Drying controlling method of clothes drying device and clothes drying device

A drying device and drying control technology are applied in the fields of drying control of a clothes drying device and drying stop control of a clothes drying device, which can solve the problems of low detection accuracy and inability to directly detect the motor load, etc. The detection structure is simple, the cost is stable and reliable, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

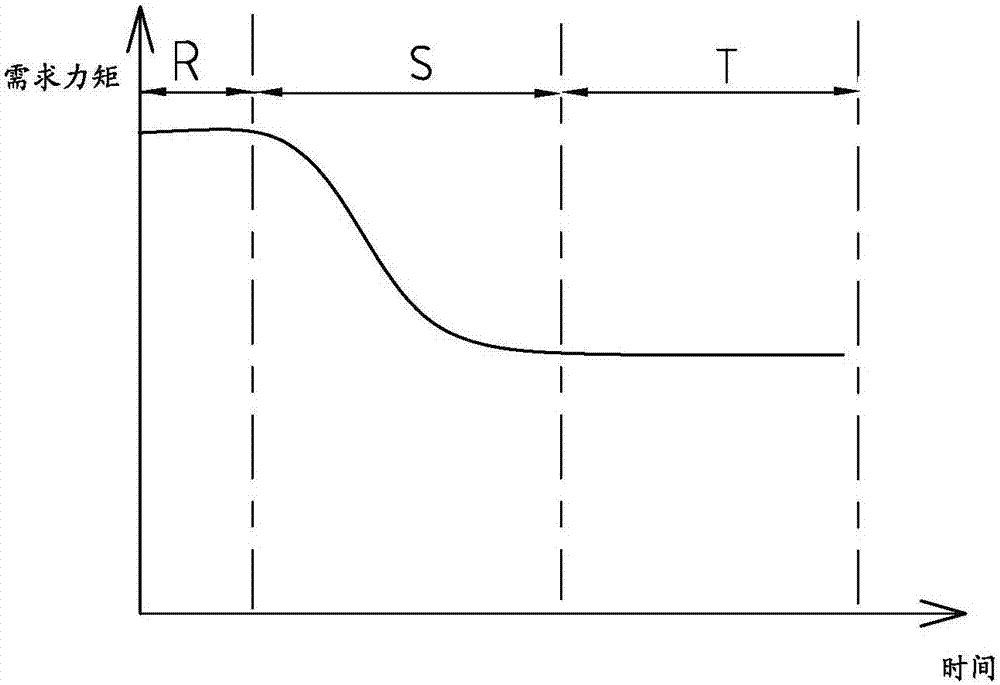

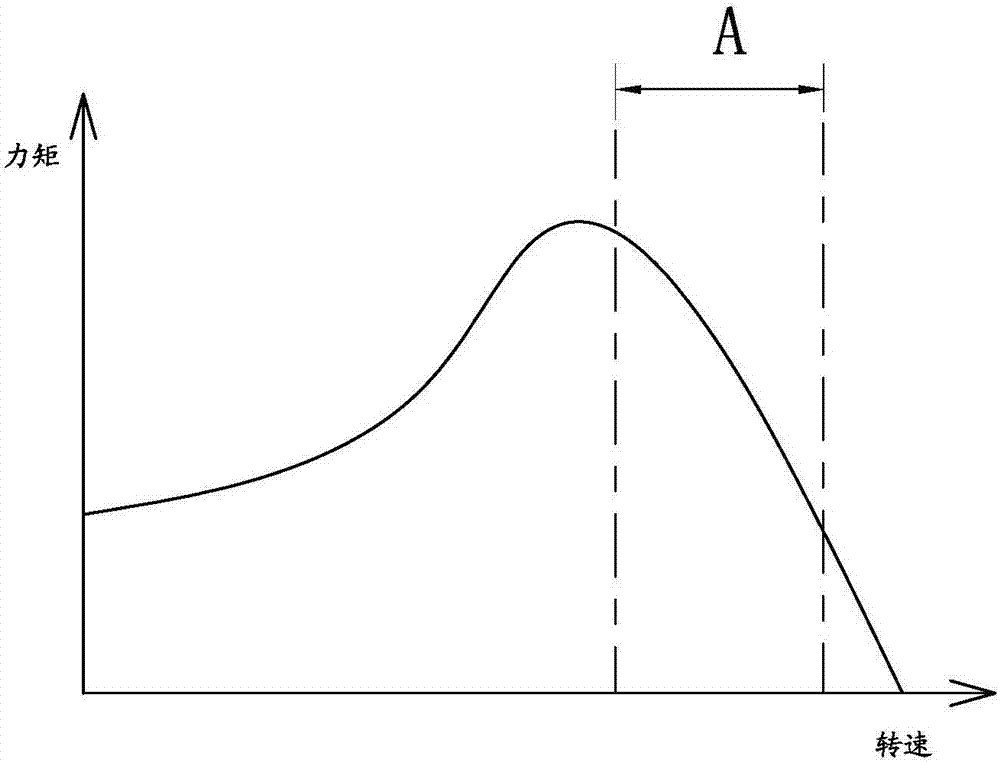

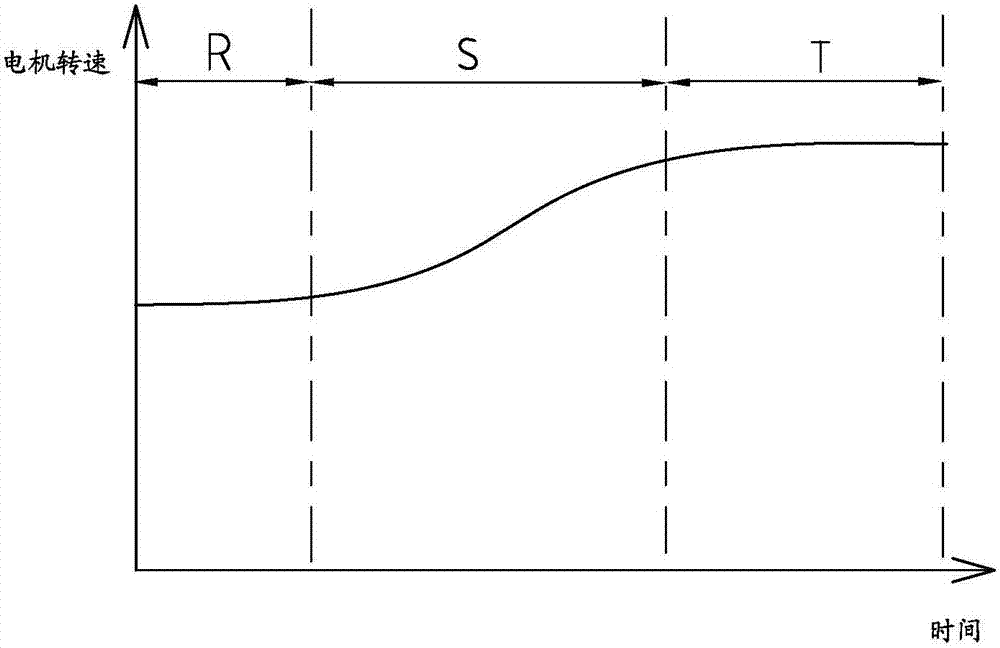

[0030] This embodiment provides a drying control method for a clothes drying device. The clothes drying device includes a motor that drives the clothes to rotate, a speed detector that detects the speed of the motor, and a controller that controls the operation of the motor. The controller has a timer device and counter, and the speed measuring device is connected with the controller. The drying device of the present invention uses the motor to drive the drying barrel to rotate, and the clothes are continuously turned over in the drying barrel to completely evaporate the moisture in the clothes, and finally complete the drying. The drying process of the drying device is divided into three stages, The starting stage R, the drying stage S and the drying completion stage T, the present invention mainly detects and judges the drying stage S and the drying completion stage T.

[0031] Such as figure 1 As mentioned above, is the time change diagram of the demand torque of the dryin...

Embodiment 2

[0045] This embodiment provides a clothes drying device, which uses the drying control method of the clothes drying device in any of the above embodiments to control the drying of clothes, especially a washing machine with a dryer, which includes a casing, an outer A barrel, an inner barrel, and a controller located above the outer barrel and connected to the housing, the inner barrel is connected to the motor as a drying barrel, and the washing machine performs washing, dehydration, and drying of clothes in sequence, using the existing controller and rotating speed The tester can also realize the dehydration control of the washing machine. Also according to the influence of the weight reduction of the clothes on the motor speed during the dehydration process, the two stages of dehydration and drying are controlled by detecting the speed, reducing the number of parts of the whole washing machine. Interference during component installation and operation is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com