Smoke prevention and exhaust pipeline cleaning robot

A duct cleaning and robot technology, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of observing the cleaning effect, poor smoke exhaust in the kitchen, backwardness, etc., and achieves modularization and operation. Reasonable and convenient , convenient for external viewing and monitoring, and the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

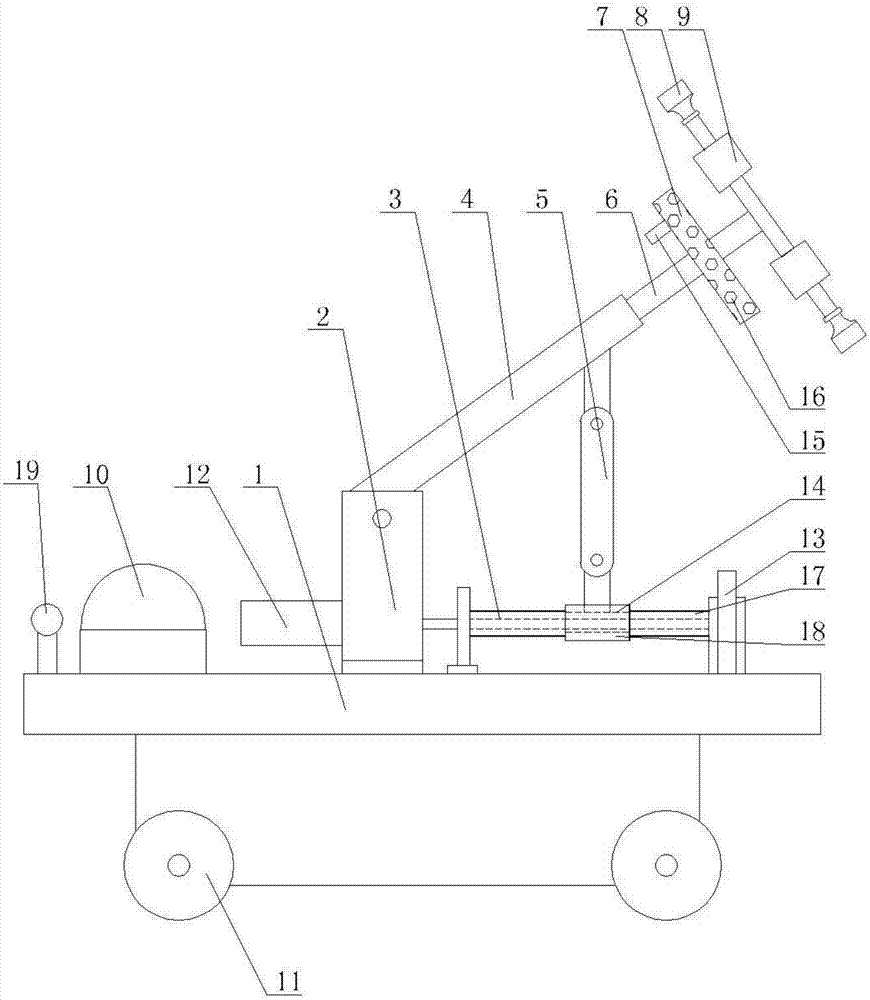

[0028] Such as figure 1 As shown, a smoke prevention pipe cleaning robot includes a mobile car 1 and a control system. The lower part of the mobile car 1 is provided with a walking control mechanism, and the upper part of the mobile car 1 is provided with a bracket 2, a camera 10 and a light bulb 19. A cleaning arm lifting mechanism is installed; the walking control mechanism includes four DC deceleration motors and four rollers 11, and the four rollers 11 are evenly arranged on the bottom of both sides of the movable trolley 1, and the four DC deceleration motors pass through four and a half rollers respectively. The shaft controls the rotation of four rollers 11; the cleaning arm lifting mechanism includes a lifting motor 12, a screw mandrel 3, a threaded pipe 14, a support arm 5 and a cleaning arm, and the lifting motor 12 and the screw mandrel 3 are horizontally fixed on the support 2, and the lifting motor 12 controls the rotation of the screw mandrel 3, the support arm 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com