Service-life judging method for filter of filtration-type machine set and filtration-type machine set

A filter and filtering technology, which is applied in heating methods, household heating, lighting and heating equipment, etc., can solve the problems of high cost of the unit, no output air volume of the unit, and great influence on the accuracy of the sensor, so as to reduce the replacement waste, Precise service life and workload-avoiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

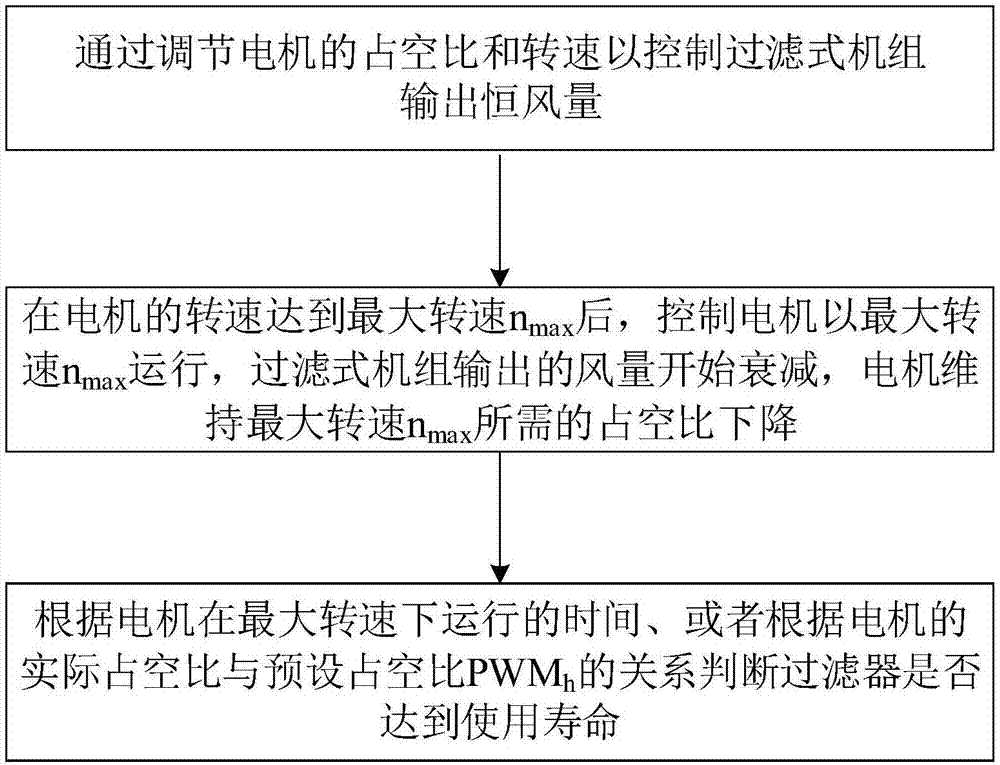

Method used

Image

Examples

specific Embodiment approach

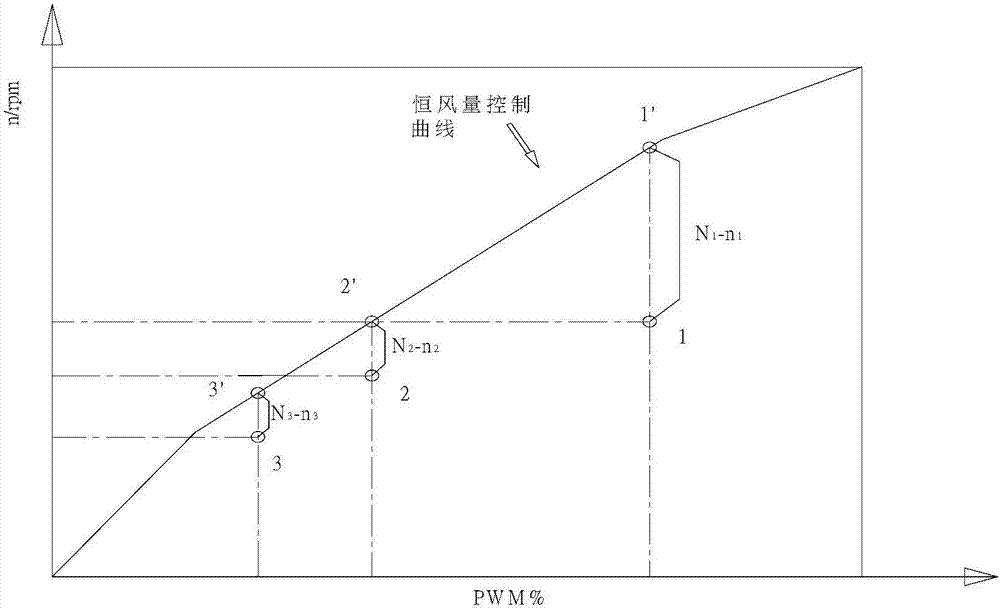

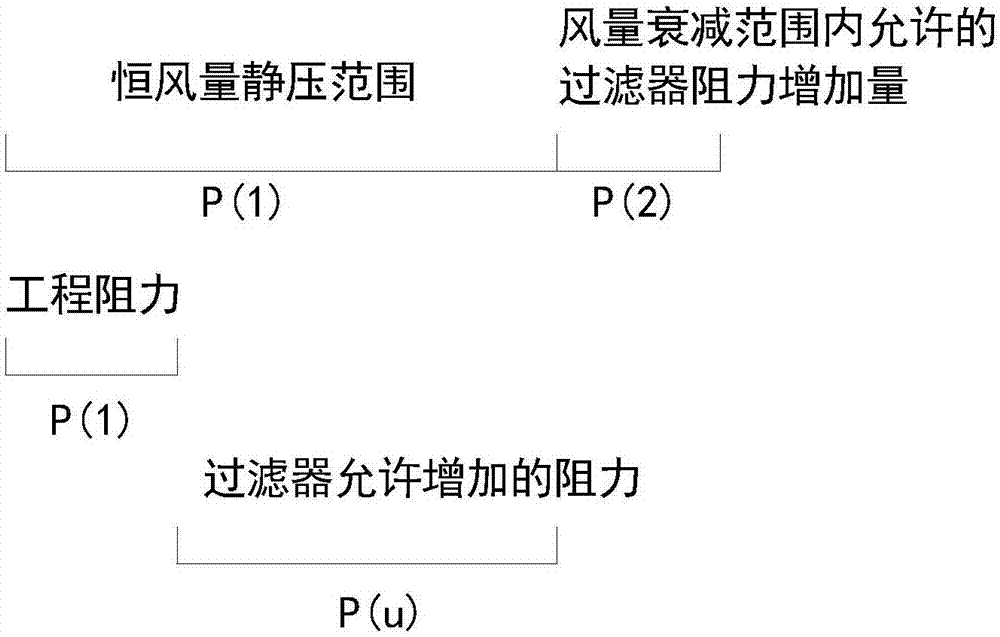

[0056] That is, in order to eliminate the influence of engineering installation variables on the judgment of filter life, corresponding corrections can be made. The specific implementation method is as follows: the unit remembers the initial speed N under the rated air volume before the engineering installation x And the corresponding duty cycle PWM x value. Set the initial operation debugging function of the unit. After the project installation is completed, start the initial operation function debugging, enter the constant air volume debugging and stabilization, and record the stable output speed N x+1 And the corresponding stable duty cycle PWM x+1 . Using speed N x+1 and duty cycle PWM x+1 The rated air volume static pressure-rotational speed curve (such as Figure 4 As shown), the engineering resistance P(y) at the rated air volume can be judged.

[0057] If P(y) is less than or equal to the allowable value P(x) (the unit is preset at the factory), the unit has bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com