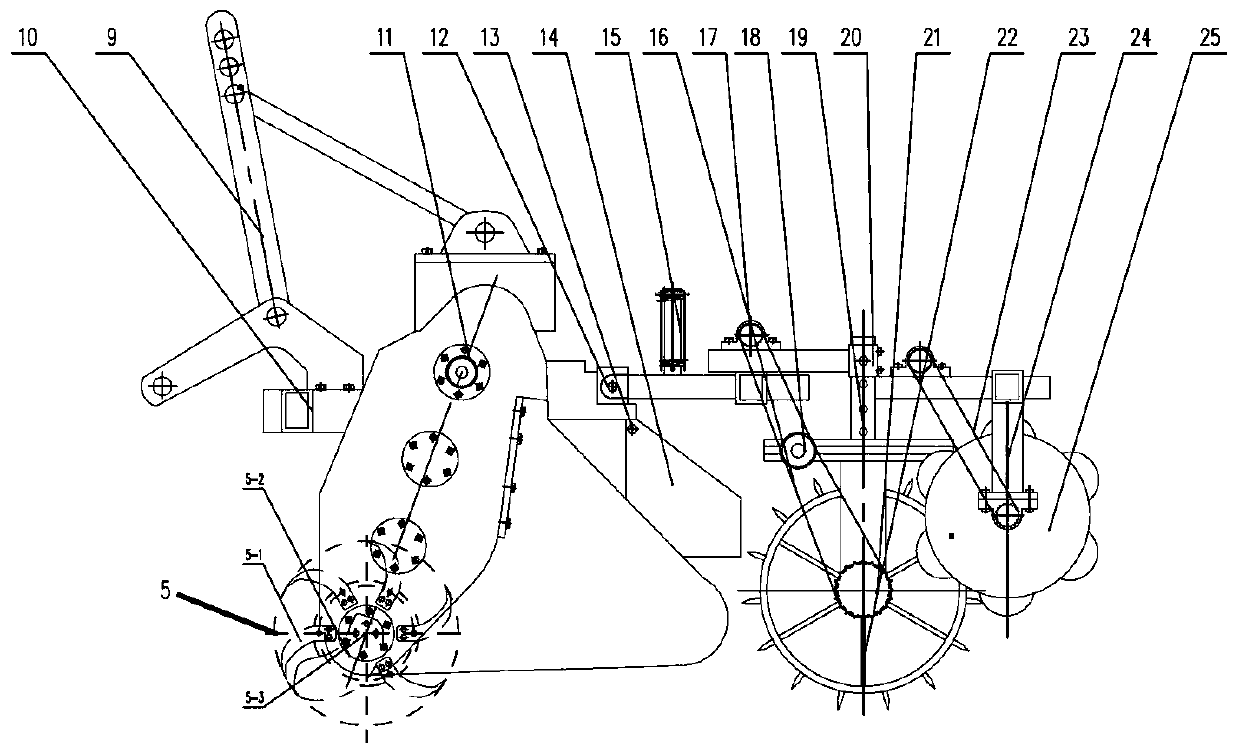

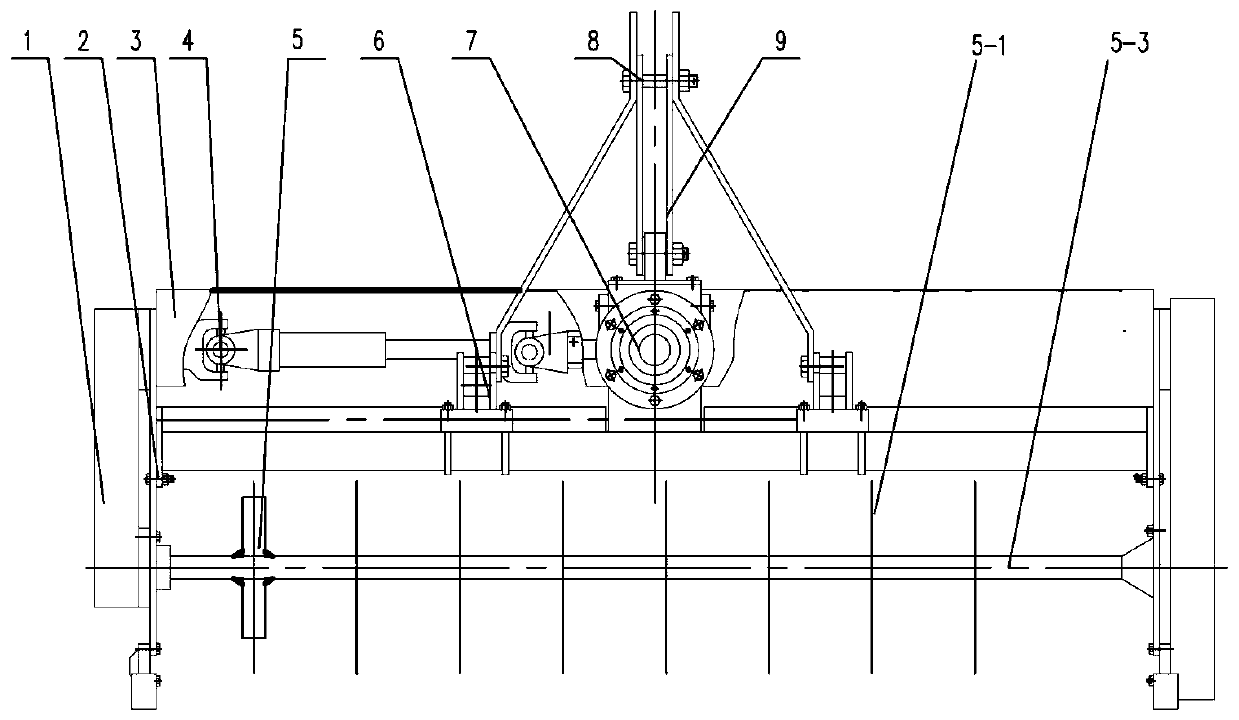

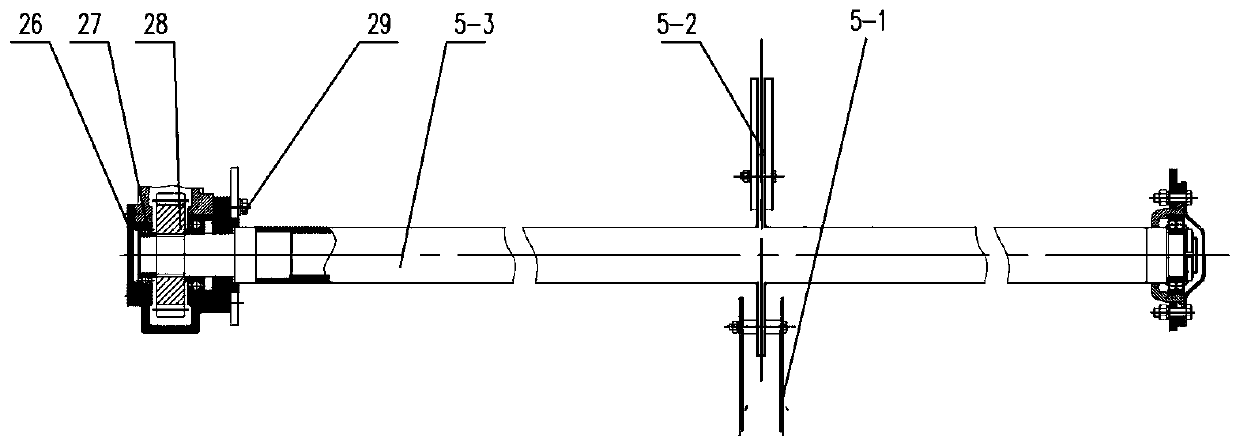

[0040] The superficial yam planting method that adopts is identical with embodiment one, and difference is that special-purpose ridging groove machine has change, as Figure 7 As shown, the single pressure roller of the dedicated ridge-grooving machine in Embodiment 1 is changed to a pair of pressure rollers distributed in a figure-eight shape. In fact, this embodiment and the first embodiment have one machine with two functions. First, the positions of the eight rotary tillage and ridging knife combinations on the rotary tillage and ridging assembly 5 are adjusted, and the two middle rotary tillage and ridging knife combinations are respectively It is composed of six pairs of rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com